Fiberglass Jeep Bodies For Sale: Revitalizing Your Off-Road Legend

Fiberglass Jeep Bodies For Sale: Revitalizing Your Off-Road Legend jeeps.truckstrend.com

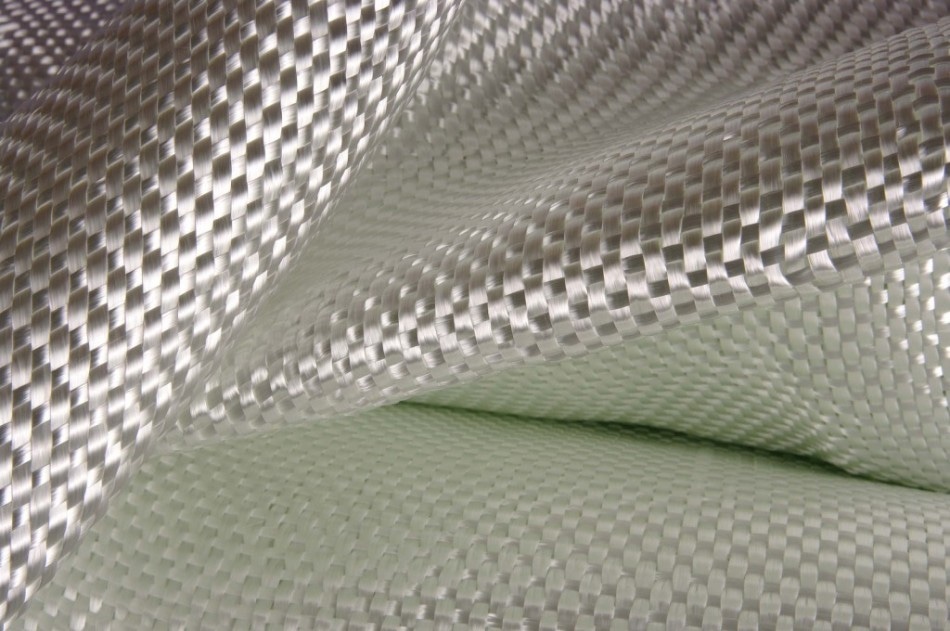

The iconic Jeep, with its rugged charm and unparalleled off-road capability, has captured the hearts of enthusiasts for generations. However, time and the elements are often unkind to their original steel bodies, leading to the dreaded "Jeep rust." For many, this marks the end of the road, but for a growing number of savvy owners, it’s an opportunity to breathe new life into their beloved rigs. Enter fiberglass Jeep bodies for sale – a revolutionary solution that offers a durable, lightweight, and rust-proof alternative to traditional steel, allowing classic Jeeps to conquer trails and turn heads for decades to come.

This comprehensive guide will delve into everything you need to know about fiberglass Jeep bodies, from their inherent advantages and available types to critical considerations, installation insights, and maintenance tips. Whether you’re planning a full restoration, a custom build, or simply looking to replace a rusted-out tub, understanding the world of fiberglass will equip you to make an informed decision and embark on your next Jeep adventure with confidence.

Fiberglass Jeep Bodies For Sale: Revitalizing Your Off-Road Legend

Why Choose Fiberglass? Unpacking the Benefits

The decision to opt for a fiberglass Jeep body over repairing or replacing a steel one often comes down to a compelling list of advantages that address the common pain points of vintage vehicle ownership.

- Corrosion Resistance: This is, without a doubt, the number one reason enthusiasts turn to fiberglass. Unlike steel, fiberglass does not rust, corrode, or rot. This means no more patching holes, no more endless sanding, and no more structural compromise due to oxidation. For Jeeps that live in harsh climates or are frequently exposed to moisture and salt, fiberglass offers unparalleled longevity.

- Lightweight Construction: Fiberglass is significantly lighter than steel. A fiberglass tub can shave hundreds of pounds off the vehicle’s total weight. This weight reduction translates directly into improved fuel economy, better acceleration, and enhanced suspension performance, especially beneficial for off-road articulation and handling.

- Durability and Strength: Modern fiberglass composites are incredibly strong and resilient. While often perceived as brittle, high-quality fiberglass bodies are designed to withstand the rigors of off-roading, impacts, and daily driving. They flex rather than dent or crease like steel, and minor damage is often easier to repair than equivalent damage to steel.

