Fiberglass Jeep Body For Sale: The Ultimate Guide to Rust-Proofing Your Off-Road Dream

Fiberglass Jeep Body For Sale: The Ultimate Guide to Rust-Proofing Your Off-Road Dream jeeps.truckstrend.com

For generations, the Jeep has been synonymous with adventure, freedom, and rugged capability. From the iconic CJ series to the modern Wrangler, these vehicles have carved a unique niche in automotive history. However, one perennial adversary has plagued Jeep owners, particularly those cherishing older models: rust. The relentless march of corrosion can turn a beloved classic into a crumbling shell, leading to costly and often extensive repairs. This is where the fiberglass Jeep body for sale emerges as a revolutionary solution, offering a durable, rust-proof, and often lighter alternative to traditional steel.

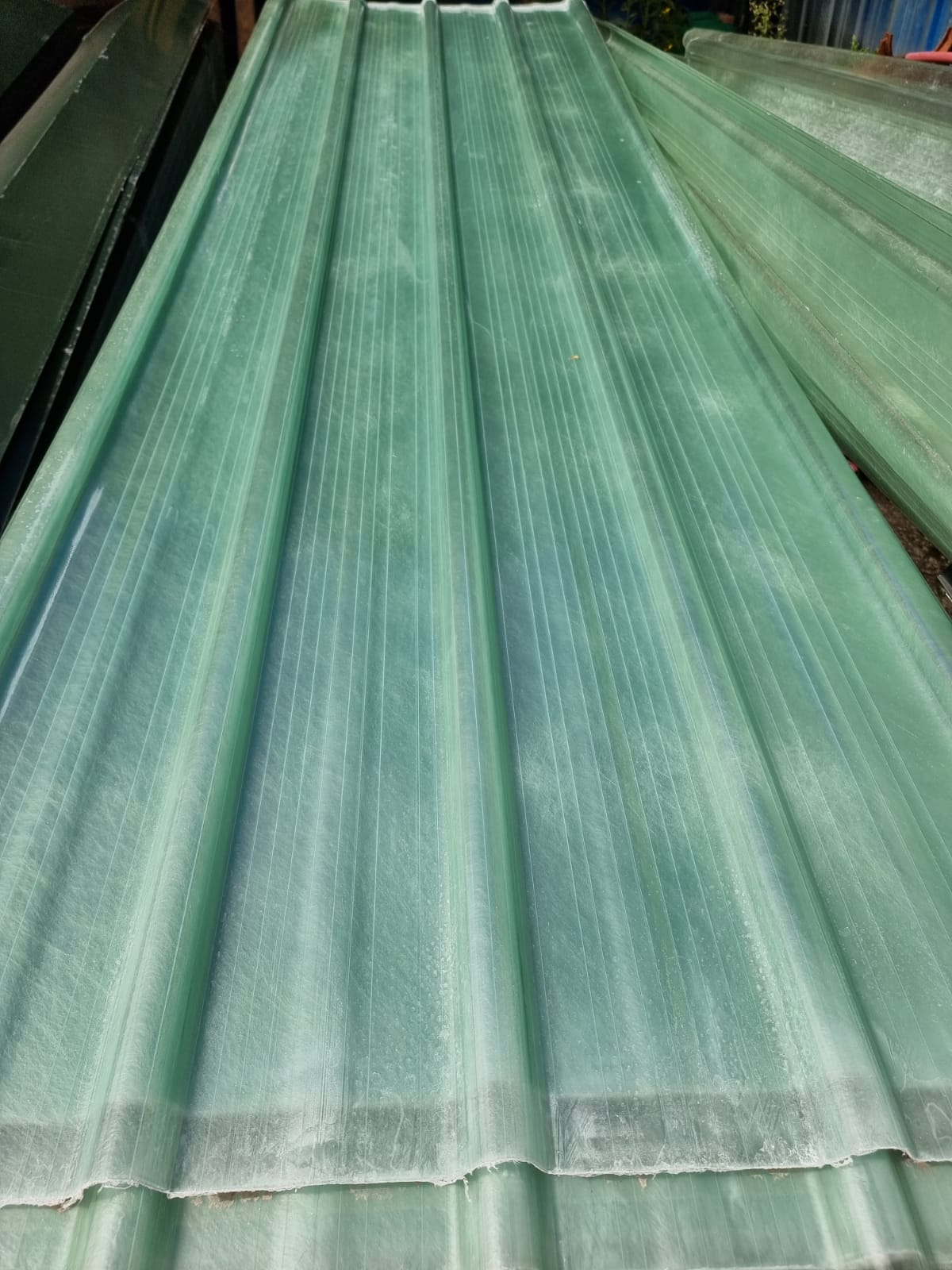

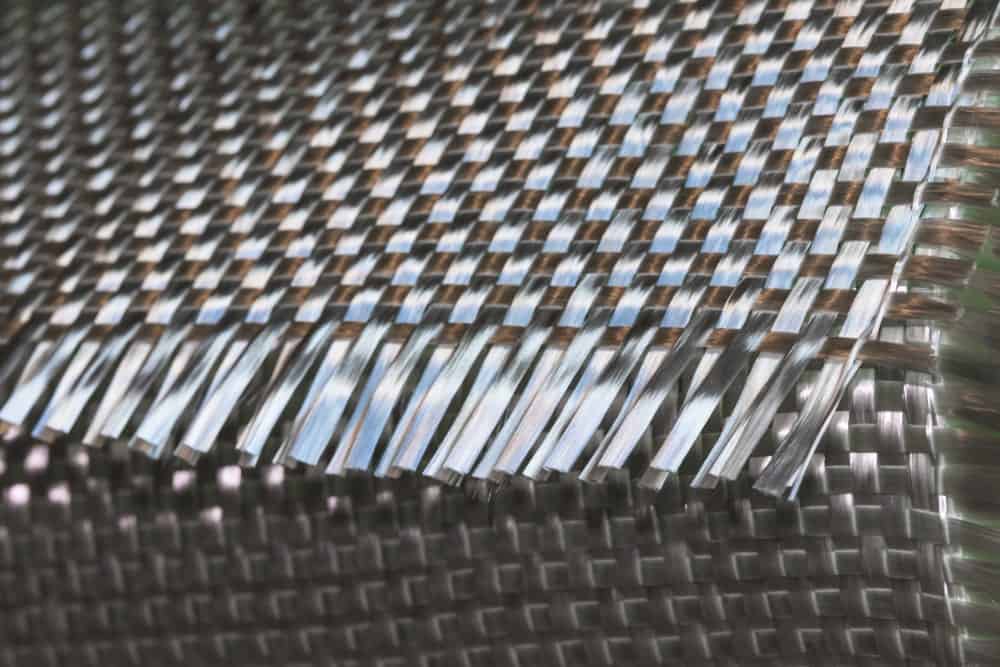

A fiberglass Jeep body is essentially a complete or partial replacement of your vehicle’s original steel shell, meticulously molded from fiberglass composites. These bodies are designed to perfectly fit your existing chassis and components, providing a seamless transition while eliminating the Achilles’ heel of steel: rust. Whether you’re undertaking a full restoration, building a custom off-road rig, or simply replacing a hopelessly corroded tub, investing in a fiberglass body can breathe new life into your Jeep, ensuring its longevity and enhancing its performance for years to come.

Fiberglass Jeep Body For Sale: The Ultimate Guide to Rust-Proofing Your Off-Road Dream

Why Choose a Fiberglass Jeep Body? The Undeniable Advantages

The decision to opt for a fiberglass body over a steel one is often driven by a compelling set of benefits that address the core challenges of owning and maintaining a vintage Jeep.

- Rust Immunity: This is, without a doubt, the primary and most significant advantage. Fiberglass is a composite material that does not contain iron or steel, making it completely impervious to rust and corrosion. For Jeeps, which are often exposed to harsh elements, road salt, mud, and water, this feature alone can save owners thousands in future repair costs and countless hours of frustration.

