Jeep JK Wheels For Sale: A Comprehensive Buyer’s Guide

Jeep JK Wheels For Sale: A Comprehensive Buyer’s Guide /jeeps.truckstrend.com

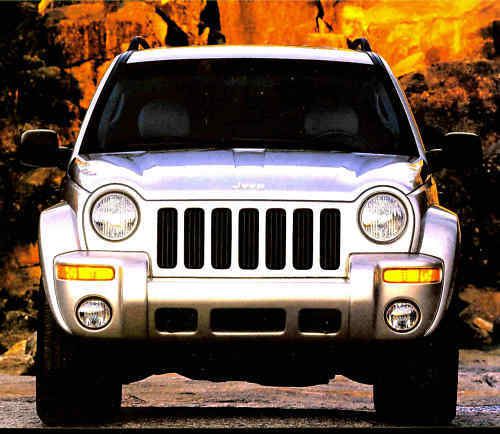

The iconic Jeep Wrangler JK, produced from 2007 to 2018, holds a special place in the hearts of off-road enthusiasts and daily drivers alike. Known for its rugged capability and unmatched customization potential, the JK platform offers a canvas for owners to express their unique style and enhance performance. Among the most impactful modifications one can make are the wheels. Whether you’re looking to upgrade your aesthetics, accommodate larger tires, improve off-road prowess, or simply replace a damaged set, the market for Jeep JK wheels for sale is vast and varied.

This comprehensive guide will delve into everything you need to know about navigating the world of JK wheels, from understanding critical specifications and types to finding the best deals and making an informed purchase. Upgrading your wheels isn’t just about looks; it’s about optimizing your Jeep’s stance, handling, and ability to conquer any terrain, making the right choice paramount for any JK owner.

Jeep JK Wheels For Sale: A Comprehensive Buyer’s Guide

Why Upgrade or Replace Your JK Wheels?

Before diving into the specifics, it’s essential to understand the motivations behind seeking out new wheels for your Jeep JK.

- Aesthetic Enhancement: This is often the primary driver. Factory wheels, while functional, can be mundane. Aftermarket wheels offer an incredible array of styles, finishes (black, chrome, polished, bronze, etc.), and designs that can dramatically transform your JK’s appearance, giving it a more aggressive, classic, or custom look.

- Accommodating Larger Tires: One of the most common JK modifications is upgrading to larger tires for increased ground clearance and off-road capability. Larger tires often require wheels with specific dimensions, particularly in terms of backspacing and width, to prevent rubbing against suspension components or fender flares during articulation.

- Improved Off-Road Performance: Wheels designed for off-roading are often stronger, more durable, and can feature technologies like beadlocks (or simulated beadlocks) that allow for lower tire pressures without the risk of the tire bead separating from the rim, enhancing traction on challenging terrain.

- Weight Reduction: Lighter wheels (typically forged or certain alloy designs) can reduce unsprung weight, potentially improving handling, ride quality, and even slightly boosting fuel efficiency.

- Replacing Damaged or Worn Wheels: Over time, wheels can suffer damage from curb rash, off-road impacts, or corrosion. Replacing them restores safety and appearance.

- Personalization and Uniqueness: Your Jeep is an extension of your personality. Unique wheels ensure your JK stands out from the crowd.

Understanding Jeep JK Wheel Specifications: The Essentials

Before you start browsing Jeep JK wheels for sale, it’s crucial to grasp the key specifications that dictate fitment and performance. Getting these wrong can lead to serious issues, from rubbing to unsafe driving conditions.

- Bolt Pattern (PCD): 5×5 (or 5x127mm)

- This is non-negotiable. The JK uses a 5-lug pattern with a 5-inch (127mm) bolt circle diameter. Any wheel you consider MUST have this exact bolt pattern.

- Diameter: Common sizes include 16", 17", 18", 20"

- This refers to the overall diameter of the wheel in inches. Smaller diameters (15-17 inches) are often preferred for off-roading as they allow for more tire sidewall, providing better cushioning and flex. Larger diameters (18-20 inches) tend to be more popular for street-oriented builds, offering a more aggressive look with lower-profile tires.

