Flood Damaged Jeep Parts For Sale: A Comprehensive Guide for the Savvy Buyer

Flood Damaged Jeep Parts For Sale: A Comprehensive Guide for the Savvy Buyer jeeps.truckstrend.com

The allure of a Jeep is undeniable – its rugged capability, iconic design, and limitless customization potential make it a beloved vehicle worldwide. However, maintaining or upgrading a Jeep can be an expensive endeavor, especially when sourcing new or even quality used parts. This is where the intriguing, yet often misunderstood, market of "Flood Damaged Jeep Parts For Sale" enters the picture. Far from being scrap, these parts, salvaged from vehicles affected by floods, can represent a significant cost-saving opportunity for the informed buyer.

This comprehensive guide will delve into the world of flood-damaged Jeep parts, exploring their potential benefits, inherent risks, and crucial considerations for anyone looking to tap into this unique market. Whether you’re a seasoned mechanic, a dedicated DIY enthusiast, or someone building a custom off-road rig on a budget, understanding the nuances of these parts is essential to making a smart, cost-effective decision.

Flood Damaged Jeep Parts For Sale: A Comprehensive Guide for the Savvy Buyer

Understanding Flood Damage: What It Means for Jeep Parts

Before diving into the buying process, it’s vital to grasp the various ways floodwaters can impact vehicle components. Not all "flood damage" is created equal, and the type and severity of the damage dictate a part’s salvageability and the effort required for restoration.

- Water Ingress and Contamination: The most obvious impact. Water, often mixed with silt, mud, chemicals, and even raw sewage, can penetrate every crevice. This leads to:

- Corrosion: Rust is the primary enemy. Metals exposed to water and air will quickly oxidize, weakening structural integrity and seizing moving parts. Electrical connectors are particularly vulnerable.

- Silt/Mud Residue: Fine particles can get into bearings, seals, electrical contacts, and internal engine components, causing abrasive wear and blockages.

- Fluid Contamination: Engine oil, transmission fluid, differential fluid, and brake fluid can become contaminated with water, leading to lubrication failure and severe damage to internal components.

- Electrical System Compromise: Water and electricity are a dangerous mix.

- Short Circuits: Immediate damage can occur when power is applied to wet circuits.

- Long-Term Corrosion: Even after drying, residual moisture can cause slow, insidious corrosion on wiring, connectors, modules (ECUs, BCMs), and sensors, leading to intermittent failures or complete system breakdowns.

- Biological Growth: Mold, mildew, and bacteria thrive in damp, enclosed environments. This primarily affects interior components, leading to unpleasant odors and potential health hazards.

- Structural Weakness (Rare but Possible): While less common for parts themselves, extreme flood forces (e.g., strong currents, debris impact) could potentially warp or damage larger structural components like frames or axle housings, though this is usually visible.

Understanding these damage types helps in assessing a part’s true condition and its potential for rehabilitation.

The Allure of Discounted Parts: Why Buy Flood-Damaged?

Despite the inherent risks, there are compelling reasons why buyers seek out flood-damaged Jeep parts:

- Significant Cost Savings: This is the primary driver. Flood-damaged parts are often sold at a fraction of the cost of new OEM, aftermarket, or even standard used parts. Discounts can range from 50% to over 90% depending on the part and the extent of the damage.

- Availability of Rare or Discontinued Parts: For owners of older or less common Jeep models, finding specific parts can be a challenge. Flood-damaged vehicles, even those totaled by insurance, might contain the exact component needed, offering a lifeline for a restoration project.

- Ideal for Project Vehicles and Off-Road Rigs: If you’re building a dedicated off-road machine, a rock crawler, or a custom show vehicle, aesthetics might not be your top priority, or you might plan to heavily modify/rebuild parts anyway. A flood-damaged axle, for example, can be completely disassembled, cleaned, fitted with new gears and lockers, and emerge as a robust component at a lower initial cost.

