Cummins 2.8 Diesel Engine For Sale Jeep Adapter: The Ultimate Guide to Your Diesel Jeep Conversion

Cummins 2.8 Diesel Engine For Sale Jeep Adapter: The Ultimate Guide to Your Diesel Jeep Conversion jeeps.truckstrend.com

For decades, Jeep enthusiasts have sought the perfect blend of rugged capability and reliable power. While gasoline engines have traditionally dominated the scene, a growing movement is embracing the efficiency and torque of diesel power. At the forefront of this trend is the Cummins R2.8 Turbo Diesel engine, a compact yet potent powerplant that has become the darling of the aftermarket swap community. When paired with the right Jeep adapter, this engine transforms a standard Jeep into an off-road beast with impressive fuel economy and rock-crawling prowess.

This comprehensive guide delves into everything you need to know about the Cummins 2.8 Diesel Engine for sale and the essential Jeep adapter kits that make this dream swap a reality. Whether you’re a seasoned mechanic or a curious enthusiast, prepare to unlock the full potential of your Jeep.

Cummins 2.8 Diesel Engine For Sale Jeep Adapter: The Ultimate Guide to Your Diesel Jeep Conversion

The Cummins R2.8 Turbo Diesel: A Powerhouse for Jeeps

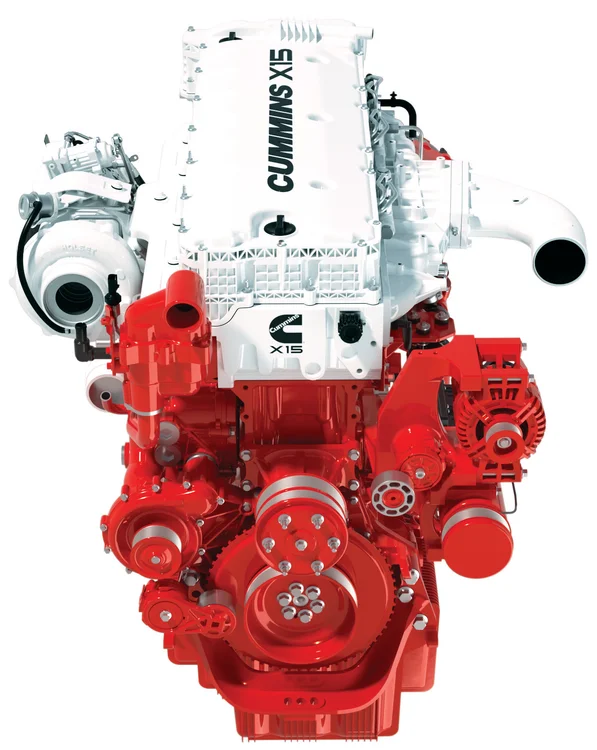

The Cummins R2.8 Turbo Diesel is not just any diesel engine; it’s a "crate engine" specifically designed by Cummins for the aftermarket and engine swap market. Launched as part of their "Repower" program, the R2.8 offers a modern, lightweight, and compact solution for those looking to upgrade their vehicle’s powertrain.

Key Specifications & Why It’s Ideal for Jeeps:

- Displacement: 2.8 Liters (171 cubic inches)

- Configuration: Inline 4-cylinder, DOHC

- Horsepower: Approximately 161 hp @ 3600 rpm (stock tune)

- Torque: Approximately 310 lb-ft @ 1800 rpm (stock tune)

- Weight: Around 500 lbs (dry)

- Fuel System: Common rail direct injection

- Emissions: Generally EPA compliant as a crate engine for off-road and pre-emissions vehicles.

What makes the R2.8 particularly attractive for Jeeps is its impressive low-end torque. That 310 lb-ft of torque comes in at a remarkably low 1800 rpm, which is precisely what you need for navigating challenging trails, crawling over rocks, or effortlessly pulling a trailer. Its compact size means it fits relatively well into most Jeep engine bays (YJ, TJ, JK, JL, CJ), and its lighter weight compared to some larger V8 swaps helps maintain a balanced center of gravity. Furthermore, Cummins’ legendary reliability and the potential for significant fuel economy improvements over stock gasoline engines make it an incredibly compelling choice.

