Is Jeep Wrangler Reliable? A Deep Dive into the Icon’s Durability

Is Jeep Wrangler Reliable? A Deep Dive into the Icon’s Durability jeeps.truckstrend.com

The Jeep Wrangler. Just the name conjures images of rugged trails, open-air freedom, and an undeniable spirit of adventure. Few vehicles boast such an iconic status and dedicated following. Yet, beneath the allure of its go-anywhere capability, a fundamental question often arises for potential owners and enthusiasts alike: "Is the Jeep Wrangler reliable?"

This isn’t a simple yes or no answer. The concept of reliability, especially for a vehicle designed for extreme conditions, is nuanced. For some, reliability means never breaking down, like a meticulously engineered commuter car. For Wrangler owners, it often means a vehicle that can get you there and, more importantly, back, even if it requires a bit more hands-on attention along the way. This article will thoroughly explore the multifaceted nature of Jeep Wrangler reliability, dissecting its common concerns, inherent strengths, and what owners can do to maximize its lifespan.

Is Jeep Wrangler Reliable? A Deep Dive into the Icon’s Durability

Defining Reliability in the Context of the Jeep Wrangler

Before diving into specifics, it’s crucial to establish what "reliability" signifies for the Jeep Wrangler. Unlike a typical sedan or SUV, the Wrangler is built for purpose: off-road prowess. This design philosophy influences its components, construction, and expected performance.

- Traditional Reliability Metrics: When consumer reports discuss reliability, they often refer to the frequency and severity of repairs needed during a vehicle’s early life, focusing on powertrain, electronics, and general component integrity. By these metrics, the Wrangler often scores average to below-average compared to its more road-focused counterparts.

- Off-Road Reliability: For the Wrangler, reliability also encompasses its ability to withstand extreme stresses – traversing uneven terrain, enduring mud, water, and rocks, and the inherent stresses of articulation and heavy use. Its robust body-on-frame construction, solid axles, and protective skid plates are designed precisely for this kind of "reliable" performance in challenging environments.

- Repairability and Parts Availability: A key aspect of long-term reliability for a vehicle like the Wrangler is its ease of repair and the vast aftermarket support. Issues might arise, but the ability to diagnose, find parts, and fix problems relatively easily (often by owners themselves) contributes significantly to its perceived long-term durability and usability.

Understanding this dual definition is key to assessing the Wrangler’s true reliability.

![]()

Common Reliability Concerns and Known Issues

Despite its rugged appeal, the Jeep Wrangler is not without its common quirks and potential issues. Being aware of these can help prospective buyers make informed decisions and current owners prepare for potential maintenance.

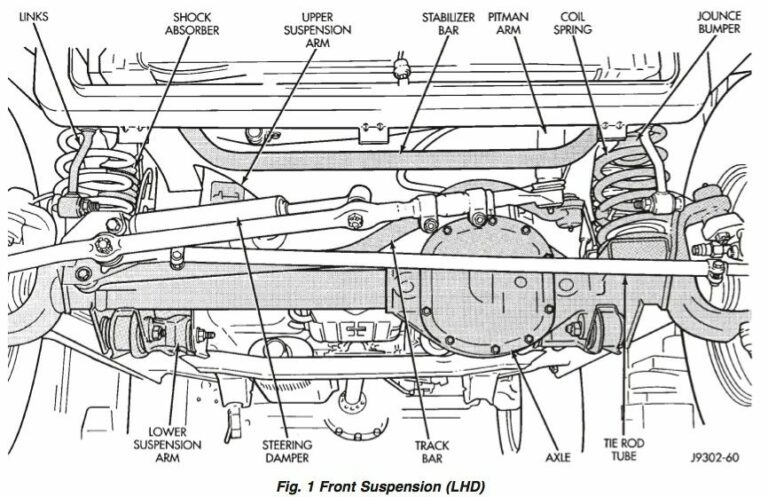

- Steering and Suspension Components: This is a frequently cited area of concern, particularly for JK (2007-2018) and early JL (2018-present) models. Issues can range from the infamous "death wobble" (a violent shaking of the steering wheel at speed, often due to loose or worn steering components like ball joints, tie rods, or track bar) to premature wear of bushings, shocks, and steering gears. Heavy off-roading and large aftermarket tires can accelerate this wear.

