Chrysler 8.25 Jeep XJ Axle For Sale: Your Ultimate Guide to a Robust Upgrade

Chrysler 8.25 Jeep XJ Axle For Sale: Your Ultimate Guide to a Robust Upgrade jeeps.truckstrend.com

For countless Jeep Cherokee XJ enthusiasts, the quest for enhanced off-road capability often leads to one critical component: the rear axle. While the factory-equipped Dana 35 served its purpose for daily driving, its limitations quickly become apparent under the stress of larger tires, aggressive trails, and challenging obstacles. This is where the Chrysler 8.25 Jeep XJ Axle steps in as a legendary and highly sought-after upgrade.

This comprehensive guide will delve into every aspect of the Chrysler 8.25 axle, from its origins and inherent strengths to the intricacies of finding, purchasing, installing, and maintaining one for your beloved Jeep XJ. Whether you’re a seasoned off-roader or just beginning your build, understanding this robust axle is crucial for maximizing your Cherokee’s performance and durability.

Chrysler 8.25 Jeep XJ Axle For Sale: Your Ultimate Guide to a Robust Upgrade

Understanding the Chrysler 8.25 Axle: A Foundation of Strength

The Chrysler 8.25-inch rear axle, often simply referred to as the "Chryco 8.25" or "8.25," is a semi-floating, C-clip style rear axle that gained popularity among Jeep XJ owners due to its significant strength advantage over the notoriously weak Dana 35. Produced by Chrysler and found in various vehicles, its most relevant application for Jeep enthusiasts is within the XJ Cherokee itself, primarily from the late 1990s.

History and Evolution:

The Chrysler 8.25 was introduced in 1974 and saw service in a wide range of Chrysler, Dodge, and Plymouth vehicles, including trucks and vans. For the Jeep Cherokee XJ, it became an optional heavy-duty rear axle starting in 1991, primarily in models not equipped with the optional Dana 44. Its true legendary status among off-roaders was cemented with the introduction of the 29-spline version.