Understanding the "Jeep Adapter" – The Key to Seamless Integration

The "Jeep adapter" is the linchpin of any successful Cummins R2.8 swap. Since the R2.8 is a universal crate engine, it doesn’t come with a transmission ready to bolt into a Jeep. This is where specialized adapter kits come into play. These kits are meticulously engineered to mate the Cummins R2.8’s bellhousing pattern to various Jeep manual and automatic transmissions.

Components of a Typical Jeep Adapter Kit:

- Bellhousing Adapter Plate: This is the core component, a precision-machined plate that bridges the bolt pattern difference between the Cummins engine and the Jeep transmission.

- Flywheel/Flexplate: A custom-designed flywheel (for manual transmissions) or flexplate (for automatics) that bolts to the Cummins crankshaft and accommodates the Jeep transmission’s torque converter or clutch.

- Clutch Kit (for Manual Transmissions): Includes a pressure plate, clutch disc, and release bearing specifically designed to handle the Cummins’ torque and fit the Jeep transmission input shaft.

- Pilot Bearing/Bushing: Ensures proper alignment and support for the transmission input shaft in manual applications.

- Starter Relocation Bracket: Often required as the Cummins starter location might interfere with the Jeep transmission or frame.

- Hardware: All necessary bolts, nuts, and washers for installation.

Key Adapter Manufacturers:

Several reputable companies specialize in these adapter kits, each offering solutions for different Jeep models and transmissions:

- Quick Draw Brand (QDB): Widely recognized for their comprehensive kits, often including engine mounts, accessory drives, and complete wiring solutions.

- Advance Adapters: A long-standing name in the engine swap industry, offering a range of adapter plates for various engine and transmission combinations.

- AX-R Innovations: Another player providing quality adapter solutions.

Choosing the Right Adapter:

The most crucial step is identifying your specific Jeep transmission. Common Jeep transmissions targeted by R2.8 adapters include:

- Manual: AX-15 (YJ, TJ), NV3550 (TJ), NSG370 (TJ, JK), BA-10/5 (older YJ – usually swapped out)

- Automatic: 42RLE (TJ, JK), AW4 (XJ, MJ), 4L60E (often swapped in), 727, 999, etc.

Selecting the correct adapter ensures proper fitment, alignment, and reliable operation of your new diesel drivetrain.

Benefits of a Cummins R2.8 Jeep Swap

The allure of the Cummins R2.8 in a Jeep extends beyond just raw power. The benefits are multifaceted, making it a highly rewarding modification:

- Superior Fuel Economy: Diesel engines are inherently more efficient than gasoline engines. Owners often report significantly improved MPGs, sometimes in the high 20s or even low 30s, depending on the Jeep model, gearing, and driving style. This translates to extended range on trails and fewer stops at the pump.

- Unmatched Low-End Torque: This is the R2.8’s superpower for a Jeep. The abundant torque at low RPMs makes crawling over obstacles effortless, reduces the need for constant gear changes, and greatly enhances towing capabilities.

- Cummins Reliability & Longevity: Cummins engines are renowned for their durability and long service life. The R2.8, with its relatively simple design, continues this legacy, promising years of dependable service.

- Simplicity & Maintainability: Compared to modern, highly electronic diesel engines, the R2.8 is relatively straightforward. This makes it easier to diagnose and repair, especially for the DIY enthusiast.

- Increased Range & Reduced Fuel Stops: Better fuel economy directly translates to a longer range, a significant advantage for overlanding and extended off-grid adventures.

- Cool Factor & Resale Value: A diesel-swapped Jeep is unique and highly desirable in the enthusiast market, potentially increasing its resale value.

The Swap Process: What to Expect

Undertaking a Cummins R2.8 swap is a significant project that requires careful planning and execution. Here’s an overview of the typical stages:

- Planning & Research: Determine your budget, assess your mechanical skill level, and research state-specific emissions and legality requirements. Decide which Jeep model and transmission you’ll use.

- Engine & Adapter Acquisition: Purchase your Cummins R2.8 crate engine (often sold as a complete "Repower" kit with ECU, wiring, and accessories) and the appropriate Jeep adapter kit for your transmission.