- Weight Reduction: Fiberglass is significantly lighter than steel. Replacing a heavy steel body tub with a fiberglass equivalent can shave hundreds of pounds off your vehicle’s curb weight. This weight reduction translates directly into improved fuel efficiency, better acceleration, enhanced braking performance, and reduced strain on suspension components. For serious off-roaders, a lighter vehicle can also mean better flotation over soft terrain and improved power-to-weight ratio.

- Durability and Impact Resistance: While steel might seem inherently stronger, fiberglass composites are incredibly robust and offer excellent impact resistance. Unlike steel, which can dent and crease upon impact, fiberglass tends to flex and spring back. In cases of severe impact, fiberglass can crack or shatter, but these damages are often easier and less costly to repair than complex steel bodywork. Modern fiberglass bodies are engineered with multiple layers and reinforcing materials to withstand the rigors of off-road abuse.

- Ease of Repair: Should your fiberglass body sustain damage, repairs are generally simpler and more accessible than traditional steel bodywork. Minor cracks or holes can often be patched using readily available fiberglass repair kits, requiring less specialized tools and welding expertise. This makes DIY repairs more feasible for the average enthusiast.

- Customization Potential: Fiberglass is a versatile material that lends itself well to modification. Drilling holes for accessories, cutting openings for custom components, or bonding additional pieces is often easier with fiberglass than with steel. This flexibility is a huge boon for builders looking to create truly unique custom Jeeps.

- Long-Term Cost-Effectiveness: While the initial outlay for a quality fiberglass body might be comparable to or even slightly higher than extensive steel rust repair, the long-term savings are substantial. Eliminating the recurring battle with rust means no more expensive body shop visits, no more chasing spreading corrosion, and a significantly extended lifespan for your vehicle’s body.

Types of Fiberglass Jeep Bodies Available

The market for fiberglass Jeep bodies is diverse, catering to various models and restoration needs. Understanding the different types available is crucial for making an informed purchase.

- Full Body Tubs: These are the most comprehensive options, typically including the entire tub (floor, inner and outer fenders, firewall, cowl, rear bulkhead, and often the tailgate opening). Some manufacturers also offer matching fiberglass hoods, grilles, and front fenders as part of a complete kit. These are ideal for ground-up restorations or when the original steel tub is beyond repair.

- Individual Panels: For those whose Jeeps only suffer from localized rust or damage, individual fiberglass panels are available. Common items include:

- Fenders: Front and rear, often available in stock width or wider "flare" styles for larger tires.

- Hoods: Direct replacements for factory steel hoods.

- Grilles: Replicas of original Jeep grilles.

- Tailgates: Complete fiberglass tailgate assemblies.

- Hardtops: Fiberglass hardtops are popular for their weather resistance and sound dampening.

- Specific Jeep Models: The vast majority of fiberglass body offerings target the classic Jeep CJ series (CJ-5, CJ-7, CJ-8 Scrambler) and the early Wrangler YJ models. This is because these vehicles are older and more prone to severe rust. While less common, some manufacturers also produce fiberglass components for TJ Wranglers. Modern JK/JL Wranglers typically do not have aftermarket fiberglass body tubs due to their more complex unibody-like construction and robust factory rust protection.

- Replica vs. Custom Designs: Most fiberglass bodies are direct replicas of the original steel designs, ensuring a factory-like appearance and fitment. However, some manufacturers also offer subtly modified or custom designs, such as extended tubs for more legroom or integrated fender flares, catering to specific custom build preferences.

What to Look For When Buying a Fiberglass Jeep Body

Purchasing a fiberglass Jeep body is a significant investment. Careful consideration of several factors will ensure you get a high-quality product that meets your expectations.

- Quality of Construction: Inspect the fiberglass weave and thickness. High-quality bodies will have a consistent, uniform thickness and a smooth gel coat finish, indicating good mold quality and proper resin saturation. Avoid bodies with visible air bubbles, uneven surfaces, or flimsy spots, as these can indicate manufacturing defects or insufficient material.

- Fitment and Accuracy: Research the manufacturer’s reputation for accurate fitment. The body should align perfectly with your existing chassis mounting points, door hinges, and other components. Some bodies come with pre-drilled holes, while others require drilling during installation. Pre-drilled holes should be precise and well-aligned.

