Jeep Dana 44 Front Axle For Sale: Your Ultimate Guide to an Off-Road Powerhouse

Jeep Dana 44 Front Axle For Sale: Your Ultimate Guide to an Off-Road Powerhouse jeeps.truckstrend.com

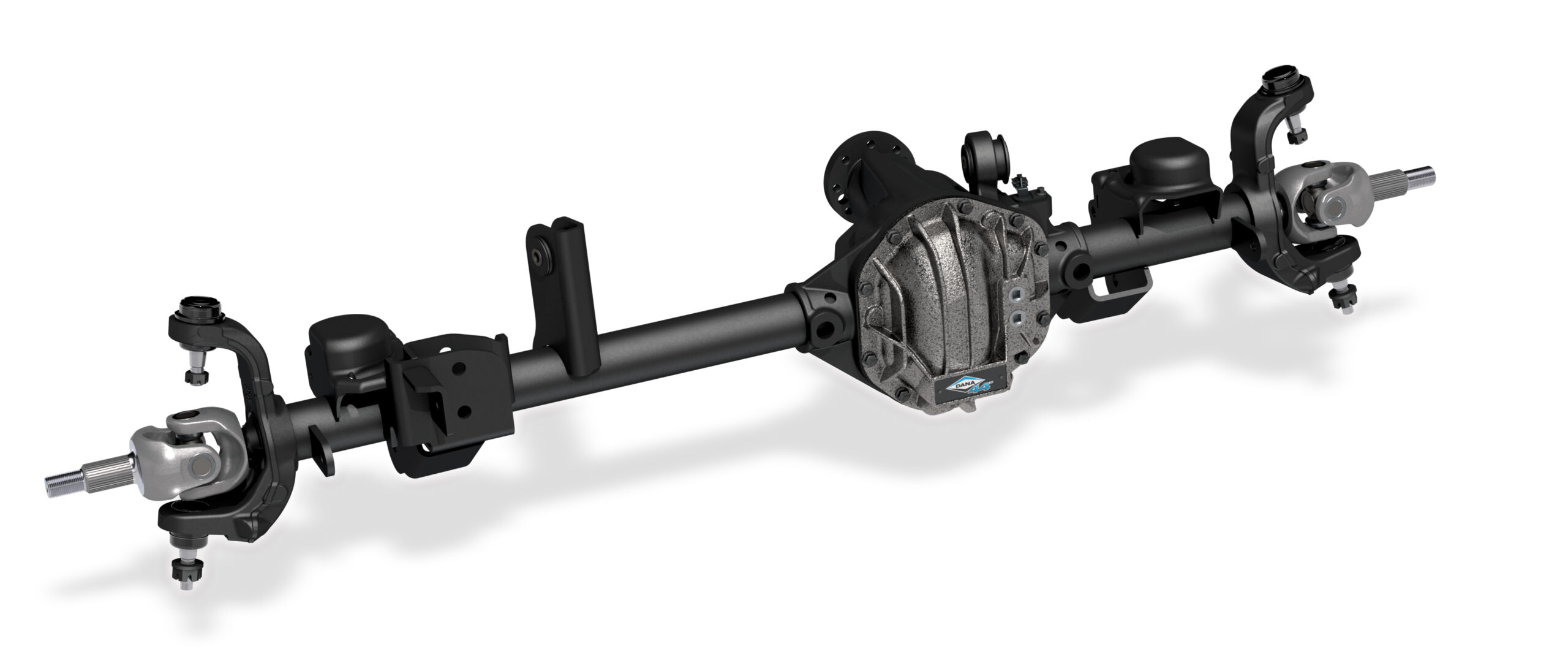

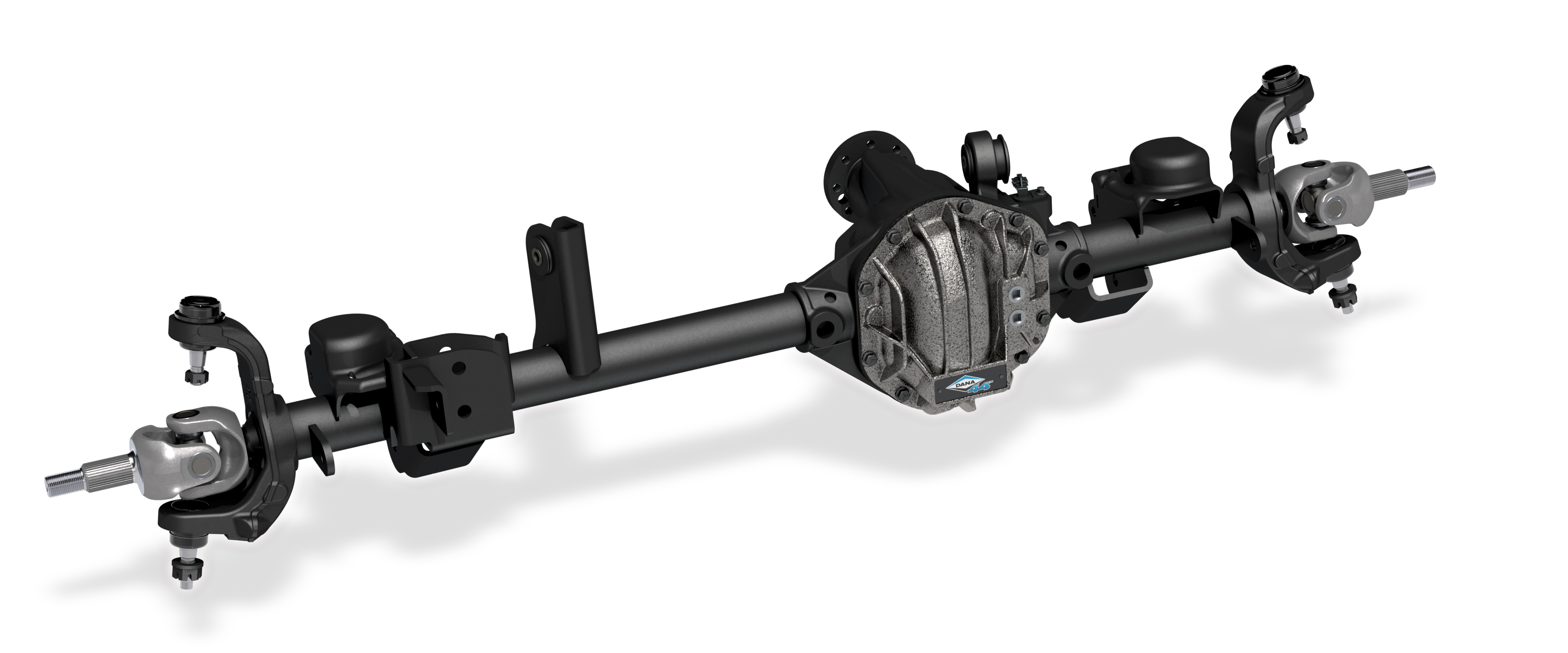

For any serious Jeep enthusiast, the pursuit of superior off-road capability often leads to one critical component: the axle. While stock axles serve their purpose, the desire for greater strength, durability, and performance inevitably points towards an upgrade. Among the pantheon of revered aftermarket and OEM components, the Jeep Dana 44 Front Axle For Sale stands out as a legendary choice. This comprehensive guide will delve into everything you need to know about acquiring, understanding, and leveraging this robust piece of engineering to transform your Jeep into an unstoppable off-road machine.

Introduction: The Legendary Dana 44 Front Axle

Jeep Dana 44 Front Axle For Sale: Your Ultimate Guide to an Off-Road Powerhouse

The Dana 44 front axle is more than just a collection of gears and steel; it’s a statement of intent for serious off-roaders. Renowned for its significant strength upgrade over the more common Dana 30 front axle found in many stock Jeeps, the Dana 44 boasts larger axle tubes, a more robust ring and pinion gear, and generally higher spline count axle shafts. This translates directly to enhanced durability, reduced risk of breakage on challenging trails, and the ability to confidently run larger tires.

Whether you’re looking to replace a damaged stock axle, prepare your rig for extreme rock crawling, or simply seeking peace of mind on gnarly trails, finding a Jeep Dana 44 Front Axle For Sale is often the first step in a significant driveline upgrade. Its popularity stems from a perfect blend of strength, availability, and a vast aftermarket support system, making it an ideal choice for a wide range of Jeep models and off-road applications.

Why the Dana 44? Understanding Its Unmatched Appeal

The allure of the Dana 44 isn’t just hype; it’s rooted in tangible engineering advantages. Compared to its smaller sibling, the Dana 30, the Dana 44 offers:

- Increased Strength: The Dana 44 features a larger ring gear (8.5 inches vs. 7.12 inches for the Dana 30) and a larger pinion gear, allowing for greater torque handling and resistance to stripping. The axle tubes are also typically thicker, providing better resistance to bending.

- Durability for Larger Tires: While a Dana 30 can handle up to 33-inch tires with some upgrades, the Dana 44 is much more comfortable with 35-inch tires and, with further modifications, can reliably handle 37s or even 40s. This is crucial for serious off-roaders who need maximum ground clearance and traction.

