Fiberglass Jeep Bodies For Sale: Your Ultimate Guide to Rust-Free Adventures

Fiberglass Jeep Bodies For Sale: Your Ultimate Guide to Rust-Free Adventures jeeps.truckstrend.com

The iconic Jeep, a symbol of freedom, ruggedness, and off-road prowess, has captivated enthusiasts for generations. However, time, trails, and Mother Nature often take their toll, leaving beloved steel bodies susceptible to the dreaded enemy: rust. For many Jeep owners, particularly those restoring vintage CJ models or custom-building their dream rig, finding a solid, rust-free body can be an insurmountable challenge. This is where fiberglass Jeep bodies for sale emerge as a revolutionary and increasingly popular solution, offering a durable, lightweight, and perpetually rust-free alternative that breathes new life into classic designs.

A fiberglass Jeep body is essentially a replica of the original steel tub and often includes accompanying panels like fenders, hoods, and tailgates, meticulously molded from fiberglass composite. This modern material, composed of glass fibers embedded in a resin matrix, provides exceptional strength-to-weight ratio and, crucially, complete immunity to rust and corrosion. Whether you’re a seasoned restorer aiming for a pristine, period-correct look, an off-road enthusiast seeking a lighter, more resilient platform, or simply a passionate owner looking to extend the life of your cherished vehicle, exploring fiberglass options can open up a world of possibilities for your next Jeep project.

Fiberglass Jeep Bodies For Sale: Your Ultimate Guide to Rust-Free Adventures

What Exactly Are Fiberglass Jeep Bodies?