- Ease of Repair: Should a fiberglass body sustain damage, repairs are typically straightforward using readily available fiberglass repair kits. Unlike steel, which often requires welding and specialized bodywork, fiberglass can be patched, sanded, and painted with relative ease, making DIY repairs more accessible.

- Customization Potential: Fiberglass is a versatile material that lends itself well to modification. For those looking to create a truly unique Jeep, fiberglass allows for easier cutting, shaping, and bonding of custom features, flares, or panel extensions without the need for extensive metal fabrication skills.

- Cost-Effectiveness: While the initial outlay for a fiberglass body might seem significant, it often becomes more cost-effective in the long run compared to extensive steel body repair, which can involve countless hours of labor, specialty tools, and expensive patch panels. For a truly rust-free foundation, fiberglass often presents a more economical and durable solution.

.jpg)

Types of Fiberglass Jeep Bodies Available

The market for fiberglass Jeep bodies is diverse, catering to various models and project needs. Understanding the different types can help narrow down your search.

- Full Tubs (Complete Body Replacements): These are the most popular offering, providing a complete, one-piece body that replaces the original steel tub. They typically include the floor, inner and outer fenders, firewall, and rear panel. Full tubs are available for a wide range of classic Jeep models, predominantly:

- Willys MB/Ford GPW (WWII Era): Perfect for historical restorations without the rust headache.

- CJ Series (CJ-2A, CJ-3A, CJ-5, CJ-7, CJ-8 Scrambler): These are by far the most common applications for fiberglass, as many original CJ bodies have succumbed to rust. You can find exact replicas or slightly modified versions.

- YJ Wrangler (1987-1995): While less prevalent than CJ tubs, YJ fiberglass tubs are available for those seeking to revitalize the square-headlight era Wrangler.

- TJ Wrangler (1997-2006): Less common, as TJ bodies are generally more rust-resistant than older models, but still an option for severe cases.

- Individual Panels: For those whose bodies are only partially rusted or who want to upgrade specific components, individual fiberglass panels are available. These include:

- Fenders (front and rear)

- Hoods

- Grille assemblies

- Tailgates

- Dashboards

- Windshield frames

- Replica vs. Custom/Modified: Most fiberglass bodies are designed as direct replacements, replicating the original dimensions and mounting points. However, some manufacturers offer slightly modified designs, such as wider fender flares integrated into the body, or designs optimized for specific aftermarket components.

Key Considerations Before You Buy

Purchasing a fiberglass Jeep body is a significant investment and a foundational decision for your project. Careful consideration before buying is paramount to ensure satisfaction and avoid costly mistakes.

- Quality and Manufacturer Reputation: Not all fiberglass is created equal. Research manufacturers thoroughly. Look for companies with a long-standing reputation for quality, consistent product, and good customer service. Read reviews, check forums, and ask for references. High-quality bodies use multiple layers of fiberglass mat and resin, often with reinforcing materials in high-stress areas.

- Fitment and Compatibility: Ensure the fiberglass body is specifically designed for your Jeep’s frame and year. While most are direct bolt-on replacements, minor adjustments may be necessary. Inquire about the accuracy of the mounting holes and body lines.

- Material Thickness and Layup: Ask the manufacturer about the thickness of the fiberglass and the number of layers (layup) used. Thicker, multi-layered construction generally indicates a stronger, more durable product.

- Finish Quality: Inspect photos (or the body in person, if possible) for a smooth, consistent gel coat finish. Look for signs of ripples, unevenness, excessive pinholes, or stress cracks. A good gel coat provides a solid foundation for paint and indicates careful manufacturing.

- Included Components: Clarify exactly what comes with the body. Does it include inner fenders, dash mounts, seat belt mounting points, or mounts for the windshield frame? Sometimes these are separate pieces or require fabrication.

- Shipping and Handling: Fiberglass bodies are large and can be fragile during transport. Discuss shipping methods, crating, and insurance with the seller. Upon delivery, thoroughly inspect the body before signing off on the shipment. Document any damage with photos immediately.

- Legalities and Registration: While generally not an issue for body swaps, it’s wise to check your local vehicle registration laws, especially if you’re importing a body or making significant structural modifications.