- Eco-Friendly Recycling: Purchasing and rehabilitating flood-damaged parts contributes to a more sustainable automotive ecosystem by reducing waste and extending the life cycle of components.

- Learning Opportunity: For DIY enthusiasts, tackling the restoration of a flood-damaged part can be an invaluable learning experience, deepening their understanding of automotive mechanics and repair.

Navigating the Purchase: What to Inspect Before You Buy

Buying flood-damaged parts is not for the faint of heart or the unprepared. Thorough inspection is paramount. Here’s a systematic approach:

- Visual Inspection:

- Water Lines: Look for distinct "tide marks" on the part, indicating the maximum water level.

- Rust and Corrosion: Check for any signs of rust, especially in hidden crevices, bolt holes, and on electrical connectors. White, powdery corrosion on aluminum indicates water exposure.

- Silt and Mud Residue: Fine, gritty deposits in seams, joints, or around seals are a tell-tale sign.

- Mold/Mildew: For interior parts, look for fuzzy growths or discoloration.

- Cracks/Deformation: While less common directly from flood, strong currents or debris could cause physical damage.

- The Smell Test: A musty, moldy, or sewage-like odor is a strong indicator of prolonged water exposure and potential biological contamination, especially for interior components.

- Mechanical Check (for moving parts):

- Bearings/Joints: Check for excessive play, grinding, or stiffness. Try to rotate shafts or move joints.

- Fluid Contamination: If possible, check fluid levels and color. Milky or cloudy oil/fluid indicates water contamination.

- Smooth Operation: For parts like steering boxes or transfer cases, if you can turn input/output shafts, ensure smooth, resistance-free movement.

- Electrical Components:

- Connectors: Examine all electrical connectors for green, white, or black corrosion. This is a red flag.

- Wiring: Look for brittle or discolored wiring insulation.

- Functionality (if testable): While unlikely for loose parts, if buying an assembly, ask if it was tested before removal. Assume electrical parts are non-functional unless proven otherwise.

- Documentation and Seller Transparency:

- Source Vehicle History: If possible, ask about the donor vehicle’s salvage title or flood history. This isn’t always available for individual parts but can provide context.

- Seller Reputation: Buy from reputable salvage yards or sellers with good reviews who are transparent about the damage. Ask for detailed photos and videos, and don’t hesitate to ask specific questions. A good seller will be upfront about the part’s condition.

Types of Flood-Damaged Jeep Parts and Their Viability

Categorizing parts by their risk level helps in making informed decisions:

- High Risk (Often Not Recommended):

- Electronic Control Units (ECUs), Wiring Harnesses, Sensors: Extremely susceptible to water damage and corrosion. Repair is often impossible or unreliable.

- Interior Upholstery, Carpeting, Sound Deadening: Prone to mold, mildew, and persistent odors. Cleaning is often insufficient, and replacement is usually necessary.

- Infotainment Systems, Radios, Speakers: Highly complex electronics that are easily shorted or corroded.

- Airbags and Safety Restraint System (SRS) Components: Absolutely avoid. Safety critical and easily compromised by water.

- Medium Risk (Potentially Salvageable with Work):

- Engine Blocks and Cylinder Heads: If the engine was not hydro-locked (water sucked into cylinders causing catastrophic internal damage), and thoroughly flushed/inspected, they might be salvageable. Require complete disassembly, cleaning, and professional assessment.

- Transmissions, Transfer Cases, Differentials/Axles: These can suffer from water ingress and fluid contamination. They require complete disassembly, thorough cleaning, new bearings, seals, and gaskets. Labor-intensive but often viable for the mechanically inclined.

- Alternators, Starters, Power Steering Pumps: Can be rebuilt, but often more cost-effective to buy new or standard used.

- Low Risk (Often Good Candidates):

- Hard Tops and Soft Top Frames: If dried quickly, usually fine. Fabric on soft tops will likely need replacement due to mold/stains.