- Vast Aftermarket Support: The Dana 44 has been a staple in the off-road community for decades, leading to an enormous selection of aftermarket parts. From lockers and limited-slip differentials to chromoly axle shafts, heavy-duty differential covers, and trussing kits, nearly every component can be upgraded or replaced to meet specific needs.

- Common OEM Application: Many higher trim level Jeeps (like the Rubicon) came standard with Dana 44s, meaning there’s a good supply of used OEM units available, which can be a cost-effective starting point for an upgrade.

This combination of inherent strength and widespread support makes the Dana 44 a go-to choice for anyone serious about pushing their Jeep’s limits.

Identifying the Right Dana 44 for Your Jeep

Not all Dana 44s are created equal. When searching for a Jeep Dana 44 Front Axle For Sale, it’s crucial to understand the variations to ensure compatibility and suitability for your specific build.

-

Vehicle Compatibility (Jeep Model):

- TJ/LJ Wranglers (1997-2006): These typically used low-pinion Dana 30s or low-pinion Dana 44s in the rear (Rubicon models had front and rear Dana 44s). A front Dana 44 swap for a TJ usually involves a custom-built axle or adapting one from another vehicle (like an XJ or Wagoneer) with significant fabrication.

- JK Wranglers (2007-2018): Rubicon JKs came with Dana 44s front and rear. Non-Rubicons had Dana 30 fronts. JK Dana 44s are wider than TJ axles and feature different mounting points.

- JL Wranglers (2018+): Similar to JKs, Rubicon JLs have wider, next-generation Dana 44s. Non-Rubicons have Dana 30 fronts. JL axles are even wider and have different mounting points than JKs.

- XJ Cherokees (1984-2001) & MJ Comanches (1986-1992): Some XJs came with low-pinion Dana 30s. Wagoneer XJs (earlier models) sometimes had a low-pinion Dana 44 front, which is a popular swap for TJs due to its narrower width.

- YJ Wranglers (1987-1995) & CJ Models (1976-1986): These generally had Dana 30 fronts or narrow track Dana 44s. Finding a direct bolt-in Dana 44 can be challenging, often requiring custom builds or adapting other axles.

-

High-Pinion vs. Low-Pinion:

- High-Pinion (HP44): The pinion gear enters the differential from above the centerline of the ring gear. This design offers better driveshaft angles, especially on lifted Jeeps, and more ground clearance under the driveshaft. It also loads the "drive" side of the ring gear teeth, which are stronger, making it inherently stronger than a low-pinion under forward acceleration. Found in some Ford F-150s, Broncos, and older Dodge trucks.

- Low-Pinion (LP44): The pinion gear enters below the centerline. Less ideal driveshaft angles for lifted vehicles and loads the "coast" side of the ring gear teeth during forward motion, which is weaker. Most stock Jeep Dana 44s (excluding Rubicon JKs/JLS) are low-pinion.

-

Axle Width: Crucial for tire clearance, turning radius, and overall stance. Common widths include narrow track (CJ, XJ Wagoneer), full width (JK, JL, Ford/Dodge trucks), and custom widths. Ensure the width matches your fender flares and desired look.

-

Gearing: The internal gear ratio (e.g., 3.73, 4.10, 4.56, 4.88) must match the rear axle ratio precisely. If you’re only replacing the front, you’ll need to find a Dana 44 with the same ratio as your existing rear axle, or plan to re-gear both front and rear.

-

Locker/Limited Slip: Some Dana 44s come equipped with a locker (like the Tru-Lok in Rubicon models) or a limited-slip differential. This is a significant added value, as these components can be expensive to install separately.

Where to Find a Dana 44 Front Axle For Sale

The hunt for a Dana 44 can take you to several places, each with its own pros and cons:

- New Aftermarket Axles:

- Pros: Brand new, stronger than OEM, often come with enhanced features (thicker tubes, forged knuckles, specific gearing/lockers), bolt-in ready for specific Jeep models. Brands like Dynatrac, Currie Enterprises, G2 Axle & Gear, and TeraFlex offer complete, robust solutions.

- Cons: Most expensive option.

- Used OEM Axles (Junkyards/Salvage Yards):

- Pros: Cost-effective, good for budget builds. Can be sourced from Jeep Rubicons (JK/JL) or older trucks (Ford F-150/Bronco HP44s).

- Cons: Condition is unknown, may require rebuilding (bearings, seals, ball joints), may need significant fabrication to fit (especially truck axles), potential for hidden damage.

- Online Marketplaces & Forums:

- Pros: Wide reach, often connect directly with other enthusiasts. Check Facebook Marketplace, Craigslist, dedicated Jeep forums (e.g., JeepForum.com, JK-Forum.com), and off-road classifieds.

