Jeep In A Box For Sale: Your Blueprint to Building an Icon

Jeep In A Box For Sale: Your Blueprint to Building an Icon jeeps.truckstrend.com

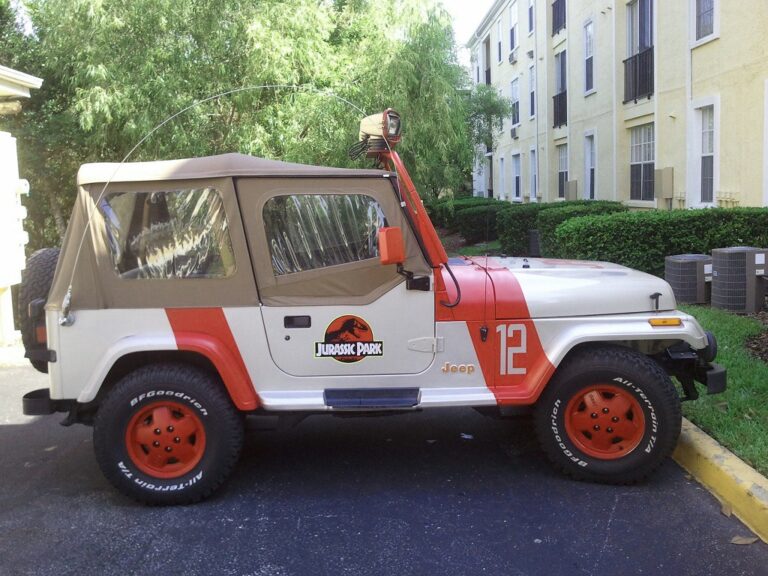

The rumble of a classic Jeep engine, the open-air freedom, the unmistakable silhouette – for many, it’s a dream. But finding a well-preserved vintage Jeep can be an expensive, time-consuming quest, often leading to a restoration project fraught with hidden rust and mechanical woes. Enter the "Jeep In A Box" – a concept that has captivated automotive enthusiasts, DIYers, and classic vehicle lovers for decades. This isn’t just about buying a vehicle; it’s about embarking on a journey, a hands-on adventure to build your very own piece of automotive history, component by component.

A "Jeep In A Box" typically refers to a comprehensive kit that provides most, if not all, the necessary parts to assemble a replica of a classic Jeep, most commonly the iconic Willys MB, CJ-2A, or CJ-3A. Imagine receiving multiple crates, each packed with meticulously manufactured new components: a sturdy frame, freshly stamped body panels, suspension parts, drivetrain elements, and even electrical systems. This concept offers an unparalleled opportunity to understand the mechanics of a vehicle from the ground up, to customize it to your exact specifications, and to forge a unique bond with the machine you bring to life. For those with a passion for mechanics, a desire for a truly bespoke vehicle, or simply the dream of owning a "new" classic without the headache of extensive restoration, a Jeep In A Box presents an incredibly appealing, and often more cost-effective, alternative.

Jeep In A Box For Sale: Your Blueprint to Building an Icon

What Exactly is a "Jeep In A Box"? Unpacking the Concept

At its core, a "Jeep In A Box" is a kit car, specifically designed to recreate the look and feel of vintage Jeep models. While the term might conjure images of a single, massive crate, it’s usually a collection of carefully packed boxes and pallets containing major sub-assemblies and individual parts.

Typical Components Included in a Full Kit:

- Chassis/Frame: A brand-new, robust frame designed to original specifications, often with improvements for modern safety or drivability.

- Body Panels: All exterior body panels, including the tub (main body), fenders, hood, grille, windshield frame, and tailgate. These are usually bare steel, ready for prep and paint.

- Suspension System: Leaf springs, shock absorbers, shackles, and mounting hardware.

- Steering System: Steering box, column, linkage, and wheel.

- Drivetrain Options: This is where kits vary. Some offer complete new engine and transmission packages (e.g., reproduction Go-Devil engines, modern four-cylinders, or V6 options with appropriate transmissions and transfer cases). Others might provide engine/transmission mounts and expect the builder to source their own powertrain.

- Axles: Front and rear axle assemblies, often complete with differential, brakes, and hubs.

- Braking System: Master cylinder, brake lines, calipers/drums, and pedal assembly.

- Fuel System: Fuel tank, lines, and often a fuel pump.

- Electrical System: A complete wiring harness, gauges, lights, and switches.

- Miscellaneous Hardware: Nuts, bolts, washers, clips, and small brackets to assemble everything.

