Jeep F 134 Engine For Sale: A Comprehensive Buyer’s Guide to the Legendary Hurricane

Jeep F 134 Engine For Sale: A Comprehensive Buyer’s Guide to the Legendary Hurricane /jeeps.truckstrend.com

The iconic silhouette of a vintage Willys or early CJ Jeep evokes images of rugged durability, adventurous spirit, and unwavering reliability. At the heart of many of these beloved machines, particularly from the 1950s and 60s, beats the legendary Jeep F-134 Hurricane engine. More than just a collection of metal and moving parts, the F-134 is a testament to an era of straightforward, robust engineering designed to conquer any terrain. For enthusiasts, restorers, and those seeking to breathe new life into a classic Jeep, finding a Jeep F-134 engine for sale isn’t merely a transaction; it’s an investment in automotive history and a gateway to countless future adventures.

This comprehensive guide is designed to serve as your ultimate resource in navigating the world of F-134 engine acquisition. We’ll delve into what makes this engine special, where to find it, what to look for, and how to make an informed purchase, ensuring your restoration or replacement project gets the dependable heart it deserves.

Jeep F 134 Engine For Sale: A Comprehensive Buyer’s Guide to the Legendary Hurricane

Understanding the F-134 Engine: A Legacy of Durability

The F-134 Hurricane engine is an overhead-valve (OHV) inline-four gasoline engine, famously succeeding the L-134 "Go-Devil" flathead engine. Introduced in 1950, the F-134 quickly became the workhorse for a variety of Willys and Kaiser-Jeep vehicles. Its "F-head" designation comes from its unique valve arrangement, where the intake valves are in the cylinder head (overhead) and the exhaust valves are in the block (flathead style). This design offered a significant power increase over its predecessor while retaining much of the simplicity and legendary durability Willys was known for.

Key Specifications and Applications:

- Displacement: 134 cubic inches (2.2 liters)

- Horsepower: Typically 70-75 hp at 4000 rpm (varied slightly by application)

- Torque: Approximately 114 lb-ft at 2000 rpm

- Valvetrain: F-head (OHV intake, side-valve exhaust)

- Common Applications:

- Willys CJ-3B (1953-1968)

- Willys/Kaiser Jeep CJ-5 (1955-1971)

- Willys/Kaiser Jeep CJ-6 (1955-1971)

- M38A1 military Jeeps (1952-1971)

- Willys FC-150 and FC-170 Forward Control trucks

- Jeep DJ-3A (Dispatch Jeeps)

The F-134’s enduring appeal lies in its straightforward design, making it relatively easy to maintain and repair. Its robust construction means many engines from the 1950s are still in service today, a testament to their inherent quality. For anyone embarking on a vintage Jeep project, sourcing a reliable F-134 is often a top priority.

Why Buy a Used Jeep F-134 Engine? Common Scenarios

The decision to seek out a Jeep F-134 engine for sale typically stems from a few core needs:

- Restoration Projects: The most common reason. To maintain historical accuracy and originality, purists insist on the correct F-134 engine for their CJ-3B, CJ-5, or M38A1 restorations. A numbers-matching engine, or at least a period-correct one, significantly enhances a vehicle’s value and authenticity.

- Engine Replacement: Sometimes, the original engine in a beloved Jeep has suffered catastrophic failure (e.g., cracked block, severe internal damage) that makes repair impractical or impossible. A replacement F-134 offers a direct, reliable swap without the complexities of engine conversions.

- Parts Donor: Even if you don’t need a complete engine, acquiring one for parts can be cost-effective. Specific components like the carburetor, distributor, manifolds, or even internal parts can be salvaged to repair your existing F-134.

- Custom Builds/Period Correct Swaps: While less common, some customizers might use an F-134 for a period-correct hot rod or custom build where a simple, reliable vintage engine is desired.

Where to Find a Jeep F-134 Engine For Sale

The search for an F-134 can be an adventure in itself. Here are the most common avenues:

- Online Marketplaces:

- eBay: Often has a selection of F-134s in various conditions, from core engines to freshly rebuilt units. Be diligent with seller feedback and ask for detailed photos/videos.

