Jeep Front Control For Sale: Your Definitive Guide to Upgrading Your Ride

Jeep Front Control For Sale: Your Definitive Guide to Upgrading Your Ride jeeps.truckstrend.com

The iconic Jeep, a symbol of adventure and capability, is often pushed to its limits, both on and off the pavement. Whether you’re tackling challenging trails, enhancing its street manners, or simply replacing worn-out components, the integrity of your Jeep’s front end is paramount. This brings us to a crucial topic for any Jeep owner: Jeep Front Control For Sale.

But what exactly does "Jeep Front Control" encompass? While the term can broadly refer to various components that manage the front axle’s position and steering, it most commonly points to control arms – the unsung heroes of your Jeep’s suspension system. These vital links connect your front axle to the frame, dictating its fore-aft movement, setting critical caster angles, and influencing everything from ride quality and handling to articulation and stability. Beyond control arms, other key "front control" elements include track bars, tie rods, drag links, and ball joints, all working in concert to ensure your Jeep drives predictably and safely.

Jeep Front Control For Sale: Your Definitive Guide to Upgrading Your Ride

This comprehensive guide will delve into the world of Jeep front control components available for sale, offering insights into why they’re essential, what types are out there, how to choose the right ones, and what benefits they offer.

Understanding "Jeep Front Control": More Than Just Arms

At its core, the concept of "Jeep Front Control" revolves around maintaining precise control over your front axle. This is critical for steering responsiveness, managing suspension travel, and ensuring the tires maintain optimal contact with the road or trail.

