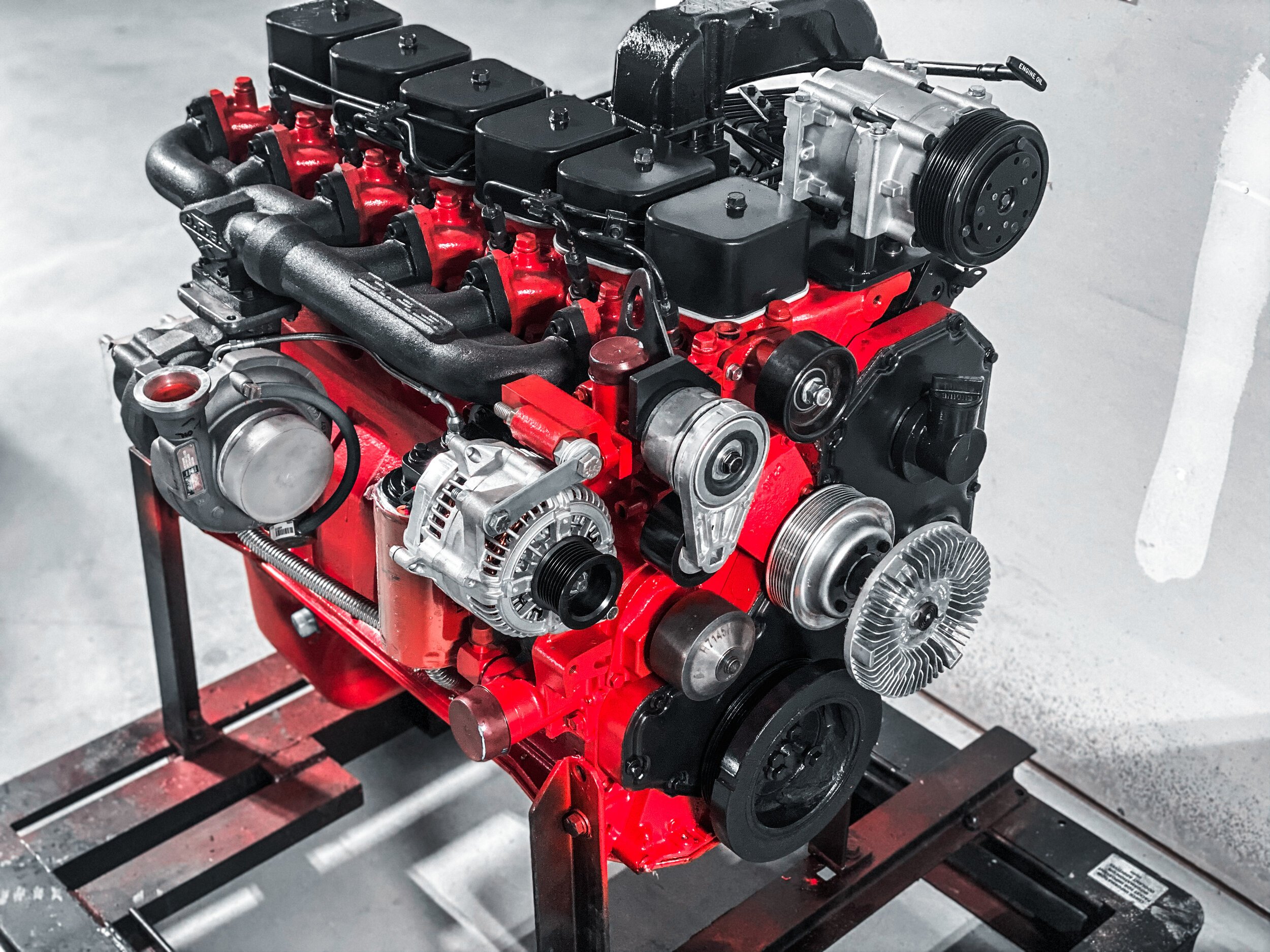

Cummins 2.8 Diesel Engine For Sale Jeep Adapter: Unleashing Torque and Efficiency in Your Off-Road Beast