- Craigslist/Facebook Marketplace: Excellent for local finds, potentially saving on shipping costs. Exercise caution and arrange to inspect in person.

- Dedicated Classic Car/Jeep Forums & Facebook Groups: Communities like "Willys Jeep Parts" or "Vintage Jeep Owners" are invaluable. Members often sell parts directly, and you benefit from collective knowledge and trusted sellers.

- Specialized Vintage Jeep Parts Dealers/Restoration Shops: These businesses often stock or can source F-134 engines, particularly rebuilt ones. While potentially more expensive, they typically offer quality assurance and sometimes a warranty. Examples include Omix-ADA (though they primarily sell parts, not full engines), or smaller, dedicated Jeep restoration outfits.

- Salvage Yards/Junkyards: Less likely to find a running engine, but you might discover a complete engine as a core or for specific components. It requires patience and a good eye.

- Auctions: Classic car auctions or even industrial auctions can occasionally feature vintage Jeeps or loose engines.

- Word-of-Mouth: Networking with local Jeep clubs, mechanics specializing in vintage vehicles, or attending classic car shows can lead to unexpected finds.

Practical Advice: When using online platforms, always prioritize sellers who provide clear, high-resolution photos from multiple angles, detailed descriptions, and are willing to answer questions thoroughly. Avoid vague listings or sellers who push for quick decisions.

What to Look For: Essential Inspection Tips for a Used F-134

Acquiring a used engine requires careful inspection to avoid costly surprises. Whether you’re buying a running engine or a core for rebuilding, here’s what to check:

- Visual Inspection:

- Cracks: Look closely at the block and cylinder head for any signs of cracks, especially around freeze plugs, manifold mounting surfaces, or mounting points. These can be deal-breakers.

- Rust: Surface rust is common and generally fine. Heavy, deep rust, especially around sealing surfaces or within the cylinders, indicates neglect and potential issues.

- Previous Repairs: Look for evidence of welding, brazing, or excessive sealant, which could indicate attempts to hide damage.

- Completeness: Is the engine a "long block" (block, head, rotating assembly) or a "dressed" engine with accessories like the carburetor, distributor, fuel pump, manifolds, flywheel, and bellhousing? Missing components will add to your cost.

- Oil & Coolant: Check the oil for sludge, milky consistency (water contamination), or metallic flakes. Look at the coolant passages (if accessible) for rust or oil residue.

- Internal Inspection (if possible):

- Compression Test: If the engine is runnable, a compression test is paramount. Low or uneven compression indicates worn rings, valves, or head gasket issues.

- Oil Pan: If buying a core, removing the oil pan can reveal sludge, debris, or excessive metal in the bottom, signaling severe internal wear.

- Cylinder Walls: If the head is off, inspect the cylinder walls for scoring, rust pitting, or a significant ridge at the top, which indicates wear.

- Crankshaft Play: Check for excessive end play or up-and-down movement in the crankshaft, which can indicate worn thrust bearings or main bearings.

- Running Condition (if applicable):

- Listen: Any knocking, tapping, or loud ticking sounds are red flags.

- Smoke: Blue smoke indicates oil burning, white smoke could be coolant, and black smoke suggests rich fuel mixture.

- Leaks: Look for active oil, coolant, or fuel leaks.

- Oil Pressure: Check if it holds adequate oil pressure once warmed up.

- Paperwork/History: Ask if the seller has any documentation, such as service records, previous rebuild receipts, or information on the engine’s original vehicle.

Actionable Insight: If buying remotely, insist on a video of the engine running (if applicable) and multiple high-resolution photos of specific areas you request. For local purchases, always bring a knowledgeable friend or mechanic if you’re not confident in your own inspection skills.