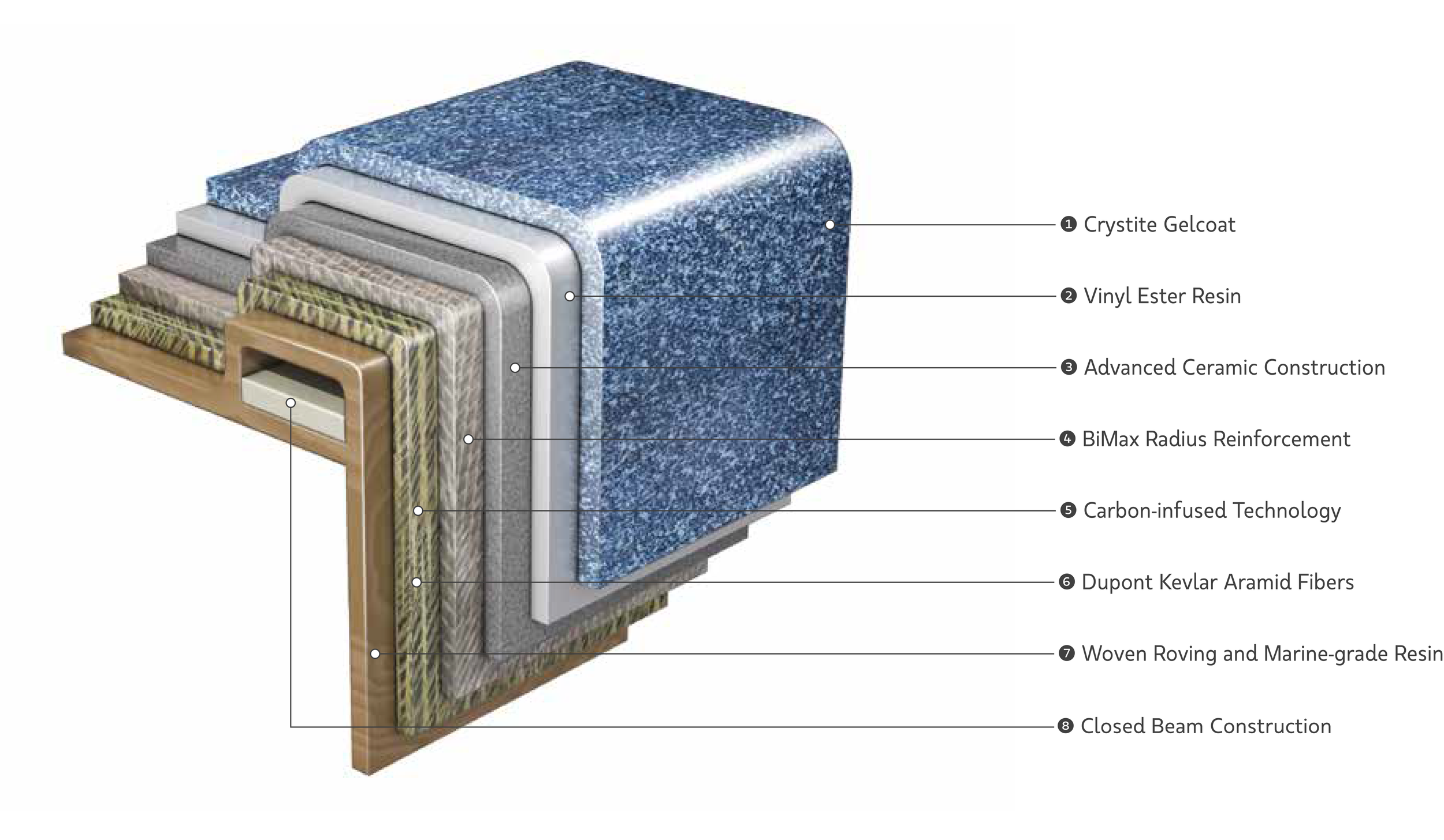

At its core, a fiberglass Jeep body is a non-metallic, composite recreation of a Jeep’s original steel tub and external body panels. Manufacturers create these bodies by laying sheets of fiberglass mat or cloth, saturated with a thermosetting resin (typically polyester or vinylester), into precise molds taken from original Jeep bodies. Once cured, the resin hardens, creating a rigid, monolithic structure that faithfully replicates the dimensions and contours of the classic Jeep.

Unlike steel, which is prone to oxidation when exposed to moisture and oxygen, fiberglass is inert. It doesn’t rust, corrode, or degrade in the same manner. This inherent resistance makes it an ideal material for vehicles that are frequently exposed to harsh weather, mud, saltwater, or simply the passage of time. Fiberglass bodies are typically lighter than their steel counterparts, which can translate into improved fuel economy (minimal as it might be for a Jeep!), better power-to-weight ratio, and potentially enhanced off-road performance due to a lower center of gravity and reduced overall vehicle weight. They also offer a degree of flexibility, making them more resistant to minor dents and dings than rigid steel.

Why Choose Fiberglass? Benefits Galore

The decision to opt for a fiberglass Jeep body over traditional steel is often driven by a compelling list of advantages:

- Absolute Rust Immunity: This is arguably the biggest selling point. With fiberglass, the constant battle against rust becomes a thing of the past. No more worrying about bubbling paint, structural integrity compromise, or extensive patch panel work. This dramatically reduces long-term maintenance and preserves the vehicle’s aesthetic and structural integrity indefinitely.

- Lightweight Advantage: Fiberglass bodies are significantly lighter than steel. A typical fiberglass CJ-7 tub might weigh 200-300 lbs less than its steel equivalent. This weight reduction can lead to better acceleration, improved braking, and reduced strain on suspension components, axles, and the engine. For serious off-roaders, a lighter vehicle can also mean less bogging down in soft terrain.

- Durability and Resilience: While often perceived as fragile, cured fiberglass is remarkably strong and resilient. It can absorb impacts better than steel in some scenarios, flexing slightly rather than denting or creasing. In the event of damage, fiberglass is often easier to repair than steel, as it can be patched and re-sanded seamlessly, often by a skilled DIY enthusiast.

- Ease of Customization: Working with fiberglass is generally easier for custom modifications than welding steel. Cutting, sanding, and bonding new sections or accessories is straightforward, allowing for easier integration of custom dashboards, roll cage mounts, or unique body modifications.

- Cost-Effectiveness (Long Term): While the initial purchase price of a fiberglass tub might seem comparable to or even slightly higher than a used steel tub, the long-term savings are substantial. You eliminate the immense costs associated with sandblasting, rust repair, welding, body filler, and extensive prep work required for a rusty steel body. This makes fiberglass a very attractive option for a complete, ground-up restoration.

- Perfect Fitment: Reputable manufacturers use precision molds, ensuring that their fiberglass bodies are dimensionally accurate and fit existing Jeep chassis, doors, and tops with minimal modification. This makes the assembly process smoother and less frustrating.

.jpg)

Types of Fiberglass Jeep Bodies Available

The market for fiberglass Jeep bodies is robust, catering to a wide range of models and restoration needs. You’ll primarily find full body tubs, but individual panels are also available:

- Full Tubs: These are the most common and comprehensive offering, providing the entire passenger compartment from the firewall back to the tailgate opening.