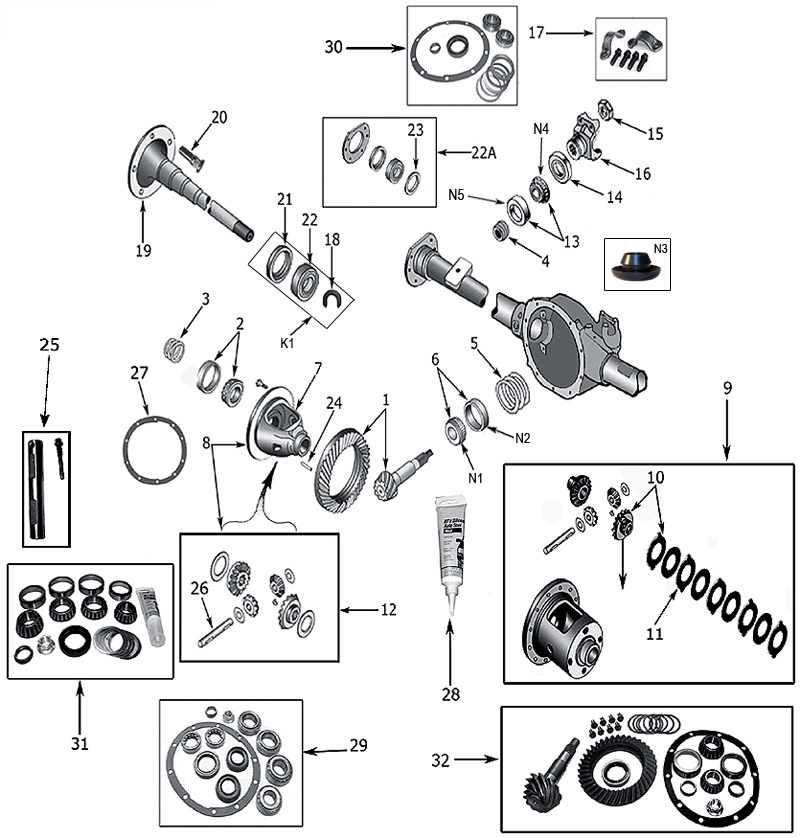

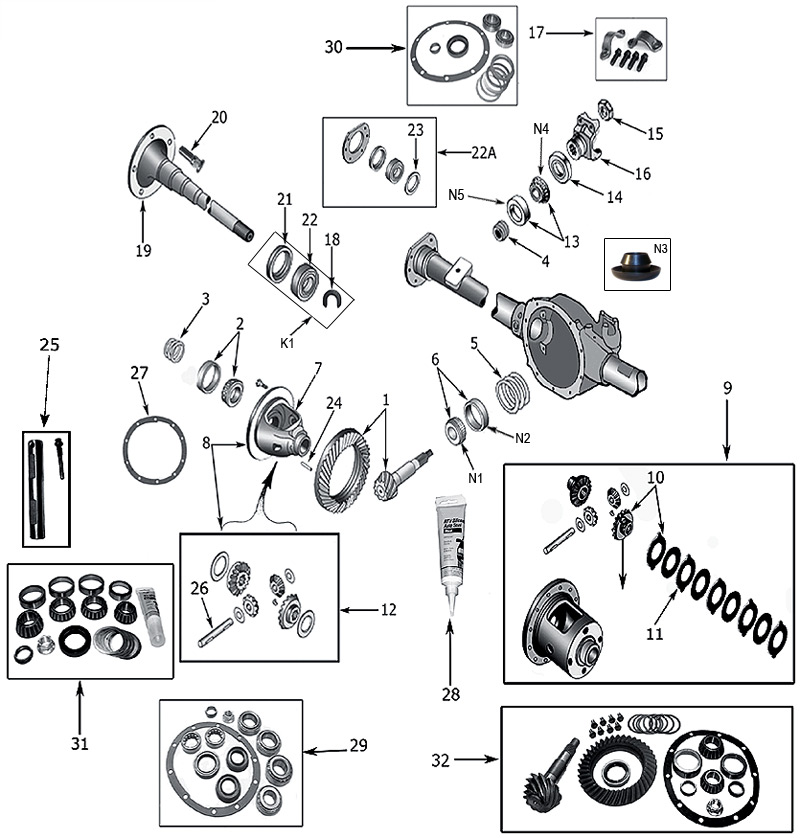

Key Features and Specifications:

- Ring Gear Diameter: 8.25 inches, providing a larger and stronger gear set compared to the Dana 35’s 7.56-inch ring gear.

- Housing Type: A robust, fabricated steel housing with a flat bottom, a distinct visual cue that differentiates it from the rounder Dana 35. It uses a C-clip design to retain the axle shafts.

- Axle Shaft Spline Count: This is the most critical distinction.

- 27-Spline (1991-1996 XJ): Stronger than the Dana 35, but still considered the weaker of the 8.25 variants. These typically came with drum brakes.

- 29-Spline (1997-2001 XJ): The highly desired version. These axle shafts are significantly thicker and stronger than the 27-spline variants, making them comparable in strength to a Dana 44 axle shaft. These typically came with drum brakes, though disc brake conversions are popular.

- Bolt Pattern: 5 on 4.5 inches, matching the XJ’s front axle.

- Overall Width: Approximately 60.5 inches (wheel mounting surface to wheel mounting surface), a direct bolt-in fit for the XJ Cherokee.

Why Choose the 8.25 for Your XJ?

The reasons for the 8.25’s popularity are clear:

- Direct Bolt-In: For 1991-2001 XJ Cherokees, the 8.25 is a direct replacement for the Dana 35, requiring no fabrication or extensive modifications to fit.

- Superior Strength: The larger ring gear and especially the thicker 29-spline axle shafts offer a substantial increase in durability, making it capable of handling larger tires (up to 35-37 inches with proper setup) and more aggressive off-road conditions than the Dana 35.