- Width: Common widths range from 8" to 10"

- This is the measurement from bead seat to bead seat. The wheel width must be appropriate for the tire width you plan to run. Too narrow or too wide a wheel for a given tire can compromise handling, wear, and safety.

- Backspacing: Critical for Tire Clearance

- Backspacing is the distance from the mounting surface of the wheel (where it bolts to the hub) to the back edge of the wheel.

- Why it matters: Lower backspacing (e.g., 3.5" to 4.5") pushes the wheel and tire further out from the vehicle. This is often necessary for larger tires (especially 35" and up) to clear suspension components (like control arms) and allows for a wider, more aggressive stance. Factory JK wheels typically have around 6.25" backspacing.

- Offset: Another measure of wheel position

- Offset is the distance from the wheel’s mounting surface to the true centerline of the wheel.

- Positive Offset: The mounting surface is towards the front of the wheel, pulling the wheel inward towards the vehicle.

- Negative Offset: The mounting surface is towards the back of the wheel, pushing the wheel outward from the vehicle.

- For JKs, especially with larger tires, you’ll often be looking for wheels with negative offset or low positive offset (which corresponds to lower backspacing) to achieve proper clearance.

- Center Bore: 71.5mm

- This is the hole in the center of the wheel that fits over the hub. A properly sized center bore ensures the wheel is centered on the hub, preventing vibrations. While wheels often have a larger center bore and rely on lug nuts for centering, a hub-centric fit is always preferred.

Types of Jeep JK Wheels

The materials and designs of Jeep JK wheels for sale vary widely, each offering different characteristics.

- Steel Wheels:

- Pros: Very durable, inexpensive, easy to repair (bend back into shape), often used for off-roading or winter setups.

- Cons: Heavy, limited aesthetic options, prone to rust.

- Alloy Wheels (Cast):

- Pros: Most common type, lighter than steel, wide variety of designs and finishes, good heat dissipation for brakes.

- Cons: Can crack or bend under severe impact, more difficult to repair than steel.

- Forged Alloy Wheels:

- Pros: Strongest and lightest type of alloy wheel, excellent performance characteristics.

- Cons: Most expensive option.

- Beadlock Wheels:

- True Beadlocks: Feature an outer ring that clamps the tire bead onto the wheel, allowing for extremely low tire pressures (e.g., 5-8 PSI) for maximum traction off-road without the tire separating from the rim.

- Pros: Unmatched off-road performance in challenging conditions.

- Cons: Often not DOT-approved for street use (check local laws), require more maintenance (re-torquing bolts), more expensive.

- Simulated Beadlocks (Cosmetic Beadlocks): Look like true beadlocks but the outer ring is purely decorative.

- Pros: Get the rugged look without the legality or maintenance issues of true beadlocks.

- Cons: No functional benefit for low tire pressures.

- True Beadlocks: Feature an outer ring that clamps the tire bead onto the wheel, allowing for extremely low tire pressures (e.g., 5-8 PSI) for maximum traction off-road without the tire separating from the rim.

Where to Find Jeep JK Wheels For Sale

The market for used and new Jeep JK wheels for sale is robust. Here are the best places to look:

- Online Marketplaces:

- Facebook Marketplace & Local Jeep Groups: Excellent for finding local deals. Many Jeep owners upgrade frequently, selling their lightly used wheels.

- Craigslist: Similar to Facebook Marketplace, good for local pickup.

- eBay: Wider selection, but factor in shipping costs. Be cautious with sellers without good ratings.

- Dedicated Jeep Forums (e.g., JK-Forum.com, WranglerForum.com): Often have "For Sale" sections where enthusiasts sell parts directly to others.

- Specialty Off-Road Shops: Many brick-and-mortar and online off-road retailers sell new wheels. Some might also take trade-ins or have used sets.

- Tire Shops: Sometimes have used wheels from trade-ins.

- Salvage Yards/Junkyards: Can be a gamble, but sometimes you find OEM wheels at a very low price. Inspect thoroughly for damage.

