Fiberglass Jeep Bodies For Sale: Your Ultimate Guide to Rust-Free Restoration and Customization

Fiberglass Jeep Bodies For Sale: Your Ultimate Guide to Rust-Free Restoration and Customization jeeps.truckstrend.com

For generations, the Jeep has stood as an icon of adventure, utility, and freedom. From the battlefields of WWII to the most challenging off-road trails, its rugged spirit has captivated enthusiasts worldwide. However, the very metal that forms the classic Jeep body is susceptible to an insidious enemy: rust. Decades of exposure to elements, road salt, and harsh conditions often leave these beloved vehicles with crumbling floors, corroded fenders, and disintegrated body mounts. This is where the solution of Fiberglass Jeep Bodies For Sale emerges as a game-changer, offering a durable, rust-proof, and lightweight alternative that breathes new life into vintage Jeeps and empowers custom builders.

Fiberglass Jeep bodies are precisely molded replicas of original steel bodies or individual panels, meticulously crafted from layers of resin-impregnated glass fibers. They represent a significant shift in how Jeep owners approach restoration, customization, and even performance enhancement. More than just a replacement part, a fiberglass body is an investment in longevity, offering a host of advantages that traditional steel simply cannot match, ensuring your classic Jeep endures for generations to come, free from the endless battle against corrosion.

Fiberglass Jeep Bodies For Sale: Your Ultimate Guide to Rust-Free Restoration and Customization

Why Choose a Fiberglass Jeep Body? The Undeniable Advantages

Opting for a fiberglass Jeep body isn’t just about avoiding rust; it’s about embracing a superior material that offers a multitude of benefits for restoration projects, off-road enthusiasts, and customizers alike.

1. Unrivaled Corrosion Resistance: The End of Rust

This is, without a doubt, the primary motivator for most buyers. Fiberglass is inherently impervious to rust and corrosion. Unlike steel, which begins to degrade the moment its protective paint or coating is compromised, fiberglass remains structurally sound regardless of moisture, salt, or chemical exposure. For Jeeps that will see trail duty, be stored outdoors, or live in rust-prone climates, a fiberglass body eliminates the single biggest headache of classic vehicle ownership: the never-ending fight against rust. This translates into significantly reduced maintenance costs and a consistently pristine appearance over the vehicle’s lifetime.

2. Significant Weight Reduction: Performance & Efficiency Gains

Fiberglass bodies are considerably lighter than their steel counterparts. While the exact weight savings vary by model and manufacturer, a full fiberglass tub can shave hundreds of pounds off the vehicle’s total weight. This reduction translates directly into:

- Improved Fuel Economy: Less weight means the engine works less to move the vehicle.

- Enhanced Performance: Quicker acceleration and better power-to-weight ratio.

- Reduced Wear and Tear: Lighter weight puts less stress on suspension components, brakes, tires, and the drivetrain, potentially extending their lifespan.

- Better Off-Road Agility: A lighter vehicle can navigate obstacles with greater ease and put less strain on recovery equipment.

3. Exceptional Durability and Impact Resistance

Despite common misconceptions, modern fiberglass composites are incredibly strong and resilient. They possess a degree of flex that steel often lacks, allowing them to absorb impacts without deforming or creasing permanently. In the event of an off-road scrape or minor collision, fiberglass can often "bounce back" or sustain less severe damage than steel. Furthermore, repairs to fiberglass are often simpler and more straightforward than complex metalwork, welding, and panel beating required for steel. Small cracks or holes can be patched with fiberglass repair kits, restoring the body’s integrity relatively easily.

4. Simplified Restoration and Customization

Working with fiberglass is generally easier than working with steel. It can be cut, drilled, sanded, and bonded with relative ease using common tools. This makes it a favored material for customizers looking to stretch a tub, add custom storage compartments, or integrate unique features. For restorers, the absence of rust means no cutting out rusted sections, no welding new patches, and no extensive body filler work. The body arrives ready for final prep and paint, significantly shortening the restoration timeline and reducing labor costs.

5. Long-Term Cost-Effectiveness

While the initial purchase price of a fiberglass body might seem higher than finding a rusty used steel body, the long-term cost savings are substantial. You eliminate the need for costly rust repair, panel replacement, and extensive bodywork. The reduced weight can save on fuel and component wear. Ultimately, a fiberglass body ensures your investment lasts longer and maintains its value, free from the silent, destructive march of rust.