- CJ Series (CJ-2A, CJ-3A, CJ-3B, CJ-5, CJ-6, CJ-7, CJ-8 Scrambler): These are by far the most popular models for fiberglass replacement, given their age and susceptibility to rust. You can find highly accurate reproductions for almost every CJ variant.

- YJ Wrangler (1987-1995): While newer than CJs, YJ Wranglers are still old enough to suffer from significant rust issues, especially in salty climates. Fiberglass YJ tubs are readily available.

- TJ Wrangler (1997-2006): Even TJs, particularly those from the earlier years, can develop rust in key areas. Fiberglass TJ tubs offer a complete rust-free solution.

- Individual Panels: For those who only need specific sections or want to mix and match, individual fiberglass components are also sold:

- Fenders (front and rear)

- Hoods

- Grille shells

- Tailgates

- Dashboards

- Floor sections

When considering types, it’s crucial to confirm compatibility with your specific Jeep model year and existing chassis. While most are designed for direct bolt-on, minor variations can occur between different manufacturers.

Key Considerations Before Buying

Purchasing a fiberglass Jeep body is a significant investment that requires careful consideration:

- Manufacturer Reputation and Quality: Not all fiberglass bodies are created equal. Research manufacturers thoroughly. Look for companies with a long track record, positive customer reviews, and a reputation for using high-quality resins and robust construction methods (e.g., proper reinforcement in stress areas, uniform thickness).

- Fitment and Accuracy: Inquire about the precision of the molds used. Does the body accurately replicate original dimensions? Will your existing doors, windshield frame, and hardtop or soft top fit without extensive modification? Some manufacturers offer "test fits" or guarantee fitment.

- Included Components: Understand what’s included in the price. Does it come with the firewall, inner fender wells, dash panel, tailgate opening, and floor supports? Are provisions for body mounts, seat belts, and wiring already molded in, or will you need to drill/fabricate them?

- Shipping and Handling: Fiberglass bodies are large and require specialized freight shipping. Obtain clear quotes for shipping costs and understand the delivery process. Inspect the body thoroughly upon arrival for any shipping damage before signing off.

- Legal Aspects (VIN Transfer): This is a critical point. In most jurisdictions, the Vehicle Identification Number (VIN) is stamped on the original steel body (firewall or inner fender). When replacing the body, you cannot simply transfer the old VIN plate to the new fiberglass body. You will typically need to retain the section of the original steel body containing the VIN, or follow specific state-by-state procedures for title and VIN verification. Consult your local Department of Motor Vehicles (DMV) or equivalent agency for exact requirements before purchase. Some fiberglass bodies come with a Manufacturer’s Statement of Origin (MSO) which can assist in titling a "new" vehicle if you’re building from scratch.

- Paint and Finish Prep: Fiberglass bodies come in a gel coat finish, which is often a basic white or gray. This gel coat is a protective layer but is not the final paint finish. It will require proper sanding, priming, and painting just like any other automotive body part.

The Installation Process: A DIYer’s Guide (or When to Seek Professional Help)

Installing a fiberglass Jeep body is a significant project, but it’s well within the capabilities of an experienced DIY mechanic with the right tools and patience.

- Donor Vehicle Preparation: The process begins with stripping down your donor Jeep. This involves removing the old body, all interior components, wiring harnesses, fuel lines, brake lines, and anything else attached to the tub. The chassis should be thoroughly inspected, cleaned, repaired (if necessary), and painted to provide a solid foundation.

- Body Mounts: Fiberglass bodies typically utilize the original body mount locations on the frame. Ensure these are clean and in good condition. New body mount bushings (often polyurethane) are highly recommended.

- Test Fit and Alignment: Before final bolting, perform a thorough test fit. Place the new fiberglass tub onto the chassis and check alignment with the frame, existing doors (if reusing), and the windshield frame. Make any minor adjustments or shimming as needed.

- Component Transfer: This is where the bulk of the work lies. You’ll transfer all your original or new components to the fiberglass tub: wiring harness, steering column, pedal assembly, dash components, seats, roll bar, fuel tank, and brake lines. Take your time, label everything, and refer to service manuals.

- Drilling and Reinforcement: While some fiberglass bodies come with pre-drilled holes, many require drilling for body mounts, seat belts, and accessories. Always reinforce bolt-through points with backing plates or large washers to distribute stress and prevent cracking.