The Installation Process: A DIYer’s Guide (and When to Call a Pro)

Installing a fiberglass Jeep body is a rewarding project for the moderately skilled DIY enthusiast, but it requires patience, attention to detail, and a good set of tools.

- Preparation: The first step involves completely stripping your old Jeep body from the frame. This includes removing all interior components, wiring, fuel lines, brake lines, steering column, and anything else attached to the tub. This is an excellent opportunity to inspect, clean, and possibly repair or paint your chassis.

- Test Fit: Before doing any drilling or permanent mounting, carefully test-fit the new fiberglass tub onto the frame. This allows you to identify any alignment issues, confirm mounting points, and plan for component transfer.

- Mounting: Fiberglass bodies typically bolt directly to the factory frame mounts using existing hardware or new bolts. Ensure all mounting points are secure and properly torqued. Some builders add body mounts or shims for optimal alignment and vibration dampening.

- Component Transfer: This is often the most time-consuming part. You’ll need to transfer all your interior components – dashboard, steering column, pedals, seats, roll bar, wiring harness, fuel tank, and brake lines – from your old body to the new fiberglass one. This may involve drilling new holes (carefully!) or adapting existing mounts.

- Finishing and Paint: Once the body is mounted and all components are transferred, the fiberglass will need to be prepped for paint. This involves cleaning, light sanding, and applying an appropriate primer designed for fiberglass. Professional paint application will yield the best and most durable results.

- Tools Required: Basic hand tools, a good set of wrenches and sockets, drills, a grinder, measuring tape, and possibly a floor jack or engine hoist (for safely lifting the body).

- Difficulty Level: While many DIYers successfully tackle this project, it’s not a beginner-level task. Knowledge of automotive systems (electrical, fuel, brakes) and general mechanical aptitude are highly recommended. If you’re uncomfortable with any aspect, consider hiring a professional shop specializing in restorations or custom builds.

Maintaining Your Fiberglass Jeep Body

One of the great advantages of fiberglass is its low maintenance, but a few simple practices will ensure its longevity and appearance.

- Regular Cleaning: Treat your fiberglass body like any other vehicle. Wash it regularly with automotive soap and water to remove dirt, mud, and grime.

- Protecting the Finish: If your body has a gel coat, or once it’s painted, apply a good quality automotive wax or sealant regularly. This protects the finish from UV rays, which can cause fading and chalking over time, and helps maintain its shine.

- Repairing Minor Damage: Small scratches or chips in the gel coat can often be repaired with a fiberglass gel coat repair kit. Larger cracks or punctures can be fixed with fiberglass repair kits, involving resin and fiberglass mat. Always follow the product instructions carefully.

- Inspecting Mounts: Periodically check all body mounting bolts and hardware for tightness, especially after off-roading or rough use.

Challenges and Solutions

While fiberglass offers numerous advantages, it’s important to be aware of potential challenges.

- Flex vs. Rigidity: Fiberglass bodies can exhibit more flex than steel. While this can be beneficial in absorbing impacts, excessive flex might lead to stress cracks in the paint or body if not properly reinforced or mounted.

- Solution: Ensure proper frame preparation, use all factory mounting points, and consider adding additional cross-bracing or body mounts if the manufacturer recommends it or if you plan extreme off-roading.

- Paint Adhesion: Fiberglass requires specific preparation for paint to adhere properly and last. Improper prep can lead to peeling or bubbling.

- Solution: Use a primer specifically designed for fiberglass or composite materials. Ensure the surface is thoroughly cleaned, scuffed, and free of oils or contaminants before priming and painting. Professional painting is often recommended for best results.

- Cost of Ancillary Parts: Remember that the fiberglass body is just the shell. You’ll still need to factor in the cost of all the small parts, hardware, wiring, and potentially new interior components or a paint job.

- Solution: Create a detailed budget that includes all potential costs beyond just the body itself.

- Shipping Damage: As mentioned, fiberglass bodies are large and can be damaged during shipping.

- Solution: Always inspect the package thoroughly upon arrival and document any damage before accepting delivery. File a claim with the shipping company immediately if damage is found.