Types of Fiberglass Jeep Bodies Available

The market for Fiberglass Jeep Bodies For Sale is diverse, catering to various Jeep models and restoration needs. Understanding the available options is crucial for making the right choice.

1. Full Tubs (Complete Body Replacements)

These are the most comprehensive option, providing an entirely new body shell that mounts directly onto your existing Jeep frame. Full tubs are popular for:

- Vintage CJ Series: Especially CJ-2A, CJ-3A, CJ-3B, CJ-5, CJ-7, and CJ-8 Scrambler. These models have separate body-on-frame designs that are ideal for body swaps.

- WWII Replicas: High-quality fiberglass replicas of Willys MB and Ford GPW bodies are widely available for authentic restorations or new builds.

- YJ Wrangler: While less common than for CJs, full fiberglass tubs are available for the YJ, offering a rust-free solution for this popular square-headlight model.

- Modern Wranglers (TJ/JK/JL): Full fiberglass tubs are rare for these models due to their more integrated unibody/frame designs and complex electronics, though individual panels may be available.

Full tubs typically include the main floor, side panels, firewall, and often the dash and tailgate opening. They usually require the transfer of all original components like the windshield frame, doors, seats, wiring, and drivetrain.

2. Individual Replacement Panels

For those who don’t need an entire body but have specific rusted-out sections, individual fiberglass panels are an excellent solution. Common options include:

- Fenders: Front and rear fenders are prone to rust and damage.

- Hoods: Lightweight and rust-free alternatives.

- Grilles: Often found on vintage Jeeps like the CJ-2A/3A or WWII models.

- Tailgates: Rust-prone and easily damaged.

- Dashboards: For those looking for a clean, crack-free dash.

- Floor Pans: Ideal for patching localized rust spots.

These panels are designed to bolt or bond directly in place of the original steel components, making localized repairs much simpler and more durable.

3. Specialty and Custom Bodies

Beyond standard replicas, some manufacturers offer specialty fiberglass bodies:

- Stretched Tubs: Longer than original, often for custom builds requiring more passenger or cargo space.

- Race/Lightweight Bodies: Designed for extreme off-road racing, prioritizing minimal weight and maximum durability.

- Unique Designs: Some companies produce highly modified or original designs based on Jeep platforms.

When considering any of these types, always verify compatibility with your specific Jeep model and year.

What to Look For When Buying a Fiberglass Jeep Body

Purchasing a fiberglass Jeep body is a significant investment. Careful consideration of these factors will ensure you get a high-quality product that meets your needs.

1. Manufacturer Reputation and Quality

Not all fiberglass is created equal. Research manufacturers thoroughly. Look for companies with a long history, positive customer reviews, and a reputation for quality control.

- Construction Method: Ask if the body is hand-laid (stronger, more consistent) or chop-gun molded (faster, but potentially less uniform).

- Thickness: Ensure adequate material thickness for strength and durability. Thicker is generally better.

- Gel Coat Quality: A good quality, smooth gel coat indicates a well-finished mold and provides a better surface for painting. Avoid bodies with excessive pinholes, waves, or inconsistencies.

2. Fit and Finish Accuracy

The most critical aspect after material quality is how well the body fits.

- Dimensional Accuracy: Does it match original dimensions precisely? This affects how well your existing doors, windshield, and other components will fit.

- Symmetry: Check for symmetry across the body.

- Pre-Drilled Holes: Are mounting holes, hinge holes, and accessory holes accurately placed and properly sized? Incorrectly drilled holes can lead to significant headaches during assembly.

- Warping/Distortion: Fiberglass can warp if not properly cured or stored. Inspect for any signs of distortion.

3. Included Components

Understand what comes with the body. Some full tubs are truly "bare," while others might include integrated dash panels, inner fender wells, or a tailgate opening. Clarify what is included and what you’ll need to source separately.

4. Mounting Points and Frame Compatibility

Ensure the fiberglass body is designed to bolt directly to your specific Jeep frame (e.g., CJ-7 frame). Verify the number and location of body mounts. Some manufacturers offer different mounting options or require specific frame modifications.