What’s Typically Not Included (and why it matters):

- Paint and Bodywork Supplies: While panels are included, the final finish is up to the builder. This involves sanding, priming, painting, and clear coating.

- Upholstery/Interior Details: Seats often come as bare frames or simple cushions, requiring custom upholstery. Other interior trim might be minimal.

- Tires and Wheels: Usually sold separately, allowing the builder to choose their preferred style and size.

- Fluids: Engine oil, transmission fluid, brake fluid, coolant – all need to be purchased.

- Specialized Tools: While basic hand tools suffice for much of the build, specialized items like a cherry picker for the engine, a transmission jack, or a flaring tool for brake lines may be needed.

- Labor: The core appeal is the DIY aspect, so labor costs are zero, but your time investment is significant.

![]()

Understanding these inclusions and exclusions is crucial for budgeting and planning your build. It’s not just the "box" price; it’s the total cost of bringing your vision to life.

Why Embark on the "Jeep In A Box" Adventure? The Benefits

Choosing to build a Jeep from a kit is a decision driven by a unique set of advantages:

- Unparalleled Customization: From the moment you uncrate the first component, you are the master builder. You choose the paint color, the engine, the interior materials, the suspension setup, and every accessory. This isn’t just a classic Jeep; it’s your classic Jeep, built precisely to your specifications and desires.

- Deep Mechanical Understanding: Assembling a vehicle from scratch offers an incredible learning experience. You’ll gain an intimate knowledge of how every system works, from the steering linkage to the electrical harness. This understanding empowers you for future maintenance and troubleshooting.

- Cost-Effectiveness (Potentially): While the initial kit price can seem substantial, it often compares favorably to buying a fully restored vintage Jeep or undertaking a comprehensive restoration on a neglected donor vehicle. You save significantly on labor costs, and you avoid the "hidden surprises" (extensive rust, seized components) often found in old vehicles.

- Nostalgia and Authenticity: These kits are designed to replicate the original vehicles, allowing you to own a "new" classic that looks and feels authentic, but with the reliability of new components. You get the iconic styling without inheriting decades of wear and tear.

- Availability and Quality: Finding a truly solid, unmolested vintage Jeep can be incredibly difficult. Kit manufacturers produce new components with modern manufacturing techniques, ensuring consistency, fitment, and often improved material quality compared to their original counterparts.

- The Pride of Creation: There’s an immense sense of accomplishment that comes with building a vehicle with your own hands. Every bolt tightened, every wire connected, contributes to a functional, beautiful machine. It’s a passion project that culminates in a drivable masterpiece.

Navigating the Market: Types of Kits and Where to Find Them

The "Jeep In A Box" market isn’t monolithic. Understanding the different types of kits can help you choose the right path for your project:

- Full Turn-Key Kits: These are the most comprehensive, including virtually everything needed down to the engine and transmission. They are designed for a complete ground-up build.

- Body Kits: If you already have a donor chassis or frame, a body kit provides all the new body panels to create a pristine exterior. This is ideal for those restoring a specific vehicle’s VIN or using an existing rolling chassis.

- Rolling Chassis Kits: These kits include the frame, suspension, axles, and sometimes steering and braking systems, providing a solid foundation for you to add your preferred engine, transmission, and body.

- Component Bundles: Some suppliers don’t offer a single "kit" but allow you to purchase major component groups (e.g., frame and body, or engine and transmission package) that are commonly combined for a build.

Where to Find "Jeep In A Box" Kits:

- Specialized Kit Manufacturers: Companies like MD Juan, Omix-ADA (though primarily parts suppliers, they offer many components that can constitute a kit), and various smaller, independent fabricators specialize in reproduction Jeep parts and complete kits.

- Online Marketplaces: While rare, you might find kits listed on specialty vehicle sites, forums, or classifieds.

- Direct from Manufacturers/Importers: Many kits are manufactured overseas (e.g., Philippines for Willys reproduction parts) and imported by distributors. Researching these importers is key.

- Auto Shows and Swap Meets: Occasionally, kit providers or enthusiasts selling unfinished projects might be found here.

Thorough research into the reputation of suppliers, the quality of their components, and the level of support they offer is paramount before making a significant investment.

The Journey of Assembly: What to Expect and How to Prepare

Building a Jeep from a box is a significant undertaking, requiring space, tools, patience, and a methodical approach. It’s less of a sprint and more of a marathon.