- Electrical Issues: Modern Wranglers, with their increasing reliance on electronics, can experience sensor failures, infotainment glitches, power window motor failures, and issues with the TIPM (Totally Integrated Power Module) in older models, which can cause various electrical woes.

- Fluid Leaks: Jeep engines and transmissions are known to develop leaks over time. Common culprits include oil pan gaskets, oil cooler housing leaks (especially on 3.6L Pentastar engines), and transfer case or differential seals.

- Rust: While newer models have improved rust protection, older TJs and JKs, especially in areas with road salt, are susceptible to frame rust, body panel corrosion, and exhaust system deterioration. Regular undercarriage cleaning is crucial.

- HVAC System: Issues with the air conditioning compressor, blend door actuators, or blower motor are not uncommon.

- Soft Top and Hard Top Leaks: Water leaks from the roof or doors are a recurring complaint, often due to worn seals, misaligned panels, or clogged drain channels. While not mechanically critical, they can be frustrating.

- Specific Powertrain Concerns (Model Dependent):

- 3.8L V6 (JK 2007-2011): Known for oil consumption and potential cylinder head issues.

- 3.6L Pentastar V6 (JK 2012-2018, JL 2018-Present): Generally more reliable, but can have oil cooler housing leaks, rocker arm/lifter issues (ticking noise), and occasional cam phaser problems.

- ZF 8-speed automatic (JL): Generally robust, but early models had software quirks.

- Manual Transmissions: Clutch wear and shifter linkage issues are possible, especially with aggressive off-roading.

Factors Influencing Wrangler Reliability

Several factors play a significant role in how reliable your specific Jeep Wrangler will be:

- Maintenance Regimen: This is paramount. Adhering to the manufacturer’s recommended service intervals for oil changes, fluid flushes, filter replacements, and regular inspections can significantly extend the life of components and prevent minor issues from becoming major ones.

- Driving Habits and Usage: A Wrangler primarily used for daily commuting on paved roads will generally experience fewer mechanical stresses than one regularly pushed to its limits off-road. Aggressive driving, heavy towing, or frequent, demanding off-road excursions will naturally accelerate wear and tear.

- Aftermarket Modifications: The Jeep Wrangler is one of the most modified vehicles on the planet. Lift kits, larger tires, heavy bumpers, and performance upgrades can drastically alter the vehicle’s dynamics and put additional stress on factory components (e.g., axles, steering, drivetrain). Poorly installed or incompatible modifications are a leading cause of reliability issues.

- Model Year and Generation: Reliability trends can vary between generations (YJ, TJ, JK, JL). Researching specific model years can reveal common issues or improvements. Generally, later model years within a generation often benefit from resolved issues from earlier production runs.

- Engine and Transmission Combinations: While all Wrangler powertrains are designed for rugged use, some combinations have proven more robust or have fewer known widespread issues than others. The 3.6L Pentastar engine paired with the 8-speed automatic transmission in the JL generation is generally considered a solid combination.

Strengths and What Makes the Wrangler "Reliable" in its Own Way

Despite its common quirks, the Jeep Wrangler possesses several inherent strengths that contribute to its unique form of reliability and longevity:

- Robust Body-on-Frame Construction: This traditional design provides a strong, durable platform that can withstand significant abuse, especially off-road. It’s designed to flex and absorb impacts, protecting the cabin and occupants.

- Solid Axles: While they can contribute to "death wobble" if not properly maintained, solid axles are incredibly strong and durable for off-road use, offering excellent articulation and ground clearance.

