Fiberglass Jeep Body For Sale: Your Ultimate Guide to Rust-Free Restoration and Customization

Fiberglass Jeep Body For Sale: Your Ultimate Guide to Rust-Free Restoration and Customization jeeps.truckstrend.com

For generations, the Jeep has stood as an icon of rugged adventure, off-road prowess, and timeless American design. From the classic Willys MB to the ubiquitous CJ and the modern Wrangler, the spirit of the Jeep has captivated enthusiasts worldwide. However, time, harsh weather, and the inevitable enemy – rust – often take their toll on these beloved vehicles. This is where the fiberglass Jeep body for sale emerges as a revolutionary solution, offering a new lease on life for cherished rigs and a solid foundation for custom builds.

A fiberglass Jeep body is essentially a lightweight, rust-proof, and often more durable alternative to the original steel body panels. It’s a complete or partial replacement for your Jeep’s sheet metal, meticulously molded from composite materials to replicate the original contours and dimensions. Whether you’re embarking on a full frame-off restoration, seeking to shed some weight for performance, or simply want to escape the endless battle against corrosion, investing in a fiberglass body can transform your Jeep experience from a rust-bucket nightmare into a pristine, long-lasting dream machine. This comprehensive guide will delve into every aspect of fiberglass Jeep bodies, from their undeniable advantages to practical purchasing advice and installation tips, ensuring you’re well-equipped to make an informed decision.

Fiberglass Jeep Body For Sale: Your Ultimate Guide to Rust-Free Restoration and Customization

Why Choose Fiberglass? The Undeniable Advantages

The appeal of a fiberglass Jeep body extends far beyond mere aesthetics. It offers a multitude of practical benefits that address common issues faced by Jeep owners, particularly those with vintage or heavily used models.

Rust Resistance: The Ultimate Solution

This is arguably the most significant advantage. Unlike steel, fiberglass does not rust, corrode, or degrade when exposed to moisture, salt, or road chemicals. For Jeeps that spend their lives off-road, near the coast, or in regions with harsh winters, a fiberglass body eliminates the perennial battle against structural decay and unsightly rust bubbles, ensuring your investment lasts for decades without the need for constant patch-ups.

Weight Savings: Enhanced Performance and Efficiency

Fiberglass is significantly lighter than steel. Replacing a heavy steel tub with a fiberglass equivalent can shave hundreds of pounds off your Jeep’s overall weight. This reduction translates directly into improved fuel economy, better acceleration, reduced strain on suspension components, and enhanced off-road performance due particularly to a lower center of gravity and increased power-to-weight ratio. For rock crawlers and racers, this weight advantage can be a game-changer.

Durability and Impact Resistance

While often perceived as fragile, modern fiberglass composites are incredibly strong and flexible. They can absorb impacts and flex without creasing or denting like steel. In the event of an off-road mishap or minor collision, fiberglass often resists significant damage and, if damaged, is typically easier to repair than heavily crumpled steel. Its inherent flexibility helps dissipate impact energy, making it a robust choice for adventurous drivers.

.jpg)

Ease of Repair

Should a fiberglass body sustain damage, repairs are generally simpler and more straightforward than welding and bodywork on steel. Using readily available fiberglass repair kits, epoxy resins, and sanding tools, many minor cracks or punctures can be fixed by a DIY enthusiast. This reduces repair costs and downtime, getting your Jeep back on the trail faster.

Cost-Effectiveness in the Long Run

While the initial outlay for a fiberglass body might seem substantial, consider the long-term savings. Eliminating costly rust repairs, body filler, welding, and frequent repainting due to corrosion means significant savings over the lifespan of your vehicle. Furthermore, the increased longevity and structural integrity of a fiberglass body can enhance your Jeep’s resale value.

Availability for Older Models

For vintage Jeeps like the CJ series, finding rust-free original steel bodies is becoming increasingly difficult and expensive. Fiberglass manufacturers specialize in recreating these classic bodies with precision, making restoration projects feasible and accessible for a wider range of enthusiasts who might otherwise abandon their dreams due to lack of parts.

Types of Fiberglass Jeep Bodies Available

The market for fiberglass Jeep bodies offers a variety of options to suit different needs and project scopes. Understanding these categories is crucial for making the right purchase.

Full Replacement Tubs

These are complete, one-piece body shells designed to mount directly onto your existing frame. They typically include the floor, inner and outer fenders, firewall, and rear bed area, essentially everything from the cowl back. Full tubs are ideal for frame-off restorations where the original body is severely rusted or damaged beyond repair. They save considerable time and effort compared to piecing together individual panels.