5. Shipping Considerations

Fiberglass bodies are large and require specialized shipping.

- Packaging: How will it be crated or packaged to prevent damage during transit?

- Shipping Cost: Obtain an accurate shipping quote, as this can be a significant expense.

- Inspection upon Delivery: Thoroughly inspect the body for any shipping damage before signing off on delivery.

6. Legal Considerations (VIN Plate)

For a full body replacement, you will need to transfer your original VIN plate to the new fiberglass body. Understand the legal requirements in your state regarding VIN transfer and title implications. Some states require inspection or specific procedures for vehicles with replacement bodies.

The Installation Process: What to Expect

Installing a fiberglass Jeep body is a significant project, but entirely achievable for a mechanically inclined individual. Here’s a general overview of the steps involved:

1. Preparation of the Frame

- Removal of Old Body: Carefully unbolt and lift off the old steel body. This is often the most challenging part due to rusted bolts.

- Frame Inspection and Repair: Thoroughly inspect your frame for rust, cracks, or damage. Address any issues with welding or reinforcement.

- Cleaning and Painting: Clean the frame thoroughly and apply a protective coating (e.g., POR-15, chassis paint) to prevent future rust.

2. Test Fitting the Fiberglass Body

This is a critical, often repeated step.

- Initial Placement: Carefully lower the fiberglass body onto the frame.

- Alignment: Check alignment with the frame, ensuring it sits level and square.

- Component Fitment: Test fit major components like the windshield frame, doors, and steering column to identify any potential fitment issues early. Shims may be required at body mounts to achieve proper alignment.

3. Mounting the Body

- Body Mounts: Secure the fiberglass body to the frame using new body mount hardware and bushings. Do not overtighten, as fiberglass can crack under excessive pressure.

- Bracing (if applicable): Some bodies may require additional internal bracing for rigidity or for mounting specific components.

4. Transferring Components

This is where the bulk of the work lies. You’ll need to transfer:

- Steering Column and Pedal Assembly

- Wiring Harness: This can be complex, often requiring extensions or modifications.

- Fuel Tank and Lines

- Brake Lines

- Seats, Roll Bar, Windshield Frame, Doors, Tailgate

- Dashboard Components, Gauges, Heater, Wiper Motor

Take pictures and label everything during disassembly of the old body to aid in reassembly.

5. Painting and Finishing

- Surface Preparation: Fiberglass bodies typically come with a gel coat. This needs to be thoroughly sanded, primed with an appropriate primer (often a 2-part epoxy primer), and block-sanded to achieve a perfectly smooth surface.

- Paint Application: Apply your chosen paint system. Many owners opt for durable coatings like bed liner on the interior for added protection and sound deadening.

6. Professional vs. DIY

While a DIY project is feasible, consider professional help if:

- You lack experience with complex vehicle disassembly/assembly.

- You don’t have the necessary tools or workspace.

- You’re uncomfortable with wiring or brake line work.

- You want a professional-grade paint finish.

Challenges and Solutions

While fiberglass bodies offer numerous advantages, it’s important to be aware of potential challenges and how to overcome them.

- Initial Cost: Fiberglass bodies generally have a higher upfront cost than a used, rusty steel body.

- Solution: View it as a long-term investment. The savings on rust repair, painting, and increased longevity often offset the initial expense.

- Fitment Variability: Even high-quality fiberglass bodies might require minor adjustments, shimming, or trimming for perfect fitment with existing components.

- Solution: Patience is key. Test fit everything repeatedly before final assembly. Don’t be afraid to use shims or carefully sand/trim small areas.

- Painting Preparation: The gel coat surface requires specific preparation and compatible primers for proper paint adhesion.

- Solution: Consult with a professional paint supplier or body shop for recommended primers and techniques. Follow manufacturer instructions precisely.

- Perception: Some purists prefer steel for "authenticity."

- Solution: Educate yourself and others on the practical benefits. The goal is a durable, long-lasting vehicle, not just a showpiece. For many, the ability to drive and enjoy a rust-free Jeep outweighs strict originality.

- Heat Transfer: Fiberglass can transmit engine and exhaust heat more readily than steel.

- Solution: Use sound deadening and heat shielding materials on the interior floor and firewall to insulate the cabin effectively.