- Body Panels (Fenders, Doors, Hoods, Tailgates): Check for hidden rust in seams and under paint. If rust is surface-level, they can be cleaned, prepped, and repainted.

- Frames: Crucial to inspect for structural integrity and hidden rust inside boxed sections. If rust is superficial, they can be treated.

- Bumpers, Skid Plates, Rock Sliders: Often robust and only suffer from surface rust or cosmetic blemishes.

- Wheels: Inspect for cracks, bends, and balance issues. Corrosion on aluminum wheels can be cosmetic.

- Exterior Accessories (Light Bars, Winches – if sealed): Check for water ingress in sealed units. Winches might need motor and solenoid inspection/rebuild.

Restoration and Repair: Turning Damage into Value

The "discount" on a flood-damaged part often comes with the implicit understanding that it will require work.

- Cleaning Techniques:

- High-Pressure Washing: Effective for removing mud and silt from exterior and heavy mechanical parts.

- Wire Brushing/Sandblasting: For rust removal on metal components.

- Specialized Cleaners: For mold/mildew (bleach solutions, commercial mold removers) and degreasers for contaminated fluids.

- Ultrasonic Cleaners: Excellent for small, intricate metal parts.

- Rebuilding Components:

- Bearing and Seal Replacement: Essential for any mechanical part exposed to water.

- Gasket Replacement: Always replace for proper sealing.

- Electrical Connector Cleaning/Replacement: Use dielectric grease on new connections.

- Fluid Flushes: Multiple flushes for contaminated systems (e.g., power steering).

- Professional Assessment: For critical components like engine blocks, transmissions, or complex electrical systems, a professional mechanic or specialist can provide an accurate assessment and perform necessary machining or repairs.

- DIY vs. Professional: Weigh the cost of your time and required tools against the cost of professional repair. Sometimes, a "cheap" part becomes expensive when you factor in professional labor.

Challenges and Considerations

While appealing, the flood-damaged parts market presents several challenges:

- Hidden Damage: Corrosion can be insidious, spreading in unseen areas and manifesting months later.

- Electrical Nightmares: Even if a circuit dries and seems to work, residual corrosion can cause intermittent, hard-to-diagnose problems.

- Health Risks: Mold, bacteria, and chemical residues from contaminated floodwaters can pose health hazards during handling and cleaning. Wear appropriate PPE (gloves, masks).

- Resale Value Impact: Using flood-damaged components on your primary vehicle could potentially affect its future resale value, especially if not fully disclosed.

- Time and Effort: What seems like a bargain can quickly become a time sink, requiring significant effort for cleaning, inspection, and rebuilding.

- No Warranty/Return Policy: Most flood-damaged parts are sold "as-is," with no warranty or return options.

Practical Advice and Actionable Insights

- Buy Smart, Not Just Cheap: The lowest price isn’t always the best deal if the part is irreparable or requires extensive, costly work.

- Assume the Worst, Hope for the Best: Approach every flood-damaged part with skepticism. Assume it needs significant work or might be unusable until proven otherwise.

- Always Factor in Repair/Rebuild Costs: Add the estimated cost of cleaning, new seals, bearings, and potential professional labor to the initial purchase price to get a true cost.

- Focus on Mechanical and Structural Parts; Be Wary of Electronics and Interiors: This is the golden rule. Mechanical parts can often be restored; complex electronics rarely can be reliably.

- Source from Reputable Sellers: Prioritize transparency. A seller who provides detailed photos, openly discusses the damage, and answers questions is more trustworthy.

- Join Jeep Forums and Communities: Leverage the experience of others. Ask for advice on specific parts or common issues related to flood damage.

Flood Damaged Jeep Parts For Sale: Example Price Guide

Please note: This table provides estimated ranges and general guidance. Actual prices, conditions, and repair costs vary significantly based on the specific part, the extent of flood damage, the Jeep model and year, seller, and market demand. Always inspect parts thoroughly and factor in potential repair costs before purchase.