Individual Body Panels

For those needing to replace only specific damaged or rusted sections, manufacturers also offer individual fiberglass panels. These include:

- Fenders: Front and rear, often available in original style or wider "flare" versions for larger tires.

- Hoods: Standard flat hoods or custom designs with scoops.

- Grilles: Replicas of iconic Jeep grille designs.

- Tailgates: Rust-proof replacements for often-damaged rear gates.

- Windshield Frames: Crucial for rust-prone areas.

- Door Skins/Full Doors: Although less common for full doors, some manufacturers offer fiberglass alternatives or skins.

Model-Specific Applications

Fiberglass bodies are primarily available for classic and older Jeep models where rust is a prevalent issue and original bodies are scarce. The most common applications include:

- Jeep CJ Series (CJ-2A, CJ-3A, CJ-3B, CJ-5, CJ-6, CJ-7, CJ-8 Scrambler): These are the most popular candidates for fiberglass bodies due to their age and susceptibility to rust.

- Jeep YJ Wrangler (1987-1995): Also prone to rust, YJ fiberglass bodies are readily available.

- Jeep TJ Wrangler (1997-2006): While generally more rust-resistant than CJs/YJs, TJ fiberglass bodies are still produced for custom builds or severe rust cases.

- Custom/Aftermarket Designs: Some manufacturers offer unique fiberglass body designs that deviate from original styling, providing a custom look.

Raw vs. Finished State

Most fiberglass bodies are sold in a raw, gel-coat finish. This typically means they come out of the mold with a smooth, but unpainted, outer surface. They will require sanding, primer application, and painting to match your desired color. Some premium manufacturers might offer pre-primed options, but a professional paint job is almost always necessary for a finished look.

Key Considerations Before Buying

Purchasing a fiberglass Jeep body is a significant investment. Careful consideration of several factors will ensure you get a high-quality product that meets your expectations.

Quality and Manufacturer Reputation

Not all fiberglass is created equal. The quality of materials, the precision of the molds, and the craftsmanship of the manufacturer vary widely. Research reputable brands known for their durable products and accurate fitment. Look for companies with positive reviews, good customer service, and a history of producing high-quality Jeep components. Brands like Aqualu (aluminum, but often cross-shopped for rust-free), Omix-ADA (though they mostly deal in steel, some fiberglass parts), and various specialized fiberglass fabricators are worth investigating.

Fitment and Alignment

This is paramount. A poorly molded body will lead to endless frustration during installation, with misaligned bolt holes, uneven panel gaps, and difficulty mounting doors or windshields. Seek out manufacturers who emphasize precision molding and offer guarantees on fitment. Reading reviews from previous buyers regarding their installation experiences is highly recommended.