Cummins 2.8 Diesel Engine For Sale Jeep Adapter: Unleashing Torque and Efficiency in Your Off-Road Beast jeeps.truckstrend.com

The allure of a diesel engine in a Jeep is undeniable. The low-end torque, impressive fuel economy, and legendary reliability of a diesel powerplant can transform an ordinary Jeep into an unstoppable off-road machine or a highly efficient daily driver. Among the various diesel swap options available, the Cummins R2.8 Turbo Diesel has emerged as a front-runner, particularly for its compact size, modern electronics, and robust performance. However, integrating this modern marvel into a classic or contemporary Jeep requires a critical component: the Jeep adapter. This comprehensive article will delve into everything you need to know about the Cummins 2.8 Diesel Engine for sale and the essential Jeep adapter that makes this popular conversion a reality.

Why Choose the Cummins R2.8 for Your Jeep?

Cummins 2.8 Diesel Engine For Sale Jeep Adapter: Unleashing Torque and Efficiency in Your Off-Road Beast

The Cummins R2.8, often referred to as the "Repower" engine, is a 2.8-liter, inline four-cylinder, common-rail turbo diesel designed specifically for the aftermarket repower market. Its popularity for Jeep swaps stems from several key advantages:

- Exceptional Torque: Diesel engines are renowned for their low-end torque, and the R2.8 delivers with 267 lb-ft at just 1,600 RPM. This is a game-changer for off-roading, crawling over obstacles, or towing, where immediate pulling power is paramount.

- Improved Fuel Economy: Compared to most gasoline Jeep engines, the R2.8 offers significantly better fuel efficiency, often delivering 25-30 MPG or more, depending on the Jeep model and driving conditions. This translates to fewer stops at the pump and longer range for overlanding adventures.

- Legendary Reliability & Longevity: Cummins has a global reputation for building durable and long-lasting diesel engines. The R2.8 is no exception, designed for years of trouble-free service.

- Compact Size: Its relatively small footprint allows it to fit into many Jeep engine bays (YJ, TJ, JK, JL, XJ, MJ) with minimal cutting or modification, making it a more accessible swap than larger diesel alternatives.

- Modern Electronics: The R2.8 comes with its own standalone ECU and wiring harness, simplifying the electrical integration into a Jeep, especially with available aftermarket CAN-bus interface modules.

- Reduced Emissions: As a modern diesel, the R2.8 meets current emissions standards, which can be crucial for legal compliance in various states.

For Jeep enthusiasts seeking a blend of power, efficiency, and reliability, the Cummins R2.8 presents a compelling upgrade over stock gasoline engines.

Understanding the Jeep Adapter Kit: The Crucial Link

The Cummins R2.8 engine is a standalone unit, but to connect it to your Jeep’s existing transmission, a specialized Jeep adapter kit is indispensable. This kit bridges the mechanical gap between the Cummins engine’s bellhousing pattern and your specific Jeep transmission’s input shaft and bolt pattern.

A typical Cummins R2.8 Jeep adapter kit usually includes:

- Bellhousing Adapter: This is the primary component, precisely machined to mate the Cummins engine block to your Jeep’s transmission bellhousing.

- Flywheel: A custom flywheel designed to bolt to the Cummins crankshaft and accommodate the Jeep’s clutch assembly (for manual transmissions) or torque converter (for automatics).

- Clutch Assembly (for Manual Transmissions): A heavy-duty pressure plate and clutch disc designed to handle the R2.8’s increased torque.

- Pilot Bearing: Ensures proper alignment and support for the transmission input shaft.

- Mounting Hardware: All necessary bolts, nuts, and washers for a secure installation.

Leading manufacturers like Advance Adapters and Quick Draw Brand are well-known for producing high-quality adapter kits for various Jeep transmissions, including:

- Manual Transmissions: AX-15, NV3550, NSG370 (from JK), and even older SM465, NV4500.

- Automatic Transmissions: 42RLE, AW4, 32RH, 46RE/RH, 545RFE.

