Jeep Nutserts For Sale: Your Ultimate Guide to Fastening Solutions

Jeep Nutserts For Sale: Your Ultimate Guide to Fastening Solutions jeeps.truckstrend.com

The world of Jeep ownership is one of adventure, customization, and often, a bit of hands-on repair. From mounting essential off-road accessories like light bars and rock sliders to repairing corroded body panels or stripped bolt holes, Jeep enthusiasts frequently encounter situations where robust, reliable fastening solutions are paramount. This is where Jeep Nutserts For Sale enter the picture, transforming what could be complex fabrication or repair tasks into manageable, DIY-friendly projects.

Nutserts, also known as rivet nuts or blind rivet nuts, are ingenious threaded inserts designed to provide strong, load-bearing threads in materials that are too thin to tap, or in locations where you can only access one side of the material. For Jeep owners, this means the ability to add secure mounting points to body panels, roll cages, or frame components without welding, complex internal bracing, or disassembling large sections of the vehicle. Whether you’re upgrading your rig, restoring a classic, or simply needing a reliable fix, understanding and sourcing the right Jeep nutserts can be a game-changer. This comprehensive guide will delve into everything you need to know about these versatile fasteners, helping you navigate the market and make informed purchasing decisions.

Jeep Nutserts For Sale: Your Ultimate Guide to Fastening Solutions

Understanding Jeep Nutserts: A Foundation

At their core, a nutsert is a tubular rivet that is internally threaded. When installed with a specialized tool, the nutsert collapses, or "rivets," on the blind side of the material, creating a strong, permanent thread. This process is similar to how a pop rivet works, but instead of creating a solid connection, it leaves a threaded insert ready to accept a bolt.

For Jeeps, nutserts are particularly valuable because many components, like fenders, interior panels, and even some frame sections, are made from relatively thin sheet metal. Tapping threads directly into such material often results in weak, easily stripped connections. Nutserts provide a robust alternative, distributing the load over a larger surface area and offering superior pull-out and torque-out resistance.

Common materials for nutserts include:

- Steel (Zinc-Plated or Black Oxide): The most common and cost-effective option, offering good strength and basic corrosion resistance.

- Stainless Steel (304 or 316): Superior corrosion resistance, ideal for exposed areas or marine environments, though typically more expensive and slightly less strong than steel.

- Aluminum: Lightweight and corrosion-resistant, suitable for aluminum panels where galvanic corrosion is a concern.

Nutserts also come in various head styles (flat, large flange, countersunk) and body types (round, knurled, hexagonal), each offering specific advantages depending on the application and desired finish.

The Indispensable Role of Nutserts in Jeep Life

The demand for Jeep nutserts for sale stems directly from their incredible utility across a spectrum of applications unique to the Jeep lifestyle:

- Accessory Mounting: This is perhaps the most common use. Want to mount a light bar to your cowl, a hi-lift jack to your tailgate, or interior Molle panels for gear storage? Nutserts allow you to create strong, secure mounting points without drilling through multiple layers or accessing the back side of the panel. This is crucial for adding things like fender flares, rock sliders, or roof racks where robust attachment is key.

- Repairing Stripped Threads: Over time, especially in rust-prone areas or due to overtightening, original bolt holes in a Jeep’s body or frame can become stripped. Instead of welding a new nut or patching the hole, a nutsert can be installed into an enlarged, clean hole, effectively creating a brand-new, stronger thread. This is a common fix for door hinges, seat mounts, or body mount points.

- Custom Fabrication and Fabrication: For those building custom components, nutserts offer flexibility. They allow you to create custom mounting points on existing structures or fabricated parts where traditional welding is not feasible or desired. This is invaluable for creating removable parts or adding features to painted or powder-coated surfaces without damaging the finish.

- Corrosion Resistance: By choosing stainless steel nutserts, Jeep owners can proactively combat corrosion in high-exposure areas, ensuring longevity for their modifications and repairs.

- Clean and Professional Finish: When properly installed, nutserts offer a clean, flush, or low-profile finish, contributing to a professional appearance for any modification.

Navigating the Types of Jeep Nutserts For Sale

When looking for Jeep nutserts for sale, you’ll encounter a variety of options. Understanding these types is crucial for selecting the right one for your specific needs:

By Material

- Zinc-Plated Steel Nutserts: These are the workhorses, offering a good balance of strength and cost. The zinc plating provides a basic level of corrosion protection.

- Black Oxide Steel Nutserts: Similar to zinc-plated but with a black finish, often used for aesthetic reasons or where a slightly more robust finish is desired.