Practical Advice and Actionable Insights

- Do Your Homework: Thoroughly research manufacturers and read reviews before committing to a purchase. Quality varies significantly.

- Plan Your Budget: Beyond the body itself, factor in shipping, paint, body mounts, new hardware, and any tools you might need.

- Inspect Thoroughly: Whether buying new or used, inspect the fiberglass body for defects, cracks, or warping.

- Consider the "Total Project": A new body is just one part of a restoration. Ensure your frame, drivetrain, and other components are in good condition.

- Seek Community Advice: Join online Jeep forums or local clubs. Many members have experience with fiberglass bodies and can offer invaluable tips and guidance.

- Patience Pays Off: This is a demanding but rewarding project. Don’t rush steps, especially test fitting and wiring.

Fiberglass Jeep Bodies For Sale: Estimated Price Guide

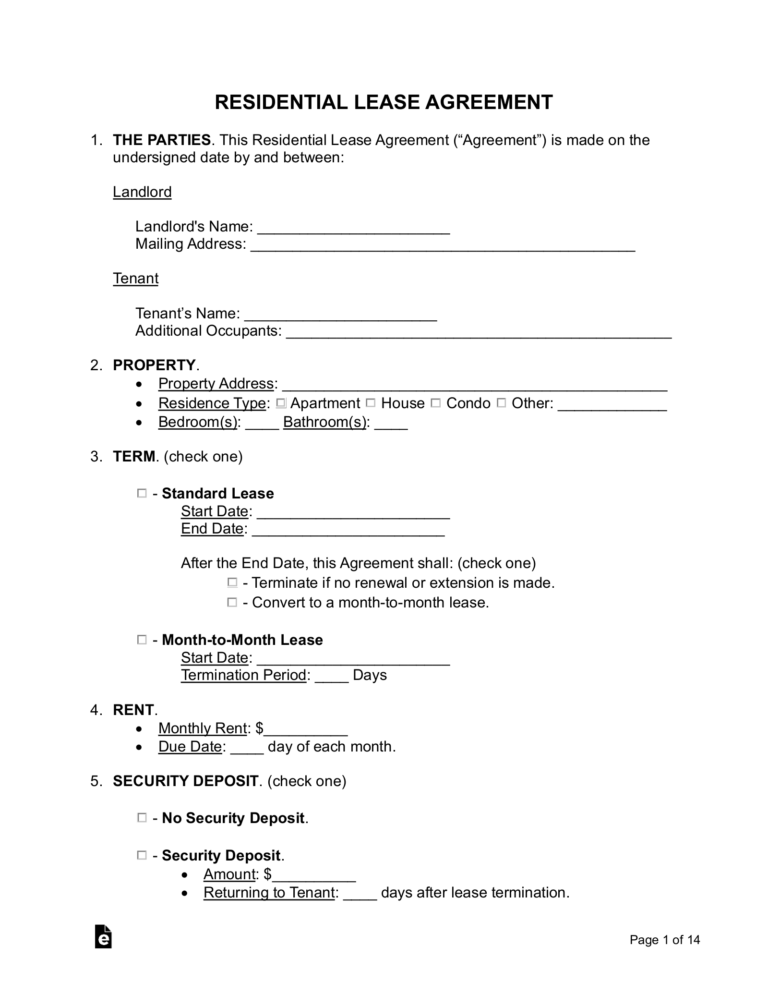

Please note: Prices for fiberglass Jeep bodies can vary significantly based on the manufacturer, the specific Jeep model, the completeness of the body (e.g., with or without integrated dash), and current material costs. The table below provides estimated ranges as of late 2023/early 2024 and should be used for general budgeting purposes only. Always obtain current quotes from specific manufacturers. Shipping costs are typically extra and can be substantial.