Choosing the correct adapter kit for your specific Jeep model and transmission is paramount for a successful and trouble-free swap.

The Cummins R2.8 Jeep Swap Process: A Step-by-Step Overview

While a detailed step-by-step guide is beyond the scope of this article, understanding the general flow of a Cummins R2.8 swap can help you gauge the complexity and planning involved.

-

Planning & Preparation:

- Research: Thoroughly understand the process, gather resources, and consult online forums and experienced swappers.

- Budget: Account for the engine, adapter, and all ancillary components (fuel, cooling, exhaust, electrical, etc.), plus potential professional labor.

- Workspace & Tools: Ensure you have adequate space, a lift or engine hoist, and a full set of mechanic’s tools.

- Documentation: Photograph and label everything during disassembly.

-

Engine & Transmission Removal:

- Disconnect battery, drain fluids, remove intake, exhaust, wiring, and fuel lines.

- Unbolt the transmission from the engine and chassis.

- Carefully remove the old engine and transmission from the vehicle.

-

Chassis Preparation:

- Clean the engine bay thoroughly.

- Install new engine mounts specifically designed for the R2.8 in your Jeep chassis. These are often custom fabricated or come as part of a conversion kit.

-

Adapter & Transmission Mating:

- Install the Cummins-specific flywheel onto the R2.8 engine.

- Attach the bellhousing adapter to the Cummins engine.

- Mount the clutch assembly (if manual) or torque converter (if automatic) to the flywheel.

- Carefully mate your Jeep transmission to the adapter and secure it.

-

Engine & Transmission Installation:

- Lower the combined engine and transmission assembly into the Jeep’s engine bay, aligning with the new motor mounts.

- Secure the transmission crossmember and driveshafts.

-

Ancillary Systems Integration:

- Fuel System: Install a diesel-specific fuel pump, filter, and lines. You may need to modify your fuel tank for diesel compatibility.

- Cooling System: Install a larger, heavy-duty radiator, electric fan, and new hoses suitable for diesel cooling requirements.

- Exhaust System: Fabricate or install a custom exhaust downpipe and system to accommodate the turbocharger and routing.

- Electrical System: This is often the most challenging part. Integrate the Cummins ECU and wiring harness with your Jeep’s electrical system (gauges, lights, ignition, etc.). Aftermarket modules like "Canzilla" can greatly simplify this.

- Air Intake: Design and install an air intake system, ensuring proper filtration for the diesel engine.

-

Fluid Filling & Initial Startup:

- Fill all fluids (engine oil, coolant, transmission fluid).

- Perform a thorough inspection for leaks or loose connections.

- Bleed the fuel system.

- Attempt initial startup, checking for proper operation and addressing any diagnostic codes.

-

Testing & Tuning:

- Gradually test the vehicle under various conditions.

- Monitor temperatures, pressures, and performance.

- Address any vibrations, noises, or drivability issues.

Essential Considerations Before Your Swap

Before committing to a Cummins R2.8 swap, carefully consider these critical factors:

- Legal & Emissions Compliance: This is paramount. Research your local and state laws regarding engine swaps and diesel emissions. Some states (like California) have strict regulations. The Cummins R2.8 is EPA compliant, which helps, but individual state rules vary.

- Budget Beyond the Engine & Adapter: The engine and adapter are just the beginning. Factor in costs for motor mounts, radiator, intercooler (if desired), fuel lines, wiring harness, exhaust, potential transmission upgrades, axle upgrades, and countless small parts.

- Transmission Compatibility & Strength: While adapters exist for many Jeep transmissions, ensure your chosen transmission can handle the R2.8’s torque, especially if you plan on heavy off-roading or towing. You might need to upgrade to a stronger unit like an NV4500 or a beefed-up automatic.

- Axles & Driveline: The increased torque will put more strain on your axles, driveshafts, and differentials. Consider upgrading these components to prevent failures, especially if you have weaker stock axles.