- Cons: "Buyer beware" – inspect thoroughly, can be subject to scams, shipping can be expensive.

- Specialized Off-Road Shops:

- Pros: Can offer new, used, or rebuilt axles. Expertise on hand, often provide installation services.

- Cons: Prices may be higher than private sellers.

What to Inspect When Buying a Used Dana 44

Buying a used axle requires a careful eye. Don’t rush the purchase; a thorough inspection can save you significant time and money down the line.

- Housing Integrity: Look for bends, cracks, or significant rust. Pay attention to the axle tubes – any signs of bending or previous repair (welds) are red flags.

- Differential Housing: Check for cracks, especially around the welds where the tubes meet the center section. Look for impact damage to the diff cover.

- Axle Shafts: If included, check for straightness, especially if visible. Inspect the splines at both ends for twisting or wear.

- Gears: While you can’t fully inspect the gear pattern without opening the differential, check for excessive play (backlash) in the pinion or carrier. Any grinding noises when rotating indicate issues. Ask for history of maintenance or gear changes.

- Bearings and Seals: Check for leaks around the differential cover, pinion seal, and axle tube seals. Excessive play in the wheel bearings or pinion bearing indicates wear.

- Knuckles and Ball Joints: Inspect the ball joints for excessive play by lifting the tire and trying to wiggle it at 12 and 6 o’clock. Check for cracks in the knuckles, especially on high-stress areas.

- Mounting Points: Ensure all mounting brackets (control arm mounts, coil spring perches, shock mounts, track bar mount) are present, intact, and not severely bent or cracked. If buying for a specific swap, ensure these match or can be easily modified.

- Brakes: If the axle comes with brakes, inspect the rotors, calipers, and pads for wear. Factor in replacement costs if they are worn out.

Installation Considerations and Potential Upgrades

Installing a Dana 44 front axle can range from a relatively straightforward bolt-in (for new aftermarket axles designed for your specific Jeep) to a complex fabrication project (for adapting a used truck axle).

- Professional vs. DIY: Unless you have advanced mechanical skills, a full set of tools (including a welder for custom mounts), and experience with driveline components, professional installation by an off-road shop is highly recommended. Improper installation can lead to dangerous failures.

- Associated Costs: Beyond the axle itself, factor in:

- Installation Labor: Significant if done by a shop.

- New Parts: Ball joints, bearings, seals, brakes, and potentially new driveshafts may be needed.

- Gearing: If the new axle’s ratio doesn’t match your rear, you’ll need to re-gear both, which is a substantial cost.

- Steering Components: Stronger tie rods and drag links are often recommended when upgrading to a Dana 44, especially with larger tires.

- Recommended Upgrades: Even a stock Dana 44 can be improved:

- Chromoly Axle Shafts: Stronger than stock, reducing the chance of breakage.

- Trussing: Welding a steel truss to the axle tubes adds significant rigidity, preventing bending.

- Heavy-Duty Differential Cover: Protects the ring and pinion from impacts.

- Hydro Assist Steering: For larger tires, this can greatly reduce steering effort and component wear.

Legal and Safety Considerations

Modifying your vehicle’s driveline has legal and safety implications. Always ensure:

- Local Regulations: Check local laws regarding vehicle modifications, especially axle width, tire size, and lift height.

- Proper Installation: Safety is paramount. Ensure all components are installed correctly, torqued to spec, and that steering and braking systems are fully functional. If unsure, consult a professional.

Practical Advice and Actionable Insights

- Set a Realistic Budget: Dana 44 swaps can quickly add up. Factor in not just the axle cost, but also shipping, rebuilding, installation, and any necessary complementary upgrades (driveshafts, steering, re-gearing).

- Do Your Research: Understand the nuances of different Dana 44 variants and which ones are best suited for your Jeep model and intended use.

- Inspect Thoroughly: For used axles, bring a knowledgeable friend or even pay a local shop for a pre-purchase inspection if possible.

- Negotiate: Don’t be afraid to haggle, especially on used axles. Point out any wear or potential issues to justify a lower price.

- Buy Complete if Possible: A complete, ready-to-bolt-in axle (even if used) often saves money and headaches compared to buying a bare housing and sourcing all internal components separately.

- Consider the Long Term: An axle upgrade is a foundational modification. Think about your future build plans (tire size, type of wheeling) when selecting your Dana 44.