- Painting: Once mounted and all components are test-fitted, the body will need to be prepared for paint. This involves sanding the gel coat, applying a high-build primer, and then the final paint color. Professional painting is often recommended for a show-quality finish.

- Final Assembly: Reinstall doors, hood, fenders, grille, and any other exterior panels. Connect lights, trim, and interior finishes.

For those less confident in their mechanical abilities, or lacking the necessary tools and space, professional shops specializing in Jeep restorations or custom fabrication can handle the installation, ensuring a flawless result.

Maintenance and Longevity

One of the greatest advantages of fiberglass is its low maintenance.

- Cleaning: Regular washing with automotive soap and water is sufficient. Avoid abrasive cleaners or harsh chemicals.

- Minor Repairs: Small chips or cracks in the gel coat can be easily repaired with readily available fiberglass repair kits, often color-matched to the original gel coat or prepared for paint. More significant damage can be patched and blended seamlessly.

- Paint Care: Treat the painted fiberglass just like you would any other automotive paint. Waxing and polishing will protect the clear coat and maintain its luster.

With proper care, a fiberglass Jeep body will outlast the chassis it sits on, providing decades of rust-free enjoyment.

Finding Fiberglass Jeep Bodies For Sale

Several avenues exist for purchasing fiberglass Jeep bodies:

- Specialized Manufacturers: Companies like Aqualu, Collins Bros. Jeep (Jeep to the Rescue), and other niche fabricators specialize in fiberglass reproductions for various Jeep models. These are often the best sources for quality and fitment.

- Online Marketplaces: Websites like eBay, Craigslist, and Facebook Marketplace occasionally feature used or new fiberglass bodies from private sellers or smaller fabricators. Exercise caution and thoroughly vet sellers.

- Jeep Forums and Classifieds: Dedicated Jeep enthusiast forums often have classified sections where members buy, sell, and trade parts, including fiberglass bodies. These communities can also provide valuable insights and recommendations.

- Custom Fabrication Shops: Some custom shops might build fiberglass bodies to order or have connections to manufacturers.

Potential Challenges and Solutions

While fiberglass offers numerous benefits, it’s not without its potential quirks:

- Fitment Variations: Even with good molds, slight variations can occur between manufacturers or even within production runs. Be prepared for minor shimming or adjustments during installation.

- Quality Discrepancies: As mentioned, quality varies. Avoid "bargain" bodies that might use cheaper resins, have inconsistent thickness, or lack proper internal reinforcement, as these can lead to cracking or premature failure.

- Painting Difficulties: Gel coat provides a good base, but fiberglass can be prone to "print-through" (where the pattern of the underlying fiberglass mat becomes visible through the paint over time) if not properly primed and prepped. Professional painting helps mitigate this.

- VIN Concerns: This is the most significant legal hurdle. Always understand your local DMV’s requirements for VIN transfer or new vehicle registration when replacing the body. Document everything meticulously.

Fiberglass Jeep Body Estimated Price Guide

Prices for fiberglass Jeep bodies vary significantly based on the Jeep model, the manufacturer’s reputation, the completeness of the body (full tub vs. panels), and included features. The following table provides estimated price ranges for common fiberglass Jeep bodies, excluding shipping and paint.

| Jeep Model | Body Type | Key Features | Estimated Price Range (USD) | Notes/Compatibility |

|---|---|---|---|---|

| CJ-2A/CJ-3A/CJ-3B | Full Tub | High-strength composite, rust-proof, often includes firewall, inner fenders, dash. Designed for original frame. | $3,500 – $5,500 | Ideal for early "flatfender" restorations. May require specific year-matching details. |

| CJ-5 (1955-1983) | Full Tub | Seamless, one-piece construction, reinforced mounting points, accepts original doors, windshield, top. | $4,000 – $6,000 | Fits various CJ-5 frame lengths. Check compatibility with specific year’s minor body differences. |

| CJ-7 (1976-1986) | Full Tub | Most popular fiberglass body. Rust-proof, lightweight, includes firewall, dash, floor, tailgate opening. Designed for factory mounting. | $4,500 – $7,000 | Direct replacement for steel CJ-7 tubs. Wide availability from multiple manufacturers. |