Pricing Your Purchase: Factors Influencing F-134 Engine Cost

The price of a Jeep F-134 engine for sale can vary widely based on several factors:

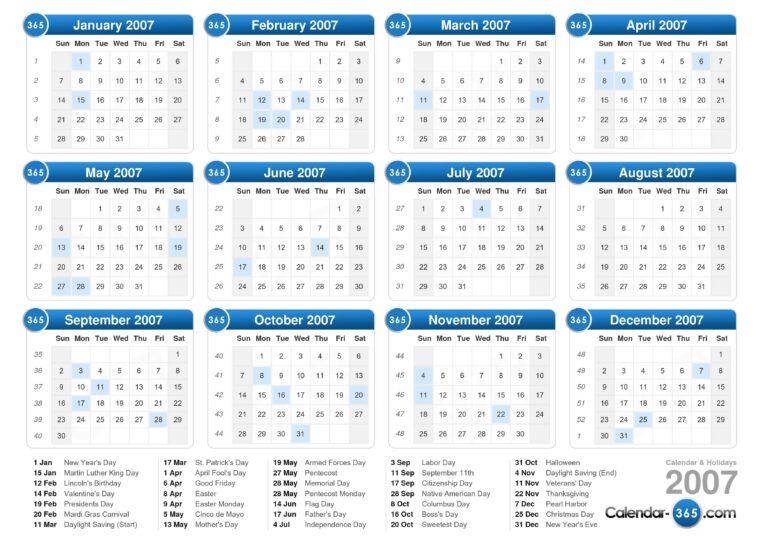

| Condition Category | Description | Estimated Price Range (USD) | Notes |

|---|---|---|---|

| Core/Parts Engine | Not running, seized, or significantly damaged; suitable only for parts or a complete rebuild. | $300 – $800 | May be missing components. High risk, significant investment needed for rebuild. Good for specific parts. |

| Rebuildable Core | Turns over freely, no major cracks, but needs full overhaul (machining, new internals). | $800 – $1,500 | Best option for a DIY rebuild or sending to a machine shop. Ensure block and head are crack-free. |

| Running Used Engine | Currently runs, but condition is unknown (e.g., smokes, low compression, leaks). | $1,500 – $2,500 | High risk; often needs a rebuild shortly after purchase. Only consider if you can thoroughly inspect or hear it run. |

| Professionally Rebuilt | Fully disassembled, machined, new bearings, rings, pistons, valves, seals, and tested by a professional. | $3,500 – $6,000+ | Often comes with a warranty. Best for peace of mind, but highest upfront cost. Verify what "rebuilt" entails (long block vs. complete dressed). Shipping costs can be substantial. |

Additional Factors Affecting Price:

- Completeness: A "dressed" engine with carburetor, distributor, starter, and generator will command a higher price than a bare long block.

- Seller Reputation: Reputable sellers or specialized shops often charge more but offer greater reliability and support.

- Location & Shipping: Large, heavy items like engines incur significant freight costs, which can add hundreds of dollars to the final price.

- Rarity/Specific Variants: An F-134 from a rare M38A1 military Jeep might fetch a premium due to specific features or originality.

Practical Advice: Always factor in potential rebuilding costs, shipping, and any missing components when evaluating a price. A seemingly cheap engine can quickly become expensive if it requires extensive work.

Rebuilding vs. Buying a Rebuilt F-134 Engine

This is a critical decision for many buyers:

Buying a Professionally Rebuilt Engine:

- Pros:

- Peace of Mind: Often comes with a warranty, guaranteeing the work.

- Time-Saving: Ready to install (or nearly so), minimizing downtime for your project.

- Quality: Rebuilders specialize in these engines and have the right tools and expertise.

- Cons:

- Higher Upfront Cost: Significantly more expensive than a used core.

- Less Control: You rely on the rebuilder’s definition of "rebuilt" (ask for details on what was replaced/machined).

- Shipping: Can be costly if the rebuilder is far away.

Rebuilding Your Own Core (or buying a rebuildable core):

- Pros:

- Cost Savings (Potentially): If you do the labor, you save on shop fees.

- Learning Experience: Invaluable for understanding your engine inside and out.

- Full Control: You choose the parts and ensure the quality of every step.

- Satisfaction: Immense pride in running an engine you rebuilt yourself.

- Cons:

- Time-Consuming: Can take weeks or months, especially for a first-timer.

- Tools & Knowledge: Requires specialized tools (e.g., engine stand, torque wrenches) and a good understanding of engine mechanics.