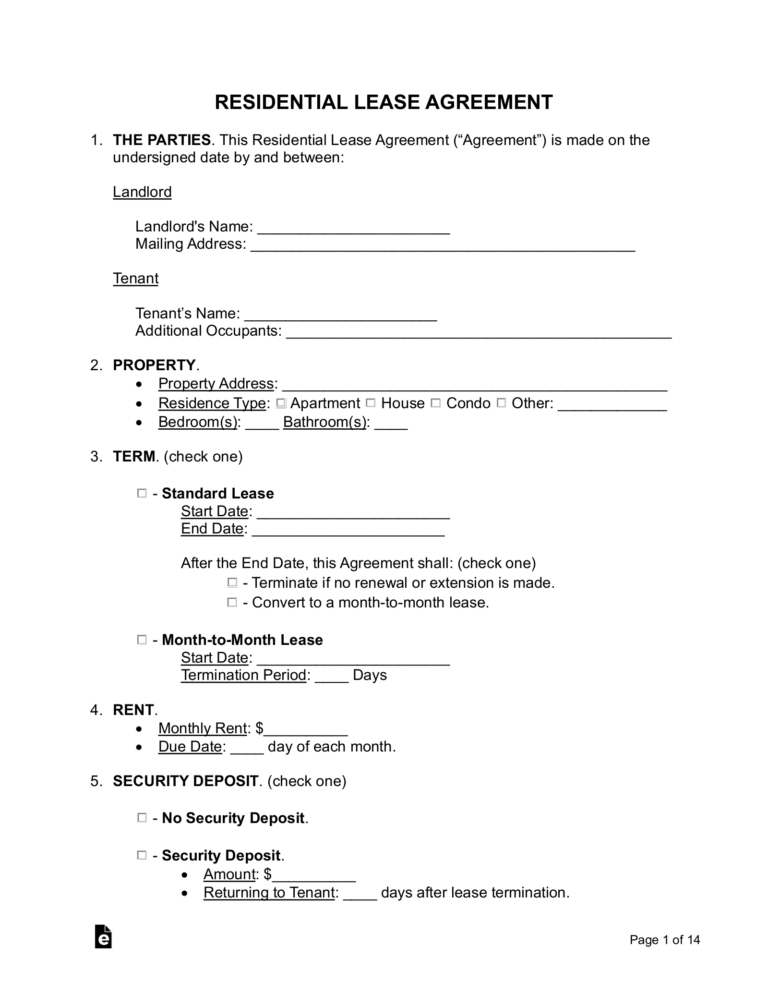

| Part Category | Example Parts (Jeep JK/JL) | Typical Condition (Flood Damaged) | Estimated Discount Range (vs. Used Non-Damaged) | Potential Repair/Rebuild Cost (Estimate) | Notes/Viability |

|---|---|---|---|---|---|

| Body/Exterior | Fenders, Doors, Hood, Hard Top, Bumpers, Wheels | Surface rust, cosmetic blemishes, water lines, minor dents | 50-80% | Low to Medium ($50-$500) | Often good candidates if structural integrity is sound. Paint & rust treatment. |

| Drivetrain (Heavy) | Axle Assemblies (Front/Rear), Transfer Case, Transmission | Water ingress, contaminated fluids, potential bearing/seal damage | 40-70% | Medium to High ($300-$1500+) | Require complete disassembly, cleaning, and new seals/bearings. High labor. |

| Engine Components | Engine Block, Cylinder Head, Oil Pan, Intake Manifold | Silt/water contamination, rust in cylinders (if hydro-locked) | 30-60% | High ($500-$2000+) | Risky. Only if confirmed not hydro-locked and full rebuild planned. |

| Suspension/Steering | Control Arms, Coils, Leaf Springs, Tie Rods, Steering Box | Surface rust, seized bushings/joints, contaminated fluid (steering box) | 40-70% | Low to Medium ($100-$600) | Good candidates if rust is superficial; steering box needs careful inspection. |