| CJ-8 Scrambler | Full Tub | Extended wheelbase version of the CJ-7 tub, replicating the Scrambler’s unique utility bed. Includes firewall, dash, reinforced. | $5,500 – $8,000 | Less common, often made to order. Essential for faithful Scrambler restoration or custom builds. |

| YJ Wrangler (1987-95) | Full Tub | Replica of square-headlight Wrangler tub. Rust-proof, often includes floor, inner fenders, firewall. | $4,500 – $6,500 | Designed for YJ chassis. Some minor trim/accessory differences might exist with specific year models. |

| TJ Wrangler (1997-06) | Full Tub | Reproduction of the coil-sprung TJ tub. Offers modern rust protection for a newer classic. Includes floor, firewall, inner fenders. | $5,000 – $7,500 | Fits TJ/LJ frames. Ensures a solid foundation for more modern Jeep builds. |

| Universal Fenders | Front Fenders | Lightweight, durable, often wider for larger tires. Sold as pairs. | $300 – $800 (per pair) | Can be used to replace rusty steel fenders or for custom builds. Verify mounting points for specific models. |

| Universal Hoods | Hood | Smooth finish, often lighter than steel. | $300 – $700 | Check compatibility with specific grille shells and hinges. |

| Various Models | Grille Shells | Exact replicas of factory grille designs. | $200 – $400 | Specific to each model (CJ, YJ, TJ). |

| Various Models | Tailgates | Rust-proof replacement for factory tailgate. | $200 – $500 | Can be ordered with or without spare tire carrier provisions. |

Note: Prices are estimates and subject to change based on market conditions, manufacturer, material costs, and specific features. Always request a direct quote.

Frequently Asked Questions (FAQ) about Fiberglass Jeep Bodies

Q1: Are fiberglass Jeep bodies as strong as steel?

A1: While steel has a higher tensile strength, fiberglass bodies are incredibly durable and strong, especially when properly reinforced. They are more resistant to minor impacts and rust, which can severely weaken steel over time. For off-roading, a well-built fiberglass body can be highly resilient.

Q2: Can I paint a fiberglass Jeep body?

A2: Absolutely! Fiberglass bodies come with a gel coat finish, which is designed to be sanded, primed, and painted just like any other automotive surface. For the best results, professional automotive painting is recommended.

Q3: Do fiberglass bodies weigh less than steel?

A3: Yes, significantly. A full fiberglass Jeep tub can be 200-300 lbs lighter than its steel counterpart, offering benefits in performance, fuel economy, and reduced stress on drivetrain components.

Q4: How do I handle the VIN when replacing my steel body with fiberglass?

A4: This is crucial and varies by state/country. Generally, you cannot simply transfer the VIN tag. You may need to retain the section of the original frame or body that contains the VIN, or follow a specific process for vehicle re-registration or obtaining a new VIN through your local Department of Motor Vehicles (DMV). Always consult your local regulations before starting the project.

Q5: Is installation difficult for a DIYer?

A5: Installing a fiberglass body is a major undertaking, but it’s achievable for an experienced DIY mechanic with good tools and patience. It involves stripping the old body, preparing the chassis, transferring components, and meticulous alignment. If you’re not comfortable with extensive mechanical work, professional installation is recommended.

Q6: Are fiberglass bodies prone to cracking?

A6: Quality fiberglass bodies from reputable manufacturers are designed with reinforcements in stress areas to prevent cracking. Using proper body mounts and avoiding excessive flex in the chassis will also help. Minor cracks, if they occur, are generally easy to repair.

Q7: Will my original Jeep parts (doors, windshield, top) fit on a fiberglass body?

A7: Reputable fiberglass body manufacturers strive for exact reproductions, meaning original parts like doors, windshield frames, soft tops, and hardtops should fit correctly. Always confirm compatibility with the specific manufacturer before purchasing.

Conclusion

Fiberglass Jeep bodies for sale represent a game-changer for enthusiasts looking to restore, customize, or simply preserve their beloved Jeeps for generations to come. By eliminating the perpetual battle against rust, offering significant weight savings, and providing a durable, easily modifiable platform, fiberglass offers a compelling alternative to traditional steel. While the initial investment and the complexity of installation require careful planning, the long-term benefits in terms of reduced maintenance, enhanced longevity, and the sheer joy of owning a truly rust-free classic Jeep make it an incredibly worthwhile endeavor. With thorough research, a reputable manufacturer, and a clear understanding of the installation process, your dream of a perpetually rugged, perpetually pristine Jeep is well within reach.