- Cost-Effective Upgrade: Compared to swapping in a Dana 44 or an aftermarket axle, acquiring and installing a used 8.25 is significantly more budget-friendly.

- Excellent Aftermarket Support: A wide array of lockers, limited-slip differentials, chromoly axle shafts, and heavy-duty differential covers are available for the 8.25.

Identifying and Locating a Chrysler 8.25 Axle For Sale

Finding the right Chrysler 8.25 axle requires a keen eye and knowledge of common donor vehicles.

Visual Cues for Identification:

- Differential Cover Shape: The 8.25 has a distinct, somewhat rectangular differential cover with a flat bottom. This is the easiest way to distinguish it from the Dana 35, which has a more oval-shaped cover with a rounded bottom. The Dana 44 typically has a more angular, hexagonal cover.

- Fill Plug Location: The fill plug on an 8.25 is usually located on the differential cover itself, whereas on a Dana 35, it’s often on the housing.

- Number of Cover Bolts: The 8.25 has 10 bolts on its differential cover.

- Axle Tube Diameter: While harder to eyeball without comparison, the 8.25 axle tubes are generally beefier than the Dana 35.

Donor Vehicles:

The primary source for a direct bolt-in Chrysler 8.25 for your XJ is another Jeep Cherokee XJ (1991-2001).

- 1991-1996 XJs: May contain the 27-spline 8.25.

- 1997-2001 XJs: Are the most desirable as they commonly contain the stronger 29-spline 8.25. Not all late-model XJs came with the 8.25; some still had the Dana 35, so always verify visually.

Where to Buy:

- Junkyards/Salvage Yards: Often the most cost-effective option. You can pull the axle yourself, which allows for thorough inspection. Be prepared with tools and a way to transport it.

- Online Marketplaces: Facebook Marketplace, Craigslist, and local classifieds are excellent sources. Search for "Jeep XJ axle," "Chrysler 8.25," or "Cherokee rear axle."

- Dedicated Jeep Forums and Classifieds: Websites like NAXJA (North American XJ Association) or Jeepforum often have "for sale" sections where members sell parts. This can be a great source for already prepped or upgraded axles.

- Specialized Jeep Parts Dealers/Wreckers: Some businesses specialize in parting out Jeeps. While potentially more expensive, they might offer cleaner axles or even ones with specific upgrades.

Important Considerations Before Purchase

Before handing over your cash, a thorough evaluation is essential to ensure you’re getting a good deal and a reliable axle.

- 27-Spline vs. 29-Spline: Reiterate: If possible, always opt for the 29-spline version (found in 1997-2001 XJs). It’s a significant strength upgrade and worth the extra effort to find. To verify spline count without pulling an axle shaft, look for a tag on the differential cover that might indicate the year or gear ratio, or visually compare the axle shaft diameter at the hub end if possible.

- Condition Assessment:

- Rust: Surface rust is common and generally fine, but deep, structural rust on the housing or control arm mounts is a red flag.

- Bends/Damage: Inspect the axle tubes for any signs of bending, especially if it came from a wrecked vehicle. Check the differential housing for cracks or impact damage.

- Leaks: Look for oil residue around the differential cover, pinion seal, and axle seals. A leaking pinion seal is common and replaceable, but multiple leaks could indicate neglect.

- Gear Ratio: Crucial for matching your front axle. Look for a metal tag on one of the differential cover bolts; it often lists the ratio (e.g., 3.55, 3.73, 4.10). If no tag, you’ll need to count teeth on the ring and pinion or rotate the wheels and driveshaft to determine the ratio. Mismatched gear ratios will damage your drivetrain.

- Axle Shafts: While you can’t easily inspect the splines without disassembly, check the wheel studs and ensure the shafts spin freely.

- Brakes: Most 8.25s come with drum brakes. Check the condition of the drums, shoes, and wheel cylinders. Consider the cost of a disc brake conversion if you desire that upgrade.

- Mileage and Donor Vehicle History: While hard to verify, knowing the general condition or mileage of the donor vehicle can offer clues about the axle’s wear.