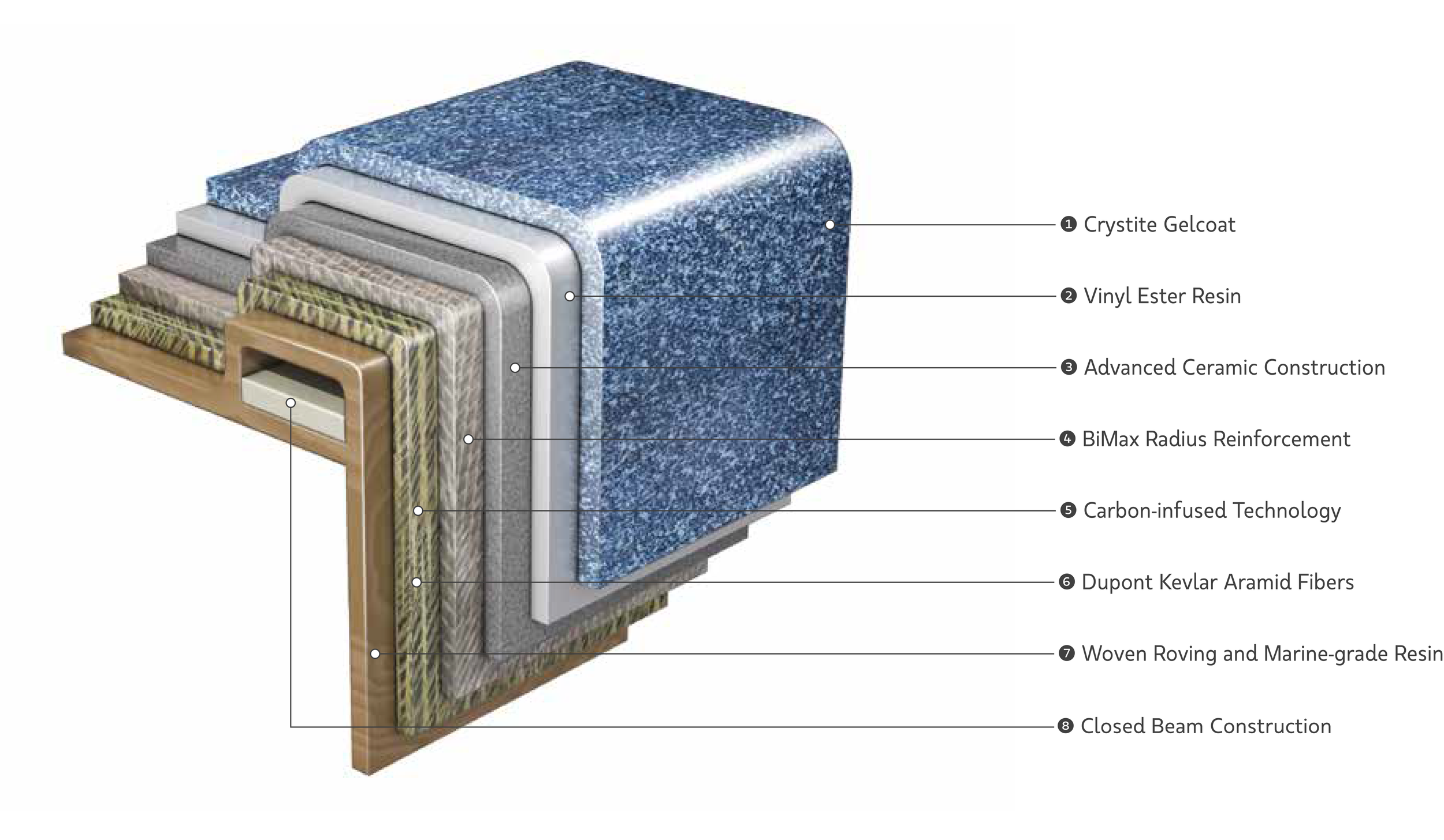

Material Thickness and Reinforcement

A good quality fiberglass body will have appropriate material thickness (usually measured in layers or ounces per square foot) and strategically placed internal reinforcements in high-stress areas (e.g., around body mounts, door hinges, and seat mounts). Thicker sections and well-integrated bracing contribute to structural integrity and longevity. Inquire about the construction methods and reinforcement points.

Preparation Required

Understand what state the body will arrive in. Most will require extensive prep work, including sanding, potentially filling minor imperfections, applying a high-build primer, and then a final paint job. Factor in the cost and time for this finishing work, whether you plan to do it yourself or hire a professional.

Shipping and Handling

Fiberglass bodies are large, often fragile items. Shipping costs can be substantial, and there’s a risk of damage in transit. Ensure the seller uses robust crating and reliable freight services. Always thoroughly inspect the body upon arrival before signing off on the delivery, documenting any damage with photos and immediately notifying the shipping company and seller.

Legal and Registration Implications

For most body-off restorations where you’re simply replacing the existing body on the original frame, there are typically no major legal or registration hurdles. The vehicle’s VIN is usually stamped on the frame, not the body. However, if you’re building a "new" vehicle from scratch or using a non-original frame, check your local Department of Motor Vehicles (DMV) regulations regarding "kit car" or "assembled vehicle" registration, as rules vary by state/country.

Budget Beyond the Body

Remember that the cost of the fiberglass body is just one component. You’ll also need to budget for:

- Shipping costs.

- Paint and bodywork (materials or professional service).

- New body mount hardware, bolts, and possibly wiring harnesses.

- Sound deadening and interior insulation.

- Any additional accessories or upgrades you plan to make during the build.

Installation Process: A General Overview

Installing a fiberglass Jeep body is a significant undertaking, often requiring a frame-off approach. While specific steps vary by model and manufacturer, here’s a general overview:

-

Preparation and Disassembly:

- Thoroughly document your existing Jeep with photos and notes, especially wiring and component locations.

- Disconnect all electrical, fuel, brake, and steering lines.