Essential Requirements:

- Dedicated Workspace: A garage or workshop with ample space is crucial. You’ll need room to lay out parts, move around the chassis, and safely work on different sections.

- Tools: Beyond basic hand tools (wrenches, sockets, screwdrivers), you’ll likely need:

- Torque wrench

- Grinder and sander (for body prep)

- Welder (for minor fabrication or reinforcing)

- Air compressor and pneumatic tools

- Engine hoist/cherry picker

- Jack stands and floor jack

- Brake line flaring tool

- Electrical crimpers and multimeter

- Mechanical Aptitude: While not strictly necessary to be a master mechanic, a basic understanding of automotive systems and a willingness to learn are vital.

- Patience and Persistence: There will be frustrating moments. Parts might not fit perfectly, instructions might be vague, or you might hit a technical snag. Persistence is key.

Phases of the Build (General Overview):

- Inventory and Organization: Before starting, unpack and meticulously inventory all components against the packing list. Organize parts logically to avoid searching later.

- Frame Assembly & Suspension: Begin by assembling the frame, then install the leaf springs, shocks, and axles. This creates a rolling chassis.

- Drivetrain Installation: Mount the engine, transmission, and transfer case onto the frame. Connect the driveshafts.

- Braking and Fuel Systems: Install brake lines, master cylinder, and connect the fuel tank and lines.

- Body Mounting & Prep: Mount the body tub, fenders, hood, and grille onto the chassis. This is where significant time will be spent on bodywork: sanding, filling, priming, and painting.

- Electrical Wiring: Install the wiring harness, connect lights, gauges, and accessories. This requires careful attention to detail.

- Interior and Finishing Touches: Install seats, dashboard components, windshield, and other interior trim. Add any desired accessories like winches, bumpers, or custom lighting.

- Fluids and Initial Startup: Fill all fluids, perform a thorough check of all systems, and prepare for the initial engine startup.

- Testing and Tuning: Once running, perform initial tests, adjust timing, carburetor (if applicable), and ensure all systems are functioning correctly.

Time Commitment: Realistically, a full "Jeep In A Box" build can take anywhere from 6 months to 2 years for a dedicated individual working in their spare time. Full-time builders might complete it faster, but unexpected challenges are common.

Important Considerations Before You Buy

Before committing to a "Jeep In A Box," ponder these critical factors:

- Total Budget: The kit price is just the beginning. Factor in tools, paint, tires, wheels, upholstery, fluids, potential upgraded components, and contingency funds for unforeseen issues. A good rule of thumb is to budget 20-30% more than the kit’s cost for these incidentals.

- Legal and Registration Requirements: Kit car laws vary significantly by state and country. You’ll need to understand how to obtain a VIN, title, and register your newly built vehicle. This might involve inspections, special forms, or even "reconstructed" vehicle classifications. Research this before you buy!

- Resale Value: While a beautifully built kit Jeep can fetch a decent price, it typically won’t command the same value as a meticulously restored original vehicle with a verifiable history. It’s more of a personal project than an investment in terms of market appreciation.

- Supplier Support: Choose a supplier known for excellent customer service, clear instructions, and readily available technical support. You’ll likely have questions during the build.

- Storage and Logistics: Where will the crates be stored upon arrival? Where will you build the Jeep? Consider the space needed for parts, tools, and the vehicle itself throughout the process.

Challenges and Solutions

No major project is without its hurdles. Being prepared for potential challenges can save you headaches and keep your motivation high.

- Missing or Incorrect Parts:

- Solution: Immediately contact your supplier with clear documentation (photos, part numbers). A reputable supplier will rectify the issue quickly. Keep meticulous records of your inventory.

- Technical Difficulties/Unfamiliarity:

- Solution: Don’t be afraid to ask for help! Online forums, dedicated Jeep building communities, local mechanics, and even YouTube tutorials are invaluable resources. Break down complex tasks into smaller, manageable steps.

- Motivation Slump:

- Solution: It’s common to lose steam on long projects. Set small, achievable milestones and celebrate them. Take breaks. Remind yourself of the end goal: a custom-built classic Jeep.

- Financial Overruns:

- Solution: Stick to your budget, but always have a contingency fund. Prioritize essential components. Consider sourcing some parts used if quality isn’t compromised.