- Inclusions: Does the sale include the complete axle assembly (housing, shafts, differential, brakes)? Are the control arm mounts and shock mounts intact?

Installation Guide (Brief Overview)

Swapping a Chrysler 8.25 into your XJ is a relatively straightforward job for a mechanically inclined individual, but it does require proper tools and safety precautions.

Tools and Supplies:

- Jack stands, floor jack

- Metric and standard sockets/wrenches

- Breaker bar, torque wrench

- Pry bar

- Cutting tools (if exhaust removal is needed)

- Brake line wrench, brake fluid

- Differential fluid (80W-90 or 75W-140, depending on use)

- RTV sealant (for diff cover)

- Optional: New U-bolts, control arm bolts, shocks, brake lines

General Steps (Highly Simplified):

- Safety First: Park on level ground, chock wheels, lift vehicle, secure with jack stands.

- Drain Fluids: Drain differential fluid.

- Remove Wheels and Brakes: Disconnect brake lines, remove drums/calipers, and rotors.

- Disconnect Components: Disconnect shock absorbers, lower control arms, upper control arms, sway bar links (if present), track bar, and driveshaft.

- Remove Old Axle: Carefully lower and remove the Dana 35.

- Install New Axle: Position the 8.25 under the vehicle. Reconnect all components in reverse order, ensuring proper torque specifications.

- Brake Reconnection: Reconnect brake lines, bleed the brake system thoroughly.

- Fill with Fluid: Add appropriate differential fluid.

- Test Drive: Perform a slow test drive to check for any issues, then re-check all fasteners after a short drive.

Professional vs. DIY: If you’re uncomfortable with suspension work, brake bleeding, or working with heavy components, it’s always best to consult a professional off-road shop.

Upgrading and Maintaining Your 8.25

The Chrysler 8.25 offers a fantastic platform for further enhancements.

Common Upgrades:

- Locker Installation: The 8.25 has excellent aftermarket support for traction devices:

- Limited-Slip Differentials (LSDs): Provide improved traction without being overly aggressive on the street.

- Automatic Lockers: Engage automatically when torque is applied (e.g., Lock-Right, Aussie Locker). Great for off-road, but can affect street manners.

- Selectable Lockers: Offer the best of both worlds, allowing you to engage/disengage traction on demand (e.g., ARB Air Locker, Eaton E-Locker).

- Chromoly Axle Shafts: For extreme off-roading or very large tires, upgrading to chromoly shafts significantly increases strength and reduces the risk of breaking axle shafts.

- Heavy-Duty Differential Covers: Protect the differential from impacts on rocks and often add structural rigidity to the housing.

- Disc Brake Conversion: Many 27-spline 8.25s came with drum brakes. Converting to rear disc brakes (often using parts from a Ford 8.8 or ZJ Grand Cherokee) provides improved stopping power and easier maintenance.

- Re-gearing: If you install significantly larger tires, re-gearing both front and rear axles to a lower ratio (e.g., 4.56, 4.88) will restore power, improve fuel economy, and reduce strain on the drivetrain.

Maintenance Tips:

- Fluid Changes: Change your differential fluid regularly, especially after water crossings or extreme off-roading. Use a quality synthetic gear oil.

- Check for Leaks: Periodically inspect the pinion seal and axle seals for any signs of leaks.

- Inspect Components: Check U-joints (if applicable), driveshaft, and mounting hardware for wear or looseness.

- Breather Hose: Ensure your axle breather hose is clear and properly routed to prevent pressure buildup and seal leaks.

Potential Challenges and Solutions

While the 8.25 is a stellar upgrade, a few considerations exist:

- Finding the Right Gearing: Locating an 8.25 with the exact gear ratio you need can be challenging. If you plan to re-gear anyway, this is less of an issue, but factor in the cost.