- Simplicity (Especially Older Models): Earlier Wrangler generations (TJ, YJ) were relatively simple mechanically, making them easier to diagnose and repair. This simplicity often translates to fewer complex systems that can fail.

- Vast Aftermarket Support and Parts Availability: This is a massive advantage. Nearly every component of a Wrangler can be replaced or upgraded with aftermarket parts, often stronger than OEM. This abundance of parts, combined with a passionate community, means repairs are rarely impossible or prohibitively expensive due to parts scarcity.

- Ease of Repair: Many common Wrangler issues, particularly those related to steering and suspension, are relatively straightforward for a competent mechanic or even a DIY enthusiast to address, thanks to the vehicle’s accessible design and the wealth of online resources.

- Strong Resale Value: The Wrangler consistently holds its value exceptionally well. While not a direct measure of reliability, it indicates a perceived long-term value and desirability in the market, suggesting that buyers aren’t afraid of its long-term prospects.

Practical Advice and Actionable Insights for Maximizing Your Wrangler’s Reliability

If you own a Wrangler or are considering buying one, here’s how you can proactively enhance its reliability and minimize potential headaches:

- Follow the Maintenance Schedule Diligently: This is the most critical step. Don’t skip oil changes, fluid checks, or recommended service intervals. Pay particular attention to differential fluid, transfer case fluid, and transmission fluid changes, especially if you off-road.

- Conduct Regular Inspections: Periodically inspect steering components (tie rods, drag link, track bar, ball joints), suspension bushings, and fluid levels. Listen for unusual noises and address them promptly.

- Choose Modifications Wisely: If you plan to modify your Wrangler, research thoroughly. Invest in quality parts from reputable manufacturers. Understand how a lift kit or larger tires might impact other components and upgrade those components (e.g., steering, brakes, axles) as needed to maintain balance and reliability. Professional installation is highly recommended for complex modifications.

- Address Issues Promptly: Don’t ignore warning lights or strange noises. Small issues can quickly escalate into expensive repairs if left unaddressed.

- Learn Basic DIY Maintenance: The Wrangler community is incredibly supportive. Learning to perform basic tasks like fluid checks, filter changes, and even some steering component replacements can save money and give you a better understanding of your vehicle.

- Wash the Undercarriage Regularly: Especially if you live in an area with road salt or frequently go off-roading in mud or sand, regularly washing the underside of your Wrangler can prevent rust and corrosion.

Estimated Annual Maintenance & Repair Costs for Jeep Wrangler

Understanding the potential costs associated with ownership is part of assessing overall reliability. The table below provides estimated average annual maintenance and repair costs for a Jeep Wrangler. These figures can vary significantly based on model year, mileage, driving habits, geographical location, and whether repairs are done by a dealership, independent mechanic, or DIY.

| Category | Common Issues/Components | Estimated Average Repair Cost Range (Per Incident) | Annual Average (Estimate) | Notes |

|---|---|---|---|---|

| General Maintenance | Oil Changes, Tire Rotations, Fluid Checks, Filter Replacements | $100 – $300 | $300 – $600 | Includes routine services; varies with synthetic oil. |

| Steering & Suspension | Ball Joints, Tie Rods, Track Bar, Shocks, Bushings, "Death Wobble" components | $300 – $1,500+ | $200 – $500 | Highly variable based on component failure and if multiple parts are replaced. |

| Brakes | Brake Pads, Rotors, Calipers, Brake Lines | $200 – $800 | $150 – $350 | Front and rear brakes can be done at different times. |

| Electrical | Sensors (O2, ABS, Crankshaft), Window Motors, TIPM, Wiring | $150 – $1,000+ | $100 – $300 | Diagnostic time can add to cost. Some issues require specialist tools. |

| Powertrain (Engine/Trans) | Fluid Leaks (Oil Cooler, Gaskets), Spark Plugs, Belt Replacement, Minor Transmission Service | $200 – $1,500+ | $250 – $700 | Major engine/transmission issues can be several thousands. |

| HVAC | A/C Compressor, Blower Motor, Blend Door Actuator | $300 – $1,200 | $50 – $200 | Less frequent, but can be costly when they occur. |

| Miscellaneous | Wiper Motor, Door Seals, Minor Rust Treatment, Top Leaks | $100 – $500 | $50 – $150 | Often DIY-friendly. |

| Overall Annual Average | N/A | $500 – $1,500 | This is a broad estimate. It can be lower for well-maintained vehicles, higher for neglected ones. |