| Product Category | Jeep Model (Common) | Estimated Price Range (USD) | Notes / Typical Inclusions |

|---|---|---|---|

| Full Tub | CJ-2A, CJ-3A, CJ-3B | $3,500 – $6,500 | Bare tub, no doors/windshield frame, often with integrated dash. |

| Full Tub | CJ-5, CJ-7, CJ-8 | $4,500 – $8,000 | Bare tub, no doors/windshield frame, often with integrated dash and tailgate opening. |

| Full Tub | YJ Wrangler | $5,000 – $8,500 | Bare tub, no doors/windshield frame, may include some inner structure. |

| WWII MB/GPW Body | Willys MB, Ford GPW | $4,000 – $7,000 | Replica body, often includes firewall, inner fenders, some mounts. |

| Front Fender (Pair) | CJ, YJ | $400 – $800 | Left and Right front fenders. |

| Hood | CJ, YJ, MB/GPW | $300 – $600 | Bare hood panel. |

| Grille | CJ, MB/GPW | $200 – $450 | Front grille assembly. |

| Tailgate | CJ, YJ | $250 – $500 | Bare tailgate panel. |

| Dash Panel | CJ, YJ | $150 – $350 | Replacement dashboard panel. |

| Floor Pan (Section) | CJ, YJ | $100 – $250 | For localized repairs, not full floor. |

| Stretched Tub | Custom (CJ/YJ) | $6,000 – $10,000+ | Custom order, extended length. Price varies greatly by customization. |

Disclaimer: These prices are estimates only and do not include shipping, paint, hardware, or installation labor. Prices are subject to change without notice.

Frequently Asked Questions (FAQ)

Q1: Are fiberglass Jeep bodies street legal?

A1: Yes, absolutely. Fiberglass bodies are considered replacement parts and are legal for street use in all 50 states, provided the vehicle meets all other safety and registration requirements. You will typically transfer your original VIN plate from your old steel body to the new fiberglass one.

Q2: Do fiberglass bodies rust?

A2: No, fiberglass is a composite material that is completely impervious to rust and corrosion. This is one of their primary advantages over steel.

Q3: Are fiberglass bodies as strong as steel?

A3: Modern fiberglass composites are incredibly strong and durable, often surpassing steel in impact resistance and flexibility. While they might flex more than steel under extreme stress, they are less prone to permanent deformation, denting, or creasing. For most off-road and street applications, they are more than strong enough.

Q4: Can I use my original doors, windshield frame, and other components with a fiberglass body?

A4: Yes, reputable manufacturers design their fiberglass bodies to be direct replacements for the original steel bodies, meaning your original doors, windshield frame, tailgate, and other bolt-on components should fit. Minor adjustments or shimming may sometimes be necessary for perfect alignment.

Q5: How much lighter is a fiberglass Jeep body compared to steel?

A5: A full fiberglass tub can be 100 to 300 pounds lighter than its steel counterpart, depending on the specific Jeep model and the thickness/construction of the fiberglass. This significant weight reduction contributes to improved performance and fuel economy.

Q6: Is installing a fiberglass Jeep body a difficult DIY project?

A6: It’s a significant project that requires mechanical aptitude, patience, and some specialized tools, but it is achievable for a dedicated DIY enthusiast. The most challenging aspects often involve transferring the wiring harness, brake lines, and achieving perfect component alignment. If you’re unsure, professional installation is recommended.

Q7: Do fiberglass bodies come painted?

A7: Almost universally, fiberglass bodies are sold unpainted, typically with a smooth gel coat finish. They will require proper surface preparation (sanding, priming) and a full paint job after installation.

Q8: What about the VIN plate? How do I handle that with a new body?

A8: You will need to carefully remove the original VIN plate from your old steel body and securely attach it to the new fiberglass body in the same location (typically on the firewall or cowl). Check your local Department of Motor Vehicles (DMV) or equivalent agency for specific regulations regarding body swaps and VIN plate transfers in your state, as some may require an inspection.

Conclusion

The availability of Fiberglass Jeep Bodies For Sale has revolutionized the world of Jeep restoration and customization. They offer a compelling alternative to traditional steel, providing a permanent solution to rust, significant weight savings, enhanced durability, and simplified repair. While the initial investment might be higher, the long-term benefits in terms of reduced maintenance, increased longevity, and improved performance make fiberglass an increasingly attractive option for anyone looking to build a truly robust and enduring Jeep.

Whether you’re embarking on a full frame-off restoration of a classic CJ, building a lightweight off-road machine, or simply looking to replace a hopelessly rusted panel, fiberglass bodies empower you to create a vehicle that will stand the test of time, enduring the elements and countless adventures without succumbing to the dreaded brown plague. Embrace the future of Jeep ownership – a rust-free, lightweight, and incredibly durable ride awaits.