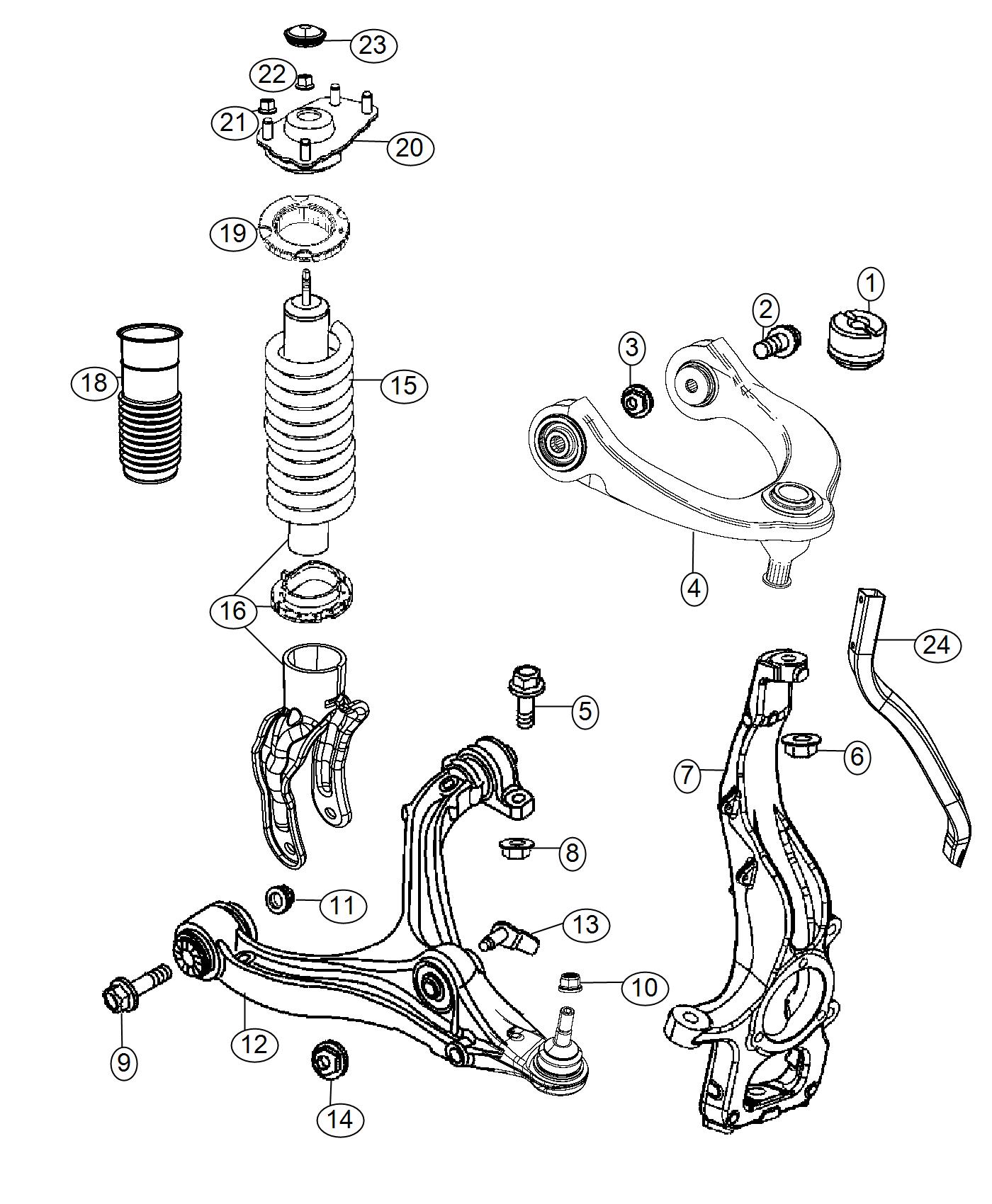

Control Arms (Upper and Lower): These are the primary focus when discussing "front control."

- Function: They locate the axle relative to the chassis. Lower control arms prevent the axle from moving backward under acceleration and forward under braking, while upper control arms primarily control the caster angle – a crucial alignment specification that affects steering stability and return-to-center feel.

- Importance: Worn or inadequate control arms can lead to poor handling, excessive tire wear, and even the dreaded "death wobble." When lifting a Jeep, stock control arms become too short, pulling the axle inward and negatively impacting caster, necessitating longer or adjustable replacements.

Other Key "Front Control" Components:

While control arms are central, other parts are often upgraded concurrently as part of a holistic front-end control solution:

- Track Bar: Locates the axle laterally (side-to-side) under the vehicle. An adjustable track bar is essential after a lift to re-center the axle.

- Tie Rod and Drag Link: These are steering components. A heavy-duty tie rod connects the steering knuckles, and the drag link connects the steering box to the tie rod. Upgrading these provides stronger, more precise steering.

- Ball Joints: Found in the steering knuckles, they allow the wheels to turn and pivot. Heavy-duty ball joints are crucial for lifted Jeeps running larger tires.

![]()

Together, these components ensure your Jeep’s front end is properly aligned, stable, and capable of handling the demands you place on it.

Why Seek "Jeep Front Control For Sale"? Common Motivations

The reasons for exploring the market for Jeep front control components are varied, but generally fall into these categories:

- Wear and Tear Replacement: Like any moving part, stock control arms and bushings wear out over time, especially with regular use or off-road excursions. Signs of wear include clunking noises, sloppy steering, uneven tire wear, and a generally loose feeling in the front end. Replacing these with quality aftermarket parts restores performance and safety.

- Lifting Your Jeep: This is arguably the most common reason. When you lift a Jeep, the distance between the frame and the axle increases. Stock control arms become too short, pulling the axle closer to the frame, altering the caster angle, and causing the axle to shift forward or backward. This leads to poor handling, steering issues, and reduced suspension articulation. Longer, adjustable control arms are critical to correct geometry and restore proper handling after a lift.

- Performance Upgrade & Durability: Stock components are designed for a balance of cost, comfort, and moderate off-road use. For those who frequently tackle challenging trails, heavier-duty control arms made from stronger materials (like chromoly steel) with superior joints offer increased durability, improved articulation, and greater resistance to bending or breaking.

- Addressing Handling Issues: If your Jeep suffers from "death wobble" (a violent, uncontrollable shaking of the front end), poor steering return-to-center, or general instability, worn or improper front control components are often the culprits. Upgrading to robust, adjustable parts is a key step in diagnosing and resolving these issues.

Types of Jeep Front Control Components: A Deeper Dive (Focus on Control Arms)

When browsing "Jeep Front Control For Sale," you’ll encounter a variety of options, primarily differing in adjustability, material, and joint type.

Control Arms:

-

Fixed Length Control Arms:

- Description: These are direct replacements for stock arms and come in a predetermined length. Some are slightly longer than stock to accommodate mild lifts (typically up to 2.5 inches).

- Pros: Generally less expensive, simpler to install (no adjustment needed).

- Cons: Limited in application; not suitable for higher lifts where precise caster adjustment is critical.

- Best For: Stock replacement, or very mild lifts where minor caster changes are acceptable.

-

Adjustable Control Arms:

- Description: Feature threaded ends that allow you to lengthen or shorten the arm. This is crucial for dialing in caster after a lift. They come in "short" (for 2-4.5 inch lifts) and "long" (for 4.5+ inch lifts) versions.

- Pros: Allows for precise axle positioning and caster adjustment, accommodates a wider range of lift heights, essential for optimal handling and alignment.

- Cons: More expensive, requires proper setup and alignment after installation.