Price Table: Representative Costs for "Jeep In A Box" Kits (Estimates)

Please note: These prices are highly variable based on supplier, included components, quality, and market fluctuations. They are estimates for kits designed to build classic Willys/CJ-style Jeeps and do not include shipping, taxes, or the "extra" costs discussed above (paint, tires, tools, etc.).

| Kit Type / Inclusions | Estimated Price Range (USD) | Key Components Typically Included | Not Included / Builder Sourced | Ideal For |

|---|---|---|---|---|

| Basic Body & Frame Kit | $5,000 – $8,000 | New frame, complete bare body tub, fenders, hood, grille, windshield frame. | Engine, transmission, axles, suspension, steering, brakes, electrical, interior, paint. | Builder with existing drivetrain/chassis or who wants full control over component sourcing. |

| Rolling Chassis Kit | $8,000 – $15,000 | New frame, complete suspension (leaf springs, shocks), axles (often complete with brakes), steering box & linkage. | Engine, transmission, transfer case, body, electrical, interior, paint, tires/wheels. | Builder who wants a solid foundation and to choose their powertrain and body. |

| Near-Complete Kit (No Powertrain) | $15,000 – $25,000 | Frame, complete body (bare), full suspension, axles, steering, braking system, fuel tank, complete wiring harness, gauges, lights. | Engine, transmission, transfer case, tires/wheels, paint, upholstery, minor finishing hardware. | Builder with specific engine/transmission in mind, or who can source a good used unit. |

| Full Turn-Key Kit (with Basic Powertrain) | $25,000 – $40,000+ | All components of "Near-Complete Kit" PLUS a new or rebuilt reproduction engine (e.g., Go-Devil or modern 4-cyl), matching transmission & transfer case. | Tires/wheels, paint, upholstery, final assembly fluids. | Builder seeking the most comprehensive package for a complete ground-up build. |

Important Note: "Complete" in the kit world often means "complete enough to assemble." Always verify the exact contents with the supplier before purchase. Higher-end kits might include more finished components (e.g., pre-assembled axles, more detailed interior parts).

Frequently Asked Questions (FAQ)

Q: Is a "Jeep In A Box" kit street legal?

A: Generally, yes, but it depends heavily on your local regulations. Most kits are designed to meet basic safety standards. However, you will need to register it as a "specially constructed vehicle" or "kit car," which involves specific inspection processes and VIN assignment. Research your local Department of Motor Vehicles (DMV) or equivalent agency’s requirements thoroughly before starting your build.

Q: How long does it typically take to build one?

A: For an individual working in their spare time, a realistic timeframe is 6 months to 2 years. Factors like your skill level, available tools, dedicated workspace, and the complexity of the kit (and any custom modifications) will influence the duration.

Q: Do I need specialized tools?

A: While many tasks can be done with standard garage tools, having access to an engine hoist, transmission jack, air tools, a good torque wrench, and potentially a brake line flaring tool will make the process much smoother and safer.

Q: Can I customize it further than what the kit provides?

A: Absolutely! Customization is one of the biggest appeals. You can upgrade suspension, engine, interior, add aftermarket accessories, or create a unique paint scheme. The kit provides the foundation; your imagination is the limit.

Q: What’s the cheapest way to get a "Jeep In A Box"?

A: The cheapest route usually involves buying a basic body and frame kit and sourcing all other components (engine, transmission, axles, etc.) separately, often from donor vehicles or used parts. However, this requires significant research, knowledge, and time to find compatible and reliable components.

Q: What engine options are typically available or recommended?

A: Many kits are designed for reproduction Go-Devil L-head engines for authenticity. However, popular modern swaps include GM 2.5L Iron Duke, Ford 2.3L, or various small V6 engines for more power and reliability. Ensure the kit’s frame and mounts are compatible with your chosen engine.

Conclusion

The "Jeep In A Box" represents more than just a purchase; it’s an invitation to a unique and deeply rewarding automotive adventure. It’s an opportunity to bypass the rust and uncertainty of vintage restorations, and instead, craft a bespoke, "new" classic Jeep with your own hands. From the satisfying clang of metal as you bolt the frame together, to the triumphant roar of the engine on its first start, every step of the build is a testament to skill, patience, and passion.

While the journey demands commitment, research, and a healthy dose of mechanical aptitude, the end result is a truly personal vehicle – a timeless icon reborn, infused with your effort and vision. Owning a Jeep built from a box isn’t just about driving; it’s about the profound satisfaction of creation, the knowledge gained, and the enduring connection to a machine you brought to life, one component at a time. For the discerning enthusiast, the "Jeep In A Box" isn’t just for sale; it’s an experience waiting to be built.