Note: These figures are estimates and can vary widely. Major component failures (e.g., engine replacement, transmission rebuild) can easily cost several thousand dollars and are not factored into the "annual average" but are possibilities over the vehicle’s lifespan.

Concluding Summary: A Reliable Icon, With Caveats

So, "Is the Jeep Wrangler reliable?" The answer is complex, but generally, yes, within its unique context. It’s not the kind of "reliable" that means you’ll never visit a mechanic. Instead, it offers a distinct form of durability: it’s built tough for its intended purpose, often capable of pushing through challenges that would sideline other vehicles, and remarkably repairable when issues do arise.

The Wrangler demands a proactive owner – one who understands its design purpose, commits to regular maintenance, and is prepared to address its known quirks. For those who embrace this relationship, the Wrangler offers an unparalleled driving experience, a vibrant community, and a vehicle that, despite its occasional demands, proves its worth time and again on the open road and rugged trail. It’s a reliable companion for adventure, provided you understand and respect its unique character.

Frequently Asked Questions (FAQ)

Q1: Which Jeep Wrangler generation is the most reliable?

A1: There’s no single "most reliable" generation, as each has its strengths and common issues. However, the 3.6L Pentastar engine found in later JK models (2012-2018) and all JL models (2018-present) is generally considered a more robust and reliable engine than the older 3.8L V6. The JL generation has also seen improvements in overall build quality and features, though early models had some teething issues.

Q2: Are older Jeep Wranglers more reliable than newer ones?

A2: Older Wranglers (TJ, YJ) benefit from simpler mechanical designs, which can make them easier and cheaper to repair. They have fewer complex electronic systems that can fail. However, they are also more susceptible to rust and age-related wear and tear. Newer Wranglers (JK, JL) offer more modern features, comfort, and often more refined powertrains, but come with increased complexity that can lead to different types of issues.

Q3: Is the Jeep Wrangler expensive to maintain?

A3: Compared to some standard commuter vehicles, the Jeep Wrangler can be more expensive to maintain, especially if you factor in potential repairs for common issues like steering components or fluid leaks. Off-roading significantly increases wear and tear, leading to higher maintenance and repair costs. However, parts are widely available, and many repairs can be done by independent mechanics or even DIY, which can help manage costs.

Q4: Does off-roading ruin a Wrangler’s reliability?

A4: Off-roading inherently puts more stress on a vehicle’s components, leading to accelerated wear and tear. While Wranglers are built for it, frequent or extreme off-roading will necessitate more rigorous maintenance, more frequent inspections, and potentially more repairs. It doesn’t "ruin" reliability, but it demands more attention and investment to maintain it.

Q5: What is the "death wobble" and how can it be fixed?

A5: The "death wobble" is a violent, uncontrollable shaking of the front end of a solid-axle vehicle, including the Jeep Wrangler, typically occurring at highway speeds after hitting a bump. It’s usually caused by worn or loose components in the steering and suspension system, such as the track bar, ball joints, tie rod ends, or steering damper. Fixing it involves identifying and replacing the worn components, often with stronger aftermarket parts, and ensuring proper alignment. It’s a critical safety issue that should be addressed immediately.

Q6: How long do Jeep Wranglers typically last?

A6: With proper maintenance and care, a Jeep Wrangler can last for 150,000 to 200,000 miles or even more. Many owners report getting well over 200,000 miles from their Wranglers. Longevity largely depends on how the vehicle is used, how well it’s maintained, and if issues are addressed promptly.