- Best For: Any lifted Jeep, especially 2.5 inches and above, and for those seeking optimal performance.

-

Material:

- Steel: Most common, durable, cost-effective. High-strength steel is standard for aftermarket arms.

- Chromoly Steel: A higher-grade steel alloy that offers superior strength-to-weight ratio. Lighter and stronger than standard steel, ideal for hardcore off-roading and competition. More expensive.

-

Joint Types (Where the Arm Connects to Frame/Axle):

- Rubber Bushings: Similar to stock, provide a compliant ride, absorb vibrations, good for daily driving. Limited articulation.

- Polyurethane Bushings: Firmer than rubber, offer better road feel and articulation than stock, more durable, but can transmit more road noise (NVH) and may require greasing.

- Heim Joints (Spherical Rod Ends): Offer maximum articulation, very strong, but can be noisy, require regular maintenance (greasing), and are not sealed, making them susceptible to dirt/water intrusion. Best for dedicated off-road vehicles.

- Flex Joints (e.g., Currie Johnny Joints, TeraFlex FlexArms): Proprietary designs that combine the articulation of a Heim joint with the durability and noise reduction of a bushing. Often sealed and rebuildable, making them an excellent choice for a balance of on-road comfort and off-road performance.

Other "Front Control" Components:

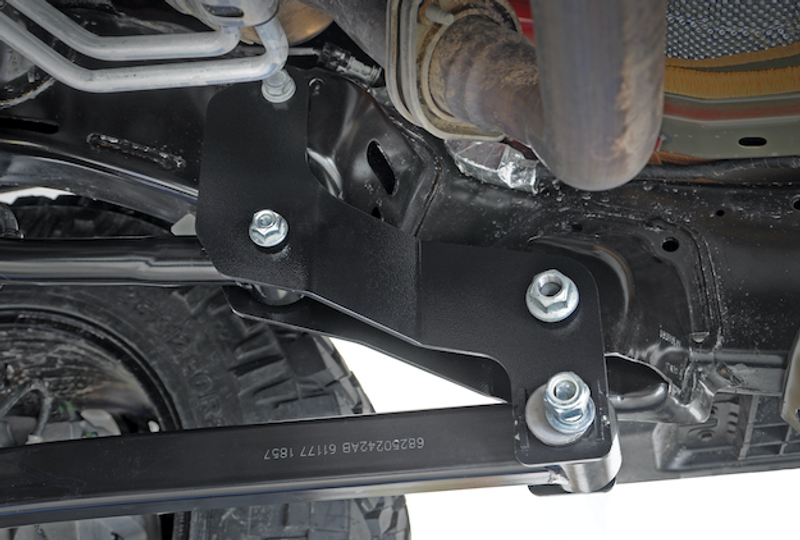

- Adjustable Track Bars: Essential for re-centering the front axle after a lift.

- Heavy-Duty Tie Rods and Drag Links: Thicker, stronger components that resist bending and provide more precise steering for larger tires.

- Heavy-Duty Ball Joints: Replace stock ball joints, designed to withstand the increased stress from larger tires and aggressive off-roading.

Benefits of Upgrading Your Jeep’s Front Control

Investing in quality front control components offers a multitude of advantages:

- Improved Ride Quality & Handling: Properly set caster and axle position lead to a more stable, predictable, and comfortable ride, especially on the highway.

- Enhanced Off-Road Articulation: Components with advanced joint designs (like flex joints) allow for greater suspension travel, keeping tires on the ground and improving traction over uneven terrain.

- Increased Durability & Strength: Aftermarket parts are typically built much stronger than OEM, resisting damage from impacts, flex, and the stresses of larger tires.

- Corrected Suspension Geometry: Crucial for lifted Jeeps, adjustable arms and track bars ensure proper alignment, preventing premature wear on tires and other components.

- Mitigation of "Death Wobble": Often, worn or incorrect front control components are primary contributors to this dangerous condition. Upgrading can effectively eliminate it.

- Reduced NVH (Noise, Vibration, Harshness): While some performance joints can increase NVH, high-quality, well-designed components with sealed joints can actually reduce it compared to worn-out stock parts.

Key Considerations When Buying "Jeep Front Control For Sale"

Before making a purchase, ask yourself these crucial questions:

- Your Jeep Model & Year: Components are specific to Jeep models (Wrangler JK, JL, TJ, YJ, XJ, ZJ, etc.) and even year ranges. Ensure compatibility.

- Lift Height: This is the most critical factor. Fixed arms might work for mild lifts (under 2.5 inches), but adjustable arms are almost always required for 2.5 inches and above to correct geometry.