Price Table: Estimated Costs for Fiberglass Jeep Bodies

The cost of a fiberglass Jeep body varies significantly based on the Jeep model, the manufacturer, the completeness of the body (full tub vs. individual panels), and the quality of construction. The prices below are estimated ranges in USD and are subject to change. They do not include shipping, paint, or installation labor.

| Jeep Model (Year Range) | Body Type | Estimated Price Range (USD) | Key Features/Notes |

|---|---|---|---|

| Willys MB / Ford GPW | Full Tub | $3,500 – $6,000 | Authentic replica; often requires extensive component transfer. |

| CJ-2A / CJ-3A | Full Tub | $3,000 – $5,500 | Early flatfender models; simple, rugged design. |

| CJ-5 | Full Tub | $3,200 – $5,800 | Short wheelbase; popular for classic off-road builds. |

| CJ-7 | Full Tub | $3,500 – $6,500 | Longest wheelbase CJ; most popular for fiberglass due to rust issues. |

| CJ-8 Scrambler | Full Tub | $4,500 – $8,000 | Rare and highly sought after; extended wheelbase pick-up style. |

| YJ Wrangler (87-95) | Full Tub | $4,000 – $7,000 | Square headlight model; less common but available. |

| TJ Wrangler (97-06) | Full Tub | $4,500 – $7,500 | Less common for fiberglass; typically for severe rust or custom builds. |

| All CJ/YJ Models | Front Fenders (pr) | $300 – $600 | Individual replacement panels. |

| All CJ/YJ Models | Hood | $300 – $550 | Individual replacement panels. |

| All CJ/YJ Models | Grille | $200 – $400 | Individual replacement panels. |

| All CJ/YJ Models | Tailgate | $150 – $300 | Individual replacement panels. |

Disclaimer: Prices are estimates and highly variable based on manufacturer, material quality, and current market conditions. Always request a detailed quote.

Frequently Asked Questions (FAQ)

Q: Is fiberglass as strong as steel?

A: High-quality fiberglass, when properly constructed with multiple layers and reinforcements, can be incredibly strong and durable, often outperforming steel in impact resistance (flexes instead of dents) and certainly in corrosion resistance. However, it behaves differently under stress.

Q: Can I paint fiberglass myself?

A: Yes, you can. However, proper preparation (cleaning, sanding, and using an appropriate primer for composites) is crucial for good adhesion and a lasting finish. For the best results and a professional look, a professional automotive painter is recommended.

Q: Do fiberglass bodies rust?

A: No, fiberglass itself is a composite material that does not rust, corrode, or rot, making it an excellent long-term solution for areas prone to rust.

Q: How much lighter is fiberglass than steel?

A: A fiberglass Jeep tub can be anywhere from 100 to 300 pounds lighter than its steel counterpart, depending on the model and specific construction. This weight savings improves performance and fuel efficiency.

Q: Is it difficult to install a fiberglass body?

A: It’s a moderate to advanced DIY project. While fiberglass bodies are designed to bolt directly to the frame, transferring all the internal components (wiring, fuel lines, dash, etc.) requires patience, mechanical aptitude, and attention to detail.

Q: Where can I buy a good quality fiberglass body?

A: Reputable manufacturers specialize in fiberglass Jeep bodies. Search online forums, Jeep enthusiast groups, and well-known aftermarket parts suppliers. Brands with a long history and positive reviews are a good starting point.

Q: Do I need a special frame for a fiberglass body?

A: No, fiberglass Jeep bodies are designed to bolt directly to the original factory frame for the specific model year they are replacing. No special frame modifications are typically needed.

Q: Will my original doors/hood/windshield fit?

A: Most fiberglass full tubs are designed to accept original steel doors, hoods, and windshield frames as direct bolt-on components. However, always confirm compatibility with the manufacturer before purchasing, as minor adjustments may sometimes be necessary.

Conclusion: Revitalizing Your Ride with Fiberglass

Fiberglass Jeep bodies represent a compelling and increasingly popular solution for breathing new life into classic Jeeps. They offer a definitive answer to the perennial problem of rust, providing a lightweight, durable, and easily repairable foundation for your restoration or custom build. The benefits extend beyond mere rust prevention, enhancing performance, simplifying maintenance, and opening up new avenues for customization.

While the initial investment and the installation process require careful consideration, the long-term value, reduced maintenance, and the sheer joy of driving a rust-free, revitalized legend make fiberglass an incredibly worthwhile choice. By understanding the options, asking the right questions, and approaching the project with informed enthusiasm, you can transform your old, tired Jeep into a head-turning, trail-conquering machine that will continue its legacy for generations to come.