- Manufacturer Websites/Retailers: For new wheels, direct from brands like Fuel Off-Road, Method Race Wheels, KMC, Black Rhino, Quadratec, ExtremeTerrain, etc.

Key Considerations When Buying Used JK Wheels

When looking at Jeep JK wheels for sale, especially used ones, thorough inspection and careful consideration are vital.

- Condition is King:

- Visual Inspection: Look for deep scratches, curb rash (cosmetic but can indicate neglect), chips, and especially cracks. Cracks, even hairline ones, are a deal-breaker.

- Bends and Dents: A bent wheel can cause vibrations, premature tire wear, and even catastrophic failure. If possible, have the seller spin the wheel on a balancer to check for wobbles or bends.

- Corrosion/Rust: On steel wheels, surface rust is common, but deep pitting can compromise integrity. On alloy wheels, look for oxidation under the finish.

- Lug Hole Damage: Inspect the lug nut seats for stripping, elongation, or cracks, which can be dangerous.

- Completeness: Do the wheels come with center caps? Lug nuts? TPMS (Tire Pressure Monitoring System) sensors? These can add significant cost if purchased separately.

- Price vs. Value: Compare the asking price to the cost of new wheels of the same brand and type. Factor in condition. A heavily discounted price for a damaged wheel isn’t a good deal.

- Seller Reputation: If buying online, check seller reviews. If meeting in person, trust your gut.

- Tires Included? If the wheels come with tires, inspect the tires thoroughly: tread depth, even wear, sidewall cracks, age (DOT date code), and any patches or plugs. A good deal on wheels can turn sour if the tires are junk.

Practical Tips for a Successful Purchase

- Know Your Needs & Specs: Before you even start looking, decide on your desired wheel diameter, width, and crucially, the backspacing/offset required for your specific tire size and lift.

- Research Brands: Familiarize yourself with reputable wheel brands known for quality and durability.

- Ask Detailed Questions: Don’t be afraid to ask the seller about the wheels’ history, why they’re selling them, any known damage, and if they’ve ever been repaired.

- Request High-Resolution Photos/Videos: If buying remotely, ask for detailed photos of any imperfections, close-ups of the lug holes, and even a video of the wheel spinning if possible.

- Inspect In Person (If Possible): This is ideal. Bring a straight edge or a tape measure to check for bends or wobbles.

- Negotiate Respectfully: Most sellers of used items expect some negotiation. Be fair and reasonable.

- Budget for Extras: Remember to factor in potential costs for new lug nuts, TPMS sensors, mounting, balancing, and shipping.

- Verify Bolt Pattern: Bring a tape measure or a lug nut to confirm the 5×5 bolt pattern.

Challenges and Solutions

- Finding the "Perfect" Set: The exact brand, style, and specs you want at the right price can take time.

- Solution: Be patient and set up alerts on marketplaces.

- Hidden Damage: Some damage might not be obvious from photos.

- Solution: Always inspect in person if feasible. If not, request videos of the wheel spinning on a balancer or detailed close-ups. Consider a professional inspection after purchase.

- Scams: Online marketplaces can have dishonest sellers.

- Solution: Use secure payment methods (e.g., PayPal Goods & Services). Meet in well-lit public places. Never pay with gift cards or wire transfers. If a deal seems too good to be true, it probably is.

- Shipping Costs: Can be prohibitive for large, heavy items like wheels.

- Solution: Prioritize local pickup. If shipping, get a firm quote upfront and factor it into your budget.

Price Table: Representative Costs for Jeep JK Wheels For Sale

Please note that these prices are estimates and can vary significantly based on brand, condition, location, demand, and whether tires are included. Prices are generally for a set of four wheels, unless specified.