- Suspension: The R2.8 is heavier than most gasoline Jeep engines, which might require stiffer front springs or a dedicated lift kit to maintain proper ride height and handling.

- Electrical System Integration: While the R2.8’s standalone ECU simplifies things, integrating it with your Jeep’s gauges, cruise control, and other accessories requires careful wiring. This is often where many DIY swappers seek professional help.

- Cooling System Capacity: Diesel engines run hotter than gasoline engines. An upgraded, larger radiator and efficient fan setup are non-negotiable to prevent overheating.

- Skill Level & Resources: This is not a beginner’s project. It requires mechanical aptitude, electrical knowledge, and problem-solving skills. If you’re not comfortable with extensive fabrication, wiring, and troubleshooting, factor in professional installation costs.

Tips for a Successful R2.8 Conversion

- Research Extensively: Join online forums (e.g., Pirate4x4, Jeep forums, Cummins Repower groups), watch YouTube videos, and read build threads. Learn from others’ experiences.

- Source Quality Parts: Don’t cut corners on the engine, adapter kit, or critical ancillary components. Cheap parts can lead to costly failures down the road.

- Plan Meticulously: Create a detailed parts list, a step-by-step plan, and a realistic budget. Anticipate potential challenges.

- Don’t Rush: Take your time. A rushed swap often leads to mistakes, frustration, and rework.

- Test Thoroughly: After the swap, thoroughly test all systems before putting the Jeep into demanding service.

Addressing Potential Challenges

- Space Constraints: While compact, the R2.8 can still be a tight fit in some older Jeep models, requiring minor firewall notching or fan shroud modifications.

- Wiring Complexities: Even with modern standalone ECUs, integrating the Cummins engine’s signals with the Jeep’s gauges and electronics can be daunting. Aftermarket solutions exist to simplify this.

- NVH (Noise, Vibration, Harshness): Diesel engines inherently produce more noise and vibration than gasoline engines. Proper motor mounts, exhaust routing, and sound deadening can mitigate this.

- Parts Availability & Lead Times: Some specialized swap components might have lead times, so order well in advance.

- Emissions & Inspection: Navigating state-specific emissions testing and vehicle inspection post-swap can be challenging. Ensure you have all necessary documentation.

Price Table: Cummins R2.8 Diesel Engine & Jeep Adapter Components

The total cost of a Cummins R2.8 Jeep swap can vary widely depending on whether you DIY, the condition of the engine (new vs. used), and the specific components chosen. Below are estimated price ranges for core components:

| Component | Description | Estimated Price Range (USD) | Notes |

|---|---|---|---|

| Cummins R2.8 Crate Engine | Brand new, complete engine package from Cummins Repower. | $9,000 – $11,000 | Includes engine, ECU, wiring harness, accelerator pedal, air filter. Most common and recommended option for reliability. |

| Used Cummins R2.8 Engine | Pulled from a vehicle, often with unknown mileage/condition. | $4,000 – $7,000 | Less common for swaps due to warranty and reliability concerns; often requires rebuild or extensive checks. |

| Jeep Transmission Adapter Kit | Bellhousing adapter, flywheel, clutch (if manual), pilot bearing, hardware. Specific to your Jeep transmission. | $1,500 – $2,500 | Key brands include Advance Adapters, Quick Draw Brand. Price varies by transmission and included components. |

| Engine Mounts (Conversion Specific) | Custom mounts to fit the R2.8 into your Jeep chassis. | $300 – $600 | Essential for proper engine placement and vibration dampening. |

| Fuel System Components | Diesel fuel pump, filter, lines, potential tank modifications. | $200 – $500 | Ensures proper fuel delivery and filtration for diesel. |

| Cooling System Upgrade | Larger radiator, electric fan, hoses, overflow tank. | $500 – $1,000 | Critical for maintaining optimal engine temperature. |

| Exhaust System Components | Custom downpipe, piping, muffler for turbo diesel. | $300 – $800 | Must be routed to clear chassis and driveline. |