- Intended Use:

- Daily Driver/Mild Off-Roader: Prioritize comfort, longevity, and less maintenance (e.g., rubber or poly bushings, standard steel).

- Moderate to Hardcore Off-Roader: Prioritize strength, articulation, and durability (e.g., chromoly, flex joints).

- Material & Joint Type: Choose based on your intended use and budget. Chromoly and flex joints are top-tier but come at a premium.

- Brand Reputation & Warranty: Stick with reputable brands known for quality and customer support. Research reviews and warranty policies. Key players include TeraFlex, MetalCloak, Rock Krawler, Synergy, Rough Country, Rubicon Express, and JKS.

- Budget: Prices vary significantly. Set a realistic budget and be prepared to invest in quality, as these are critical safety and performance components.

Choosing the Right "Front Control" Components: A Step-by-Step Guide

- Assess Your Needs: Are you replacing worn parts, lifting your Jeep, or seeking performance upgrades? What are your driving habits (on-road vs. off-road ratio)?

- Determine Your Current/Desired Lift Height: This dictates whether you need fixed or adjustable arms, and the necessary range of adjustment.

- Research Brands and Product Types: Look into the various options offered by leading manufacturers. Compare their construction, joint types, and adjustability.

- Read Reviews and Seek Advice: Consult online forums, social media groups, and local Jeep clubs. Experienced owners can offer invaluable real-world feedback.

- Consider a Complete System: Many manufacturers offer full control arm kits (e.g., 8-piece sets including upper and lower, front and rear). This ensures compatibility and often offers cost savings over buying individual components.

- Don’t Forget Related Components: If you’re upgrading control arms for a lift, you’ll likely need an adjustable track bar. Consider upgrading tie rods, drag links, and ball joints if you run larger tires or off-road aggressively.

Installation Overview

Installing Jeep front control components, particularly control arms, can range from moderately challenging to complex.

- Tools: You’ll need standard mechanic’s tools, including wrenches, sockets, a torque wrench (crucial!), jack stands, and a floor jack. A spring compressor might be needed for some coil spring installations if other suspension components are being changed.

- Process (General): Involves safely supporting the vehicle, removing old components, installing new ones, and properly torquing all bolts to manufacturer specifications.

- Professional Installation: For those without significant mechanical experience, it’s highly recommended to have a professional shop (especially one specializing in Jeeps or off-road vehicles) handle the installation. Proper installation is vital for safety and performance.

- Alignment: After any major suspension work, a professional alignment is mandatory. This ensures correct caster, camber, and toe settings, preventing tire wear and ensuring optimal handling.

Potential Challenges and Solutions

- Cost: Quality components are an investment. Solution: Budget accordingly. Consider buying full kits for potential savings or upgrading in phases (e.g., front lowers first, then uppers, then rear).

- Complexity of Choice: The sheer number of options can be overwhelming. Solution: Thorough research, utilize online resources, and seek advice from experienced Jeepers or reputable shops.

- Installation Difficulty: It can be a labor-intensive job, especially if bolts are seized or rusted. Solution: If unsure, defer to professional installation. Always use penetrating oil on stubborn bolts.

- Post-Installation Issues: Poor alignment, noise, or unexpected handling characteristics. Solution: Ensure proper torque on all fasteners, get a professional alignment immediately, and be prepared to troubleshoot if issues persist. Many reputable manufacturers offer technical support.

Concluding Summary

"Jeep Front Control For Sale" represents a critical category of aftermarket components essential for any Jeep owner, particularly those looking to lift their vehicle, enhance its off-road prowess, or simply restore its original handling characteristics. From the fundamental role of control arms in setting axle geometry to the added benefits of heavy-duty steering linkages and track bars, these components are the backbone of a well-performing Jeep. Investing in quality front control parts ensures not only a safer and more enjoyable driving experience but also unlocks your Jeep’s full potential on any terrain. Do your research, choose wisely, and prepare to elevate your Jeep’s capabilities.

Estimated Price Table: Jeep Front Control Components For Sale

Please note: Prices are highly variable and depend on the specific Jeep model (e.g., JK, JL, TJ), brand, material, joint type, and retailer. The ranges below are estimates and should be used as a general guide. Always check current prices from reputable vendors.