- Engine Removal & Bay Prep: Remove your existing engine, clean the engine bay, and prepare it for the new powerplant.

- Transmission Preparation: If reusing your existing transmission, inspect it thoroughly and replace any worn components.

- Engine & Transmission Mating: Install the adapter plate, flywheel/flexplate, and clutch (if manual) to the Cummins engine, then carefully mate it to your Jeep transmission.

- Engine Mounting: Install the engine and transmission assembly into the Jeep using custom or aftermarket engine mounts designed for the R2.8 swap. Ensure proper clearance for oil pan, exhaust, and accessories.

- Cooling System Integration: Install an upgraded radiator and intercooler (essential for turbo-diesel performance). Run new coolant lines.

- Fuel System Modification: Replace or modify your fuel tank for diesel compatibility, install a lift pump, and run new fuel lines.

- Exhaust System Fabrication: Custom exhaust work will be required to connect the Cummins turbo to your desired exhaust routing.

- Electrical & Gauges: Integrate the Cummins wiring harness with your Jeep’s electrical system. This involves connecting power, ground, and adapting signals for your gauges (tachometer, oil pressure, water temp, etc.).

- Drivetrain Adjustments: Depending on the new engine and transmission length, driveshaft modifications (length, angle) may be necessary. Consider upgrading axles or differentials if your existing ones are not robust enough for the increased torque.

- Final Checks & First Start: Double-check all connections, fill fluids, bleed the fuel system, and perform the exciting first start!

- Tuning & Break-in: Follow Cummins’ recommendations for engine break-in and consider a custom tune for optimal performance and efficiency.

Important Considerations & Potential Challenges

While the benefits are numerous, it’s vital to be aware of the challenges and considerations involved in a Cummins R2.8 swap:

- Cost: This is not a budget swap. The engine, adapter, and all supporting modifications can add up quickly. Factor in unexpected costs.

- Skill Level Required: A successful swap demands a good understanding of automotive mechanics, electrical systems, and fabrication. If you’re not comfortable with complex projects, consider professional installation.

- Noise & Vibration: It’s a diesel engine; expect more noise and vibration than a gasoline engine. While the R2.8 is relatively refined for a diesel, it will still be noticeable.

- Weight Distribution: While lighter than some V8 diesels, the R2.8 is still heavier than many stock Jeep engines, which can affect front suspension sag. Upgraded springs and shocks may be necessary.

- Emissions Compliance: This is perhaps the most critical hurdle. While the R2.8 is sold as an EPA-compliant crate engine, vehicle-specific emissions laws vary widely by state. Research your local regulations thoroughly before committing. Some states may require an engine from the same model year or newer, and some have strict inspection rules.

- Aftermarket Support: While growing, it’s still a niche market compared to traditional gasoline engine swaps.

- Resale Value: While often positive, a highly modified vehicle may appeal to a smaller market segment.

Practical Advice & Actionable Insights

- Plan Meticulously: Create a detailed budget and a step-by-step plan. Identify all necessary components and tools beforehand.

- Buy Complete Kits: Whenever possible, opt for complete swap kits from reputable manufacturers (like Quick Draw Brand) that include the engine, adapter, mounts, and wiring. This minimizes compatibility headaches.

- Research, Research, Research: Join online forums (e.g., Pirate4x4, Jeep forum diesel sections), watch YouTube build series, and read every build thread you can find. Learn from others’ successes and mistakes.

- Budget for the Unexpected: Always set aside an extra 15-20% of your budget for unforeseen costs, such as broken bolts, specialized tools, or unexpected fabrication.

- Consider Professional Help: If you lack the time, tools, or expertise, don’t hesitate to consult or hire a professional shop specializing in engine swaps. It might save you headaches and costly errors in the long run.

- Don’t Skimp on Supporting Systems: Ensure your cooling, fuel, and electrical systems are adequately sized and properly installed to handle the diesel engine’s demands.