- 304 Stainless Steel Nutserts: Excellent for general outdoor use, offering good resistance to rust and many chemicals. A popular choice for exposed exterior parts.

- 316 Stainless Steel Nutserts: Superior corrosion resistance compared to 304, especially in saltwater or highly corrosive environments. Ideal for Jeeps frequently exposed to harsh elements or beach driving.

- Aluminum Nutserts: Lighter than steel or stainless, and useful for aluminum body panels to prevent galvanic corrosion (which occurs when dissimilar metals are in contact). They are softer and have lower pull-out strength than steel.

By Head Type

- Flat Head (Low Profile): The most common type, providing a flush or nearly flush finish with the surface.

- Large Flange Head: Features a wider flange that spreads the load over a larger area, making it ideal for softer materials or oversized holes, and offering increased pull-out resistance.

- Countersunk Head: Designed to sit completely flush with the surface when installed in a countersunk hole, offering the cleanest possible finish.

By Body Type

- Round Body: Standard and most common. Requires a precisely drilled hole.

- Knurled/Ribbed Body: Features ridges or knurling on the body to increase spin-out resistance, making it more secure once installed.

- Hexagonal Body: Provides the highest spin-out resistance as it requires a hexagonal hole, preventing rotation entirely. This is ideal for high-torque applications.

By Grip Range

Crucially, nutserts are designed for specific material thicknesses, known as their "grip range." Always verify that the nutsert’s grip range matches the thickness of the material you’re installing it into. An incorrect grip range can lead to improper installation, loose connections, or nutsert failure.

Choosing the Right Nutsert: A Buyer’s Guide

When you’re browsing Jeep nutserts for sale, consider these key factors to ensure you get the perfect fit for your project:

- Application and Load: What are you mounting? A heavy-duty bumper or a lightweight interior panel? This dictates the required strength and material. For structural or high-load applications, consider steel or stainless steel with a knurled or hex body.

- Material Thickness: Measure the thickness of the material you’re installing the nutsert into. This is paramount for selecting a nutsert with the correct grip range.

- Thread Size: What size bolt do you plan to use? Nutserts are available in common SAE (e.g., 1/4-20, 5/16-18, 3/8-16) and Metric (e.g., M6, M8, M10) thread sizes. Ensure compatibility with your existing or planned hardware.

- Corrosion Resistance: If the nutsert will be exposed to moisture, road salt, or other corrosive elements, stainless steel (304 or 316) is a wise investment.

- Aesthetics: Do you need a flush finish (countersunk) or is a low-profile head acceptable (flat head)?

- Tool Compatibility: Do you have the appropriate nutsert installation tool for the size and type of nutsert you plan to buy? Some kits come with a basic tool, while heavier-duty applications might require a dedicated tool.

DIY Installation: A Quick Overview

While the focus here is on Jeep nutserts for sale, it’s important to understand the installation process, as it directly impacts your purchasing decisions (e.g., needing a tool).

Tools Required:

- Nutsert Installation Tool: This is indispensable. Options range from simple manual hand tools to more powerful pneumatic or electric tools for high-volume or larger nutsert installations.

- Drill: For drilling the pilot hole.

- Drill Bits: Precisely sized for the nutsert’s body diameter (usually specified by the nutsert manufacturer).

- Deburring Tool: To clean the edges of the drilled hole, ensuring proper nutsert seating.

- Measuring Tools: Calipers or a ruler for material thickness and hole diameter.

Basic Installation Steps:

- Mark and Drill: Mark the location and drill the correct size hole. Accuracy here is key – too small, and the nutsert won’t fit; too large, and it will spin.

- Deburr: Clean the edges of the hole to remove any sharp burrs.

- Insert Nutsert: Thread the nutsert onto the mandrel of the installation tool.

- Position and Compress: Insert the nutsert into the drilled hole. Squeeze the handles of the tool (or activate the pneumatic/electric mechanism) to compress the nutsert. You’ll feel it collapse and seat firmly.

- Remove Tool: Carefully unthread the tool’s mandrel from the now-installed nutsert.

Proper compression is vital. Too little, and the nutsert won’t be secure; too much, and you can damage the nutsert or the material.

Where to Find Jeep Nutserts For Sale: Your Sourcing Guide

The market for Jeep nutserts for sale is diverse, offering options for every budget and project size:

- Online Retailers:

- General Marketplaces: Amazon, eBay, and Walmart often carry a wide selection of nutserts in various sizes and materials, usually in multi-packs or small