- Hidden Costs: Machining work (crank grinding, cylinder boring, valve jobs) adds up. Unexpected damaged parts can increase expenses.

- Risk of Errors: Mistakes can lead to costly failures.

Actionable Insight: Assess your mechanical skills, available time, and budget. If you’re new to engine work, consider buying a professionally rebuilt unit or finding a local, reputable machine shop to assist with your core. Many parts for the F-134 are readily available, including pistons, rings, bearings, gaskets, and valve components.

Installation and Post-Purchase Considerations

Once you’ve secured your F-134 engine, proper installation and initial care are crucial for its longevity:

- Pre-Installation Checks: Even if rebuilt, inspect all accessible seals and gaskets. Consider replacing the rear main seal (a common leak point) before installation. Clean all mating surfaces thoroughly.

- Proper Fluid Fills: Use the correct weight and type of engine oil (often a non-detergent or zinc-rich oil for flat tappet engines, or a modern oil specifically designed for older engines) and coolant.

- Initial Start-Up: For rebuilt engines, follow the rebuilder’s specific break-in procedure. This usually involves a period of varying RPMs to properly seat the camshaft and lifters.

- Monitoring: After starting, closely monitor oil pressure, coolant temperature, and listen for any unusual noises. Check for leaks.

- Ongoing Maintenance: The F-134 thrives on regular oil changes, proper cooling system maintenance, and periodic tune-ups (points, plugs, timing). Its simplicity makes it forgiving, but consistent care is key.

Conclusion

The Jeep F-134 Hurricane engine is more than just a historical artifact; it’s a living legend that continues to power thousands of classic Jeeps around the world. Finding a reliable F-134 for sale is a critical step in preserving these iconic vehicles. By understanding the engine’s unique characteristics, knowing where to search, diligently inspecting potential purchases, and considering the nuances of rebuilding versus buying rebuilt, you can confidently acquire the heart your vintage Jeep deserves.

The satisfaction of hearing that distinctive F-134 roar to life, knowing you’ve contributed to the enduring legacy of a true American workhorse, is a reward that far outweighs the effort of the search. Embark on your journey, armed with knowledge, and keep the spirit of the Jeep alive for generations to come.

Frequently Asked Questions (FAQ)

Q1: Is the F-134 engine a "flathead" engine?

A1: No, the F-134 Hurricane is an "F-head" or "IOE" (intake over exhaust) engine. Its predecessor, the L-134 Go-Devil, was the flathead engine. The F-134 has overhead intake valves and side-valve exhaust valves, distinguishing it from a true flathead where all valves are in the block.

Q2: What Jeep models typically used the F-134 Hurricane engine?

A2: The F-134 was widely used in Willys and Kaiser-Jeep vehicles from the early 1950s into the 1970s. Key models include the CJ-3B, CJ-5, CJ-6, M38A1 military Jeeps, FC-150/FC-170 Forward Control trucks, and the DJ-3A Dispatcher.

Q3: Are parts still available for the F-134 engine?

A3: Yes, generally, parts availability for the F-134 is quite good. Many specialized vintage Jeep parts suppliers and even some general automotive parts stores carry components like gaskets, seals, pistons, rings, bearings, and valve train parts.

Q4: What’s the typical lifespan of an F-134 engine?

A4: With proper maintenance and regular oil changes, an F-134 engine can last for many decades and hundreds of thousands of miles. Their simple, robust design contributes to their incredible longevity. Many original engines from the 1950s are still in operation today.

Q5: Can I upgrade the performance of an F-134 engine?

A5: While some minor performance enhancements are possible (e.g., carburetor upgrades, electronic ignition conversion), the F-134 is primarily known for its reliability and torque, not high horsepower. Significant performance upgrades are generally not practical or cost-effective for this engine. Most focus is on ensuring its dependable operation.

Q6: What’s the main difference between the F-134 and the L-134 engine?

A6: The primary difference is the valve train design. The L-134 ("Go-Devil") is a flathead engine with all valves in the block. The F-134 ("Hurricane") is an F-head engine with overhead intake valves and side-valve exhaust valves. This design allowed the F-134 to produce more horsepower and torque from the same displacement.