- Carefully remove all components from the old body: seats, dashboard, steering column, roll bar, wiring harness, fuel tank, etc. Label everything!

- Unbolt the old steel body from the frame. This is often the most challenging part due to rusted bolts.

- Lift and remove the old body. This typically requires multiple people or a hoist.

-

Frame Inspection and Preparation:

- With the body off, this is the perfect opportunity to inspect your Jeep’s frame for rust, cracks, or damage. Repair or reinforce as needed.

- Clean and paint the frame to protect it and give it a fresh look.

- Install new body mount bushings and hardware.

-

Mounting the Fiberglass Tub:

- Carefully lower the new fiberglass tub onto the frame, aligning it with the body mounts.

- Secure the tub to the frame using new, appropriate hardware. Do not overtighten, as fiberglass can crack under excessive stress. Use large washers to distribute pressure.

- Ensure the tub is level and square on the frame.

-

Panel Alignment and Component Transfer:

- If you purchased individual panels (fenders, hood, grille), carefully align and temporarily bolt them into place. Ensure consistent panel gaps.

- Begin transferring components from the old body to the new one: dashboard, wiring harness, steering column, brake and clutch pedals, fuel tank, and brake lines.

- Many fiberglass bodies come with pre-drilled holes, but some may require drilling. Use a template or carefully measure and drill pilot holes before enlarging.

-

Finishing Touches:

- Install doors, windshield frame, and tailgate, ensuring proper alignment and hinge operation.

- Perform any necessary bodywork (sanding, minor filling) on the fiberglass surface.

- Apply primer and then paint the body to your desired color. This is a critical step for longevity and appearance.

- Reinstall seats, roll bar, and other interior components.

Practical Advice: Take your time. This is not a weekend project. Recruit help when lifting heavy components. Label every wire and bolt. Invest in a good shop manual for your specific Jeep model. Consider using sound deadening material on the inside of the fiberglass tub for a quieter ride.

Tips for Sourcing and Purchasing

Finding the right fiberglass Jeep body involves a bit of research and due diligence.

- Specialized Online Retailers: Many online stores specialize in Jeep parts and restorations. They often carry fiberglass bodies from various manufacturers. Examples include Quadratec, Morris 4×4, and other dedicated Jeep aftermarket sites.

- Direct from Manufacturers: Some fiberglass body manufacturers sell directly to consumers. This can sometimes offer better pricing or direct access to technical support.

- Online Forums and Classifieds: Jeep enthusiast forums, Facebook groups, and classified sites (like Craigslist or eBay) can sometimes yield used or partially completed fiberglass bodies for a lower price, though these carry higher risks regarding condition and quality.

- Local Fabrication Shops: In some areas, custom composite fabrication shops might be able to create or source a body for you, though this is less common for full bodies and more for custom panels.

- Check Reviews and Forums: Before committing, search for reviews of specific manufacturers and models of fiberglass bodies. Jeep forums are invaluable resources for real-world experiences and recommendations.

- Ask Detailed Questions: Don’t hesitate to ask the seller or manufacturer about material thickness, reinforcement, warranty, return policy, and shipping procedures. Request detailed photos if buying online.

Potential Challenges and Solutions

While fiberglass bodies offer many benefits, there are potential challenges to be aware of.

- Fitment Issues: Even with reputable brands, minor fitment issues can arise due to manufacturing tolerances or variations in your frame.

- Solution: Patience, careful alignment, shimming body mounts, and minor trimming with a grinder or Dremel are often required. Don’t force anything.

- Finishing Work: Achieving a flawless paint finish on fiberglass requires skill and proper preparation.

- Solution: Budget for professional painting if you’re not experienced in bodywork and painting. If DIY, invest in quality materials and follow proper sanding and priming techniques.

- Shipping Damage: The large size and somewhat fragile nature of fiberglass can lead to shipping damage.

- Solution: Inspect the package thoroughly upon arrival before signing for it. Document any damage with photos and immediately file a claim with the shipping company and notify the seller.

- Cost Overruns: Unexpected expenses can arise during a major restoration.

- Solution: Create a detailed budget and add a 10-20% contingency fund for unforeseen costs.

- Lack of Pre-Drilled Holes: Some bodies may come with minimal or no pre-drilled holes.

- Solution: Use the old body or original components as templates for accurate drilling. Start with small pilot holes and gradually enlarge them.