| Component Type | Adjustability | Material | Joint Type(s) | Estimated Price Range (USD) | Key Benefit / Notes |

|---|---|---|---|---|---|

| Front Lower Control Arms (Pair) | Fixed | Steel | Rubber/Poly | $150 – $350 | Direct stock replacement, or mild lift correction. Simpler. |

| Front Lower Control Arms (Pair) | Adjustable | Steel | Poly/Flex Joint | $300 – $600 | Essential for lifted Jeeps (2.5"+), allows caster adjustment. |

| Front Lower Control Arms (Pair) | Adjustable | Chromoly | Flex Joint/Heim | $600 – $1000+ | Maximum strength & articulation for extreme off-road. |

| Front Upper Control Arms (Pair) | Fixed | Steel | Rubber/Poly | $120 – $300 | Stock replacement, less common for lift correction alone. |

| Front Upper Control Arms (Pair) | Adjustable | Steel | Poly/Flex Joint | $250 – $550 | Works with lowers to fine-tune caster after lift. |

| Front Upper Control Arms (Pair) | Adjustable | Chromoly | Flex Joint/Heim | $500 – $900+ | High-performance, often part of a full chromoly kit. |

| Complete Front Control Arm Kit (4 Arms) | Adjustable | Steel | Poly/Flex Joint | $600 – $1200 | Common upgrade for lifted Jeeps, ensures matched components. |

| Complete Front Control Arm Kit (4 Arms) | Adjustable | Chromoly | Flex Joint/Heim | $1200 – $2500+ | Premium kits for serious off-roaders, ultimate durability. |

| Adjustable Front Track Bar | Adjustable | Steel | Poly/Heim/Flex Joint | $180 – $450 | Re-centers front axle after lift, prevents bump steer. |

| Heavy-Duty Tie Rod | Fixed | Steel | Stock/Heim | $200 – $500 | Stronger than OEM, reduces bending, improves steering feel. |

| Heavy-Duty Drag Link | Fixed | Steel | Stock/Heim | $200 – $500 | Stronger than OEM, complements heavy-duty tie rod. |

| Heavy-Duty Ball Joints (Set of 4) | N/A | Forged Steel | Greaseable/Non-greaseable | $250 – $600+ | Replaces worn OEM, handles larger tires and off-road stress. |

Frequently Asked Questions (FAQ) about Jeep Front Control

Q1: What is "Death Wobble" and how do front control components relate to it?

A1: Death Wobble is a violent, uncontrollable shaking of the front end of a Jeep, usually triggered by hitting a bump at speed. It’s often caused by a combination of loose or worn steering and suspension components. Worn or improperly set control arms, a loose track bar, and worn ball joints are common culprits. Upgrading to quality, properly adjusted front control components is a primary solution.

Q2: Do I need adjustable control arms if I only lift my Jeep 2 inches?

A2: For a 2-inch lift, some owners opt for fixed, slightly longer control arms, or even retain stock arms if the lift kit includes caster correction brackets. However, adjustable control arms always offer the best solution as they allow for precise caster adjustment, optimizing handling and preventing potential issues even with smaller lifts. For lifts 2.5 inches and above, adjustable arms are highly recommended, if not mandatory.

Q3: What’s the difference between a Heim joint and a flex joint?

A3: Heim joints (spherical rod ends) offer maximum articulation and strength, but they are typically unsealed, can be noisy, and require more maintenance. Flex joints (like Currie Johnny Joints or TeraFlex FlexArms) are proprietary designs that often combine high articulation with better sealing, less noise, and reduced maintenance, making them a popular choice for a balance of on-road comfort and off-road performance.

Q4: Can I install control arms myself, or should I get professional help?

A4: If you have a good set of tools, mechanical aptitude, and a detailed service manual or reliable online guides, it’s a DIY-able project. However, it requires proper safety precautions (jack stands!), knowledge of torque specifications, and patience. If you’re unsure, or if bolts are seized, professional installation is recommended to ensure safety and proper functionality. An alignment must be done after installation.

Q5: How often do I need to replace my front control arms?

A5: The lifespan varies greatly depending on driving conditions, off-road frequency, and component quality. Stock arms might last 50,000-100,000 miles, but off-roading can significantly reduce that. Aftermarket arms, especially those with rebuildable joints, can last much longer with proper maintenance. Regularly inspect your components for wear, play, or damage.

Q6: Should I buy a full control arm kit or individual arms?

A6: For lifted Jeeps, a full 8-piece adjustable control arm kit (front and rear uppers/lowers) is often the best choice. It ensures all components are designed to work together, simplifies the purchase process, and can sometimes be more cost-effective. However, if you only need to replace a single worn arm, buying individual components is an option.

Q7: Will new control arms fix my steering wander or loose steering feel?

A7: Worn control arm bushings can contribute to steering wander and a loose feel by allowing the axle to shift. Upgrading to new, quality control arms will significantly improve this. However, other components like the track bar, ball joints, tie rod, drag link, and steering box also play a role, so a full diagnosis of the front end is always recommended.