- Manufacturer Reputation and Warranty: Choose a reputable manufacturer with a proven track record. Read reviews, check forums, and inquire about their warranty policy. A good warranty demonstrates the manufacturer’s confidence in their product’s durability and quality.

- Completeness of the Kit: Understand exactly what is included in the "body" you are purchasing. Does it include the tailgate, hood, or front fenders? Are specific brackets or hardware included? Knowing this upfront will help you budget for additional parts.

- Shipping and Handling: Fiberglass bodies are large and fragile. Inquire about shipping costs, methods, and insurance. Inspect the body thoroughly upon arrival for any shipping damage before signing off on the delivery.

- Surface Finish: Most fiberglass bodies come with a smooth, paintable gel coat finish. However, they will still require proper preparation, sanding, and priming before painting to achieve a showroom-quality finish.

The Installation Process: A Step-by-Step Overview

Installing a fiberglass Jeep body is a substantial project that requires mechanical aptitude, patience, and attention to detail. While it can be a rewarding DIY endeavor, professional installation is also an option for those less comfortable with major automotive work.

- Preparation: The first step involves meticulously disassembling your old Jeep body. This includes removing all interior components, wiring harnesses, fuel lines, brake lines, steering column, dashboard, seats, and any other items attached to the tub. The old body is then unbolted from the frame and removed. The frame should be thoroughly inspected for rust, damage, or bends, and cleaned or repaired as needed.

- Test Fit: This is a crucial step. Before permanently mounting, carefully set the new fiberglass body onto the frame. Check for proper alignment with the frame mounting points, door openings, and other critical areas. Make any necessary adjustments or shims to ensure a perfect fit.

- Mounting: Secure the new fiberglass body to the frame using new body mounts and hardware. It’s essential to use appropriate hardware and ensure even tightening to prevent stress points on the fiberglass.

- Component Transfer: This is often the most time-consuming part. All the components removed from the old body – wiring, fuel lines, brake lines, steering column, pedal assembly, heater box, dash, seats, and roll bar – must be carefully transferred and reinstalled into the new fiberglass tub. This often involves drilling new holes for mounting brackets and routing lines.

- Finishing: Once all components are reinstalled, the body is ready for final paint and finishing. This involves proper surface preparation, priming, and several coats of automotive paint.

Challenges and Solutions

While fiberglass bodies offer numerous advantages, it’s important to be aware of potential challenges:

- Initial Cost: A high-quality fiberglass body tub can be a significant upfront expense, often ranging from $2,000 to $5,000 or more, depending on the model and completeness. However, this should be weighed against the long-term savings on rust repair.

- Flexibility vs. Rigidity: Some perceive fiberglass as "flimsy." While it does have more flex than steel, well-engineered fiberglass bodies are designed to be strong and durable. Proper mounting and reinforcement (where provided by the manufacturer) are key to preventing issues.

- Painting Differences: Fiberglass requires specific primers and surface preparation techniques compared to steel to ensure proper paint adhesion and a smooth finish. Consult with a professional painter or follow manufacturer recommendations.

- Originality Concerns: For purist collectors, a fiberglass body might detract from the vehicle’s "originality." However, for most enthusiasts building a driver or off-road rig, the practical benefits far outweigh this concern.

- Availability for Newer Models: Fiberglass body tubs are less common for newer Jeep models (JK/JL) due to their factory rust protection and more complex construction.

Practical Advice and Actionable Insights

- Research Extensively: Before purchasing, spend time researching different manufacturers, reading reviews, and looking at photos of completed projects.

- Inspect Upon Arrival: Thoroughly inspect the fiberglass body for any damage immediately upon delivery. Document any issues with photos and contact the shipper/seller promptly.

- Consider Your Skill Level: Be realistic about your mechanical abilities. If you’re not comfortable with major automotive disassembly and reassembly, factor in the cost of professional installation.

- Budget for Everything: Remember that the body tub is just one part of the equation. Budget for shipping, paint, new body mounts, hardware, and potentially new wiring or brake lines if your old ones are deteriorated.

- Join Online Communities: Jeep forums and Facebook groups are invaluable resources. You can find advice, tips, and even recommendations for manufacturers from experienced owners.