- C-Clip Retention: The C-clip design means the axle shafts are held in by clips inside the differential. In the rare event of an axle shaft breaking, the wheel and shaft can slide out. While this is a known characteristic, it’s not a common failure point in properly maintained axles under reasonable loads, especially with 29-spline shafts. Aftermarket C-clip eliminators exist but are often considered overkill for the 8.25.

- Worn Components: A used axle might have worn bearings, seals, or brakes. Factor in the cost of replacing these components during installation.

Chrysler 8.25 Jeep XJ Axle For Sale: Estimated Price Guide

Prices for Chrysler 8.25 axles vary significantly based on condition, spline count, included components, and geographic location. The table below provides a general range.

| Axle Type/Condition | Estimated Price Range (USD) | Key Factors Affecting Price |

|---|---|---|

| 27-Spline (1991-1996 XJ) | $150 – $350 | Basic stock axle, often with drum brakes. Condition is key. |

| 29-Spline (1997-2001 XJ) | $250 – $600 | Highly desirable, stronger axle shafts. Most sought-after. |

| Clean/Low Mileage (Any Spline) | $400 – $700+ | Excellent condition, minimal rust, good seals/bearings. |

| With Aftermarket Locker | $600 – $1200+ | Includes an LSD or locker. Type of locker significantly impacts price. |

| With Chromoly Shafts | $700 – $1500+ | Includes upgraded, stronger axle shafts. |

| Fully Built/Re-geared | $1000 – $2000+ | Re-geared to specific ratio, new bearings/seals, diff cover, etc. |

Note: These are estimated ranges. Always inspect the axle in person or request detailed photos and videos. Shipping costs can be substantial if buying from a distant seller.

Frequently Asked Questions (FAQ)

Q1: Is the Chrysler 8.25 a direct bolt-in for all Jeep XJ Cherokees?

A1: Yes, for 1991-2001 Jeep Cherokee XJs, it is a direct bolt-in replacement for the Dana 35. Earlier XJs (pre-91) with leaf springs over the axle might require minor modifications or shims.

Q2: Can I use my existing driveshaft with the 8.25 axle?

A2: In most cases, yes. The pinion yoke on the 8.25 is compatible with the stock XJ driveshaft. However, if your XJ is lifted, you may still need a slip yoke eliminator (SYE) and a new custom driveshaft to prevent driveline vibrations.

Q3: What’s the best gear ratio for the 8.25?

A3: The "best" ratio depends entirely on your tire size and intended use.

- 3.55 / 3.73: Stock-ish tires (up to 30-31 inches).

- 4.10 / 4.56: Common for 31-33 inch tires.

- 4.88 / 5.13: Ideal for 35-37 inch tires or dedicated rock crawling.

Remember, you must match the rear axle ratio to your front axle ratio.

Q4: Is the Chrysler 8.25 stronger than a Dana 44?

A4: The 29-spline Chrysler 8.25 axle shafts are often considered comparable in strength to the 30-spline Dana 44 shafts. The 8.25’s ring and pinion are also very robust. For the average XJ build running up to 35-inch tires, the 29-spline 8.25 is an excellent and often more affordable alternative to the Dana 44.

Q5: Do I need to re-gear my front axle if I install an 8.25?

A5: Yes, absolutely. Your front and rear axle gear ratios must match to prevent severe drivetrain damage, especially when operating in 4WD. If the 8.25 you acquire has a different ratio than your front axle, you will need to re-gear one or both axles to match.

Conclusion

The Chrysler 8.25 Jeep XJ axle stands as a testament to practical and effective upgrades within the off-road community. Offering a significant leap in durability and capability over the factory Dana 35, it’s a direct bolt-in solution that provides excellent strength-to-cost value. By understanding its features, knowing how to identify the desirable 29-spline version, and performing a thorough inspection before purchase, you can confidently acquire a robust foundation for your Jeep Cherokee XJ. With a relatively straightforward installation and a wealth of aftermarket support for further upgrades, the 8.25 ensures your XJ is ready to tackle tougher trails and bigger adventures, making it one of the most worthwhile modifications you can perform.