| Electrical/Interior | ECU, Wiring Harness, Seats, Carpet, Dash, Infotainment | Corrosion, short circuits, mold, mildew, non-functional | 70-95% | Very High (often non-repairable) | Extremely High Risk. Generally not recommended unless for parts only. |

| Accessories | Winch, Light Bar, Rock Sliders, Fender Flares | Water ingress, electrical issues (winch/lights), surface rust | 50-85% | Low to Medium ($50-$400) | Check sealing and functionality carefully. |

Frequently Asked Questions (FAQ)

Q1: Are flood-damaged parts safe to use?

A: It depends heavily on the specific part and the extent of the damage. Mechanical parts that can be thoroughly cleaned, inspected, and rebuilt (e.g., axles, certain engine components) can be made safe. However, safety-critical components like airbags, brake system parts, or complex electronics are generally not recommended due to unpredictable and often untraceable failures. Thorough inspection and professional assessment are crucial.

Q2: How can I tell if a part is flood damaged?

A: Look for tell-tale signs such as water lines or tide marks, excessive rust or corrosion in unusual places, silt or mud residue in crevices, musty or moldy odors (especially for interior parts), and green/white corrosion on electrical connectors.

Q3: What types of Jeep parts are generally okay to buy flood damaged?

A: Parts that are mostly mechanical or structural with minimal electronics and can be fully disassembled, cleaned, and rebuilt are often good candidates. Examples include body panels (if rust is superficial), frames (if structurally sound), hard tops, axle housings, and sometimes heavy-duty drivetrain components like transfer cases or differentials, provided you plan a complete rebuild.

Q4: What parts should I absolutely avoid buying flood damaged?

A: You should be extremely cautious or avoid altogether: any electronic control modules (ECU, BCM, TIPM), wiring harnesses, sensors, airbags and SRS components, seats, carpets, and other interior components prone to mold and persistent odors. Critical engine internals should also be avoided unless you are prepared for a full, professional rebuild.

Q5: Will using flood-damaged parts affect my Jeep’s resale value?

A: Potentially, yes. If you use flood-damaged parts, especially major components, it’s generally advisable to disclose this to potential buyers, as it could affect their perception of the vehicle’s long-term reliability and therefore its value.

Q6: Where can I find flood-damaged Jeep parts for sale?

A: You can often find them at large automotive salvage yards, online marketplaces (like eBay, Craigslist, or Facebook Marketplace), specialized auto parts recyclers, and sometimes directly from individuals after a major flood event. Look for listings that explicitly mention "flood damage" or salvage titles.

Q7: Is it worth buying flood-damaged parts for a daily driver?

A: Generally, it’s not recommended for a daily driver unless you are an experienced mechanic and can personally guarantee the part’s integrity after thorough inspection and rebuilding. The unpredictable nature of hidden damage, especially electrical, can lead to costly and inconvenient breakdowns. It’s more suited for project vehicles, off-road rigs, or those with very specific, limited needs where reliability tolerances are different.

Conclusion

The market for flood-damaged Jeep parts offers a unique opportunity for significant cost savings, particularly for those with mechanical aptitude, a project vehicle, or the need for hard-to-find components. However, it is a market that demands extreme caution, diligent inspection, and realistic expectations. The initial low price is often just the beginning, requiring an investment of time, effort, and potentially additional funds for cleaning, rebuilding, or professional assessment.

By understanding the types of damage, knowing what to look for, and recognizing the inherent risks, savvy buyers can navigate this niche effectively. Approach with knowledge, inspect thoroughly, and always factor in the true cost of bringing a flood-damaged part back to life. For the right individual and the right project, flood-damaged Jeep parts can indeed be a valuable resource, turning what seems like misfortune into a smart, cost-effective solution for your Jeep.