Estimated Pricing for Cummins R2.8 Jeep Swap Components

Please note that these are estimated prices and can vary significantly based on supplier, new vs. used parts, specific Jeep model, and market conditions. Installation labor costs are highly variable.

| Component Category | Description | Estimated Price Range (USD) |

|---|---|---|

| Cummins R2.8 Crate Engine | New, complete Repower kit (engine, ECU, wiring, accessories) | $9,000 – $13,000 |

| Jeep Transmission Adapter Kit | Bellhousing adapter, flywheel/flexplate, clutch, hardware | $1,500 – $2,500 |

| Engine Mounts (Specific to Jeep) | Custom or aftermarket mounts for R2.8 in your Jeep | $300 – $700 |

| Cooling System Upgrade | Radiator, intercooler, fan, hoses | $800 – $1,500 |

| Fuel System Components | Diesel fuel tank modification, lift pump, lines, filter | $400 – $1,000 |

| Exhaust System | Custom downpipe, piping, muffler | $500 – $1,500 |

| Driveshaft Modifications | Shortening/lengthening, new U-joints | $300 – $800 |

| Miscellaneous & Consumables | Fluids, clamps, wiring, fasteners, shop supplies, small tools | $500 – $1,500 |

| Professional Installation Labor | (If not DIY) | $3,000 – $8,000+ |

| TOTAL ESTIMATED SWAP COST | (DIY) | $13,300 – $22,500+ |

| TOTAL ESTIMATED SWAP COST | (Professionally Installed) | $16,300 – $30,500+ |

Frequently Asked Questions (FAQ)

Q1: Is the Cummins R2.8 legal in my state?

A1: This is the most complex question. While the R2.8 is sold as an EPA-compliant crate engine, vehicle-specific emissions laws vary significantly by state. Some states have strict rules about engine swaps (e.g., engine must be same year or newer than the chassis, or pass original emissions standards). It’s crucial to research your local Department of Motor Vehicles (DMV) and environmental protection agency regulations before starting. Many swaps are done on older, pre-emissions-controlled vehicles to avoid these hurdles.

Q2: Can I use my existing Jeep transmission?

A2: In many cases, yes, especially if it’s a popular manual (like AX-15, NV3550, NSG370) or a common automatic (like 42RLE). The "Jeep adapter" is designed specifically to mate the Cummins R2.8 to these transmissions. However, ensure your transmission is in good condition and capable of handling the R2.8’s increased torque. You might also need to upgrade the clutch if you have a manual.

Q3: How much power does the R2.8 make?

A3: Stock, the Cummins R2.8 Repower engine typically produces around 161 horsepower and 310 lb-ft of torque. However, with aftermarket tuning and minor modifications, these numbers can be increased, often reaching over 200 hp and 400 lb-ft of torque, significantly enhancing performance.

Q4: What kind of fuel economy can I expect after the swap?

A4: Fuel economy improvements are one of the biggest benefits. While results vary based on Jeep model, gearing, tire size, and driving style, many owners report seeing high 20s to low 30s MPG on the highway, a significant improvement over stock gasoline engines.

Q5: Is it a DIY project or do I need professional help?

A5: A Cummins R2.8 swap is a complex project requiring significant mechanical aptitude, fabrication skills, and electrical knowledge. It’s not typically recommended as a first-time DIY engine swap. If you’re not confident in your abilities, hiring a reputable shop specializing in these conversions is a wise investment.

Q6: What’s the total cost of a Cummins R2.8 swap?

A6: As outlined in the pricing table above, a DIY swap can range from $13,000 to $22,500+, while professional installation can push the total past $30,000. This includes the engine, adapter, and all necessary supporting modifications. It’s a significant investment, but one that many enthusiasts find worthwhile.

Conclusion

The Cummins 2.8 Diesel Engine For Sale Jeep Adapter represents a compelling proposition for any Jeep owner looking to redefine their vehicle’s performance. The R2.8 offers a potent blend of robust low-end torque, remarkable fuel efficiency, and Cummins’ legendary reliability, making it an ideal candidate for off-road adventures, overlanding, and even daily driving.

While the conversion is a substantial undertaking, demanding careful planning, significant investment, and often specialized skills, the rewards are undeniable. A diesel-powered Jeep delivers an unparalleled driving experience, transforming a capable vehicle into an unstoppable force on and off the pavement. With the right research, a solid plan, and a quality Jeep adapter kit, your diesel Jeep dream can become a powerful reality.