Fiberglass Jeep Body Price Table (Estimated Ranges)

Please note: Prices are highly variable based on manufacturer, quality, specific Jeep model (CJ, YJ, TJ), and current market conditions. These are general estimates for new, unpainted fiberglass bodies/panels. Shipping costs are not included and can add hundreds to over a thousand dollars depending on location.

| Product Type | Jeep Model Application (Common) | Estimated Price Range (USD) | Notes |

|---|---|---|---|

| Full Replacement Tub | CJ-5, CJ-7, YJ Wrangler | $3,500 – $7,000 | Complete body shell, requires finishing/paint. |

| Full Replacement Tub | CJ-8 Scrambler | $5,000 – $9,000 | Longer wheelbase, often higher demand. |

| Front Fenders (Pair) | CJ, YJ, TJ | $400 – $900 | Can be stock width or wider for larger tires. |

| Hood | CJ, YJ, TJ | $300 – $700 | Standard or custom designs available. |

| Grille | CJ, YJ | $150 – $400 | Iconic 7-slot design. |

| Tailgate | CJ, YJ | $200 – $500 | Rust-prone area, popular replacement. |

| Windshield Frame | CJ, YJ | $300 – $700 | Often a critical rust point. |

| Inner Fender Wells (Pair) | CJ, YJ, TJ | $150 – $350 | Useful for custom builds or rust repair. |

| Complete Body Kit | (Tub + Fenders + Hood + Grille) | $4,500 – $10,000+ | Often a package deal from manufacturers. |

Prices are for the fiberglass components only and do not include shipping, paint, labor, or installation hardware.

Frequently Asked Questions (FAQ) about Fiberglass Jeep Bodies

Q1: Is fiberglass as strong as steel?

A1: Modern fiberglass composites are incredibly strong and durable, often surpassing steel in specific properties like impact resistance and flexibility. While steel is generally stiffer, fiberglass can flex and absorb impacts without denting or creasing. For most typical driving and off-road conditions, a quality fiberglass body is more than strong enough and offers superior rust resistance.

Q2: How much weight does a fiberglass body save?

A2: The exact weight savings vary by model and original steel condition, but replacing a full steel tub with fiberglass can typically save between 150 to 300 pounds. This significant reduction improves performance, fuel economy, and reduces strain on other components.

Q3: Can I paint a fiberglass body myself?

A3: Yes, but it requires proper preparation and painting techniques. The fiberglass surface needs to be thoroughly cleaned, sanded, and primed with an appropriate automotive-grade primer designed for composites. For a professional, durable, and aesthetically pleasing finish, hiring an experienced auto body painter is recommended unless you have significant prior experience.

Q4: Do fiberglass bodies rust?

A4: No, fiberglass itself does not rust, corrode, or rot. This is its primary advantage over steel, making it an excellent choice for longevity, especially in harsh environments.

Q5: Are fiberglass Jeep bodies legal?

A5: Yes, replacing your Jeep’s body with a fiberglass equivalent is generally legal, as the vehicle’s VIN is typically stamped on the frame, not the body. It’s considered a body replacement or restoration. However, if you are building a vehicle from scratch using a new frame and fiberglass body, check your local DMV regulations regarding "kit car" or "assembled vehicle" registration, as rules can vary.

Q6: What is the typical lifespan of a fiberglass Jeep body?

A6: With proper care, a quality fiberglass Jeep body can last for many decades, potentially outliving the frame it sits on. Its resistance to rust and degradation ensures a much longer lifespan than steel bodies in corrosive environments.

Q7: Do fiberglass bodies come pre-drilled for components?

A7: This varies by manufacturer. Many reputable manufacturers will pre-drill common mounting holes for things like the dashboard, steering column, and body mounts to aid installation. However, it’s common to find that some holes may still need to be drilled or enlarged for a perfect fit, as component tolerances can vary. Always check with the manufacturer before purchasing.

Conclusion

The decision to purchase a fiberglass Jeep body for sale is more than just a repair; it’s an investment in the future of your beloved vehicle. It’s an opportunity to escape the relentless cycle of rust, reduce weight for enhanced performance, and create a truly custom, long-lasting machine. While the installation demands patience and skill, the rewards are immense: a virtually indestructible, lightweight, and stunningly restored or customized Jeep that will turn heads on the street and conquer trails with renewed vigor. By understanding the types available, considering key factors before purchase, and approaching the installation with informed preparation, you can transform your Jeep dreams into a tangible, rust-free reality, ensuring countless more years of open-air adventure.