| Category | Material | Diameter (in) | Width (in) | Backspacing (in) | Typical Price Range (Set of 4) | Notes |

|---|---|---|---|---|---|---|

| OEM Used (Factory) | Alloy/Steel | 16-18 | 7.5-8.5 | 5.5-6.25 | $200 – $600 | Good for replacements, basic look. Often includes tires (check condition). |

| Aftermarket Used (Steel) | Steel | 15-17 | 8-9 | 3.75-4.75 | $250 – $500 | Durable, heavy, often for off-road or winter. Basic designs (e.g., D-window, Soft 8). |

| Aftermarket Used (Alloy) | Cast Alloy | 16-20 | 8-10 | 3.5-5.5 | $400 – $1,200 | Most common used aftermarket. Wide variety of styles. Price depends heavily on brand and condition. |

| Aftermarket Used (Premium) | Forged Alloy | 17-20 | 8.5-9.5 | 3.5-4.5 | $1,000 – $2,500 | High-end brands (e.g., Method, KMC, Fuel). Often lighter and stronger. Can include true beadlocks (if so, price likely higher). |

| New Aftermarket (Entry) | Cast Alloy | 17-18 | 8-9 | 4.5-5.0 | $600 – $1,000 | Brand new basic aftermarket wheels (e.g., Pro Comp, Black Rock). |

| New Aftermarket (Premium) | Cast/Forged | 17-20 | 8.5-10 | 3.5-4.5 | $1,200 – $3,000+ | Brand new high-quality or specialized wheels. Price can go much higher for true beadlocks or custom forged sets. |

| Single Replacement Wheel | Varies | Varies | Varies | Varies | $50 – $300+ | For replacing a single damaged wheel. Price depends on type, brand, and availability. |

Frequently Asked Questions (FAQ) about Jeep JK Wheels

Q1: What is the most important specification for JK wheels?

A1: The bolt pattern (5×5 or 5x127mm) is non-negotiable. After that, backspacing is crucial for tire clearance, especially if you’re running larger tires.

Q2: Can I put 20-inch wheels on my Jeep JK?

A2: Yes, many JK owners run 20-inch wheels. However, they typically require lower-profile tires, which means less sidewall for off-roading and a harsher ride. Ensure the wheel’s width and backspacing are compatible with your chosen tire size.

Q3: Do I need new lug nuts when buying aftermarket wheels?

A3: Often, yes. Aftermarket wheels sometimes require different lug nut seat types (e.g., conical vs. spherical) or sizes than factory lug nuts. It’s best to confirm with the wheel manufacturer or seller.

Q4: What’s the ideal backspacing for a lifted JK running 35-inch tires?

A4: For 35-inch tires on a lifted JK, a backspacing of 4.5 inches or less (e.g., 3.75" to 4.5") is commonly recommended to prevent rubbing on control arms and allow for proper articulation.

Q5: Are true beadlock wheels street legal?

A5: In most jurisdictions, true beadlock wheels are not DOT-approved for street use due to their design (requiring frequent re-torquing of bolts) and the potential for failure if not properly maintained. Always check your local regulations. Simulated beadlock wheels are fine as they are purely cosmetic.

Q6: How can I tell if a used wheel is bent or cracked?

A6: Visually inspect for obvious dents or cracks. If possible, spin the wheel on a tire balancer or even on the vehicle (carefully jacked up) to look for wobbles. Run your hand along the inner and outer lips to feel for inconsistencies. Severe bends or cracks usually mean the wheel is unsafe and should be avoided.

Q7: Should I buy wheels that already have tires mounted?

A7: This can be a great deal, but inspect the tires meticulously. Check the tread depth, look for uneven wear (indicating alignment issues), sidewall cracks, and the DOT date code (tires older than 5-6 years, even with good tread, can start to degrade). Factor in the cost of dismounting old tires and mounting new ones if the included tires aren’t suitable.

Conclusion

The market for Jeep JK wheels for sale offers an exciting opportunity to transform your Wrangler’s appearance and enhance its performance. Whether you’re chasing aggressive off-road capability, a sleek street presence, or simply a fresh look, understanding the critical specifications like bolt pattern, diameter, width, and especially backspacing is paramount. By knowing where to look, how to inspect used wheels, and what questions to ask, you can confidently navigate the myriad of options.

Remember, your wheels are a fundamental component of your vehicle’s safety and performance. Invest time in research and inspection, and don’t compromise on quality for a low price. With the right set of wheels, your Jeep JK will not only stand out from the crowd but will also be better equipped to tackle any adventure you throw its way. Happy hunting, and enjoy customizing your iconic JK!