Jeep Dana 44 Front Axle Estimated Price Guide

Please note: Prices are highly variable based on condition, location, specific features (gearing, locker), and market demand. These are estimated ranges.

| Axle Type/Condition | Estimated Price Range (USD) | Key Inclusions/Features | Notes |

|---|---|---|---|

| Used OEM Bare Housing | $300 – $800 | Housing only, no internals, shafts, or brakes. | Requires full rebuild. Good for custom builds where you’re adding all new components. Price varies heavily by source (junkyard vs. private seller). |

| Used OEM Complete (Stock) | $800 – $2,500 | Housing, stock gears, open differential, shafts, knuckles, brakes (may need service). | Common from wrecked Rubicons or upgrades. Condition is key. May require new ball joints, seals, and re-gearing to match your rear axle. |

| Used OEM Complete (Upgraded) | $2,000 – $4,500 | Complete with aftermarket locker/LSD, upgraded shafts, maybe diff cover. | Significant value if it matches your needs. Thorough inspection is crucial to verify upgrades and condition. |

| New Aftermarket Basic | $4,000 – $6,500 | Brand new housing, new gears, open differential, shafts, ready for bolt-in. | Stronger than OEM. Ideal for a fresh start. You’ll likely want to add a locker. |

| New Aftermarket Performance | $7,000 – $12,000+ | Brand new, heavy-duty housing, chromoly shafts, choice of locker, custom gearing, heavy-duty knuckles, trussing. | Top-tier performance for extreme off-roading. Often fully customized to your vehicle and tire size. Brands like Dynatrac, Currie. |

| Installation Labor (Estimated) | $800 – $2,000+ | Professional installation of a complete axle. | Varies by shop, complexity (custom fabrication adds cost). Does not include parts. |

| Re-gearing Service (Per Axle) | $600 – $1,000+ | Labor for setting up new ring and pinion. Parts extra. | Critical if new axle ratio doesn’t match. Always re-gear both axles simultaneously. |

Frequently Asked Questions (FAQ)

Q1: Is a Dana 44 always better than a Dana 30?

A1: For serious off-roading, yes. The Dana 44 offers significant strength advantages for larger tires and more aggressive trails. However, a Dana 30 can be adequate for light to moderate trails, especially with minor upgrades.

Q2: Can I put a Dana 44 from a different model year/vehicle into my Jeep?

A2: Often, yes, but it will likely require fabrication (welding new mounting brackets, spring perches, shock mounts) to fit correctly. Axle width, pinion type (high/low), and bolt patterns are critical considerations. This is common for XJ Cherokee or Ford F-150 Dana 44 swaps into TJ/YJ Wranglers.

Q3: What’s the difference between high-pinion and low-pinion Dana 44s?

A3: High-pinion (HP44) axles have the pinion gear entering the differential from above the centerline, offering better driveshaft angles for lifted vehicles and being inherently stronger under forward acceleration. Low-pinion (LP44) axles have the pinion entering below the centerline, which is generally weaker on the drive side and has less ideal driveshaft angles for lifted rigs.

Q4: Do I need to re-gear my rear axle if I upgrade my front Dana 44?

A4: Absolutely. Both front and rear axle gear ratios must match precisely. Running different ratios will cause severe drivetrain binding and damage, especially when engaging 4WD. If the new front Dana 44 has a different ratio than your current rear axle, you’ll need to re-gear both.

Q5: What are common issues with Dana 44 axles?

A5: While strong, Dana 44s can still experience issues. Common wear items include ball joints, unit bearings (on JK/JL axles), and axle seals. On highly abused axles, bent axle tubes, worn gear sets, or cracked housings can occur. Aftermarket chromoly shafts are a common upgrade to prevent shaft breakage.

Q6: How much does a Dana 44 installation cost?

A6: If you’re paying a professional shop, installation costs for a complete, bolt-in Dana 44 can range from $800 to $2,000+, depending on the complexity and any additional work needed (like re-gearing, driveshaft modifications, or steering upgrades).

Conclusion

The Jeep Dana 44 Front Axle For Sale represents a pivotal upgrade for any Jeep aiming for serious off-road prowess. Its inherent strength, coupled with robust aftermarket support, makes it a superior choice for handling larger tires and tackling more demanding terrain. However, the journey to acquire and install the right Dana 44 requires careful research, diligent inspection, and a clear understanding of your specific Jeep’s needs and your off-roading ambitions.

By considering the various types, inspecting used units thoroughly, and planning for associated costs and potential upgrades, you can confidently navigate the market for a Dana 44. The investment in this legendary axle will undoubtedly pay dividends in enhanced durability, unwavering performance, and the peace of mind that comes from knowing your Jeep is equipped to conquer whatever the trail throws at it. So, begin your search, gear up, and prepare to elevate your off-road experience to the next level.