| Wiring Harness & Integration Module | Adapting Cummins ECU to Jeep gauges, lights, and other systems (e.g., Canzilla, custom harnesses). | $500 – $1,500 | Simplifies electrical communication between engine and vehicle. |

| Miscellaneous Parts | Hoses, clamps, fluids, sensors, small brackets, hardware, wiring accessories, etc. | $500 – $1,500 | These often overlooked "small" costs can add up quickly. |

| Professional Installation Labor | If you opt for a shop to perform the swap. | $4,000 – $10,000+ | Highly variable based on shop rates, complexity, and unforeseen issues. This can significantly increase the total cost. |

| Total Estimated DIY Cost (Core Swap) | Engine + Adapter + Essential Ancillaries (Excludes Labor, Major Driveline Upgrades) | $12,300 – $17,000 | This is a realistic range for major components and essential supporting parts if you do the work yourself. |

| Total Estimated Professional Swap Cost | Engine + Adapter + All Ancillaries + Labor | $16,300 – $27,000+ | This broad range reflects variability in labor rates, specific part choices, and the extent of additional upgrades. Can exceed this range for high-end builds. |

Note: These prices are estimates and can fluctuate based on market demand, supplier, and specific component choices. Always obtain current quotes for accurate budgeting.

Frequently Asked Questions (FAQ)

Q1: Is the Cummins R2.8 swap street legal?

A1: The R2.8 is EPA compliant, which is a good start. However, street legality depends heavily on your specific state and local emissions laws. Some states (like California) have very strict rules for engine swaps. Always research your local Department of Motor Vehicles (DMV) or equivalent agency’s regulations before starting.

Q2: How much does a typical Cummins R2.8 Jeep swap cost?

A2: As detailed in the price table, a DIY swap (engine, adapter, and essential parts) can range from $12,000 to $17,000. If you hire a professional shop, the total cost can easily climb to $16,000 to $27,000 or more, including labor.

Q3: What Jeep models are best suited for the R2.8 swap?

A3: The R2.8 is compact enough to fit into a wide range of Jeeps, including YJ, TJ, LJ, JK, JL, XJ (Cherokee), and MJ (Comanche). The JK/JL models often have more modern electronics to contend with, but adapter kits and wiring solutions exist.

Q4: How difficult is the R2.8 swap for a DIYer?

A4: It’s a challenging but achievable project for an experienced home mechanic with good fabrication, electrical, and mechanical skills. It’s not recommended for a first-time engine swap. Patience, thorough research, and a willingness to troubleshoot are essential.

Q5: What kind of fuel economy can I expect after the swap?

A5: Many R2.8 swappers report fuel economy in the range of 25-30 MPG, significantly better than most gasoline Jeep engines. Actual mileage will vary based on Jeep model, gearing, tire size, driving habits, and terrain.

Q6: Do I need to upgrade my Jeep’s transmission or axles?

A6: While adapter kits exist for many stock Jeep transmissions, the R2.8’s significantly higher torque can overwhelm weaker units (e.g., AX-5, some automatic transmissions). Upgrading to a stronger transmission (like an NV4500) and/or heavier-duty axles may be necessary, especially if you plan on aggressive off-roading or towing.

Q7: What kind of maintenance does the R2.8 require?

A7: Standard diesel maintenance includes regular oil and filter changes, fuel filter replacement, air filter checks, and monitoring coolant levels. Diesel engines generally have longer service intervals for major components than gasoline engines but require specific diesel-rated fluids.

Conclusion

The Cummins R2.8 Diesel Engine, combined with the right Jeep adapter, offers an enticing path to transforming your Jeep into a more capable, efficient, and reliable vehicle. The allure of robust low-end torque, impressive fuel economy, and Cummins’ legendary durability makes this swap highly desirable for off-road enthusiasts and daily drivers alike. While it’s a significant undertaking requiring careful planning, a substantial budget, and considerable mechanical skill, the rewards of a diesel-powered Jeep that can conquer any terrain with ease are well worth the effort. Do your homework, budget wisely, and prepare for a rewarding journey that will unleash the full potential of your Jeep.