Fiberglass Jeep Body Price Table (Estimates)

Please note that prices can vary significantly based on the manufacturer, quality, specific Jeep model, and completeness of the kit. These are general estimates.

| Product Type | Jeep Model (Common) | Estimated Price Range (USD) | Notes |

|---|---|---|---|

| Full Body Tub | CJ-5, CJ-7, YJ | $2,500 – $5,500+ | Typically includes firewall, cowl, inner/outer fenders. May or may not include tailgate/hood. |

| Front Fenders (Pair) | CJ-5, CJ-7, YJ | $300 – $600 | Available in stock width or wide-flare designs. |

| Hood | CJ-5, CJ-7, YJ | $300 – $550 | Direct replacement for steel hood. |

| Grille | CJ-5, CJ-7, YJ | $200 – $400 | Replicates original steel grille. |

| Tailgate | CJ-7, YJ | $250 – $450 | Complete fiberglass tailgate assembly. |

| Hardtop (Full) | CJ-7, YJ, TJ | $1,500 – $3,000+ | Can be 1-piece or 2-piece, often includes windows. |

| Half Doors (Pair) | CJ-7, YJ, TJ | $400 – $700 | Fiberglass construction for lighter weight. |

| Tub & Fender Combo | CJ-7, YJ | $3,000 – $6,000+ | Often sold as a package for a more complete front-end replacement. |

Disclaimer: These prices are estimates and can change based on market conditions, material costs, manufacturer, and specific features. Always get a direct quote from the seller.

Frequently Asked Questions (FAQ)

Q1: Are fiberglass Jeep bodies street legal?

A1: Yes, in most jurisdictions, fiberglass replacement bodies are perfectly street legal as long as they meet all safety requirements (lights, mirrors, etc.) and are properly registered with your vehicle’s VIN. They are considered replacement parts, not a new vehicle.

Q2: Do fiberglass bodies rust?

A2: No, fiberglass itself is a composite material made from glass fibers and resin, which are completely impervious to rust and corrosion. This is their primary advantage over steel.

Q3: Are fiberglass bodies as strong as steel?

A3: While steel has higher tensile strength, well-constructed fiberglass bodies are incredibly durable and offer excellent impact resistance. They flex rather than dent, and damage is often easier to repair. For off-road use, many find them robust enough for severe abuse.

Q4: Can I paint a fiberglass Jeep body myself?

A4: Yes, but it requires proper preparation. The gel coat needs to be scuffed, cleaned, and often primed with a specialized primer designed for fiberglass or composites to ensure proper adhesion. For best results, professional painting is recommended.

Q5: How long do fiberglass Jeep bodies last?

A5: With proper care and maintenance, a high-quality fiberglass body can last indefinitely, far outliving a steel body in terms of rust resistance. The material itself is highly stable and resistant to environmental degradation.

Q6: Do fiberglass bodies come with doors, hoods, and tailgates?

A6: It varies by manufacturer and specific product. Some full body tubs may include the tailgate opening and hinge points but require you to transfer your original tailgate or purchase a fiberglass replacement. Hoods and front fenders are almost always sold separately or as part of a more comprehensive "kit." Always confirm what is included before purchasing.

Q7: Are fiberglass bodies heavier or lighter than steel?

A7: Fiberglass bodies are significantly lighter than their steel counterparts. This weight reduction offers benefits in fuel economy, performance, and reduced stress on suspension components.

Conclusion

The appeal of a fiberglass Jeep body for sale extends far beyond simply replacing a rusty shell. It represents an upgrade, a long-term investment in your vehicle’s future, and a definitive end to the battle against corrosion. By offering unparalleled rust immunity, significant weight reduction, and surprising durability, fiberglass bodies empower Jeep enthusiasts to restore, customize, and enjoy their beloved vehicles for decades to come, ensuring that the spirit of adventure continues unhindered by the insidious creep of rust. Whether you’re bringing a vintage CJ back to life or building the ultimate off-road machine, a fiberglass body is a smart, durable, and increasingly popular choice that truly lets your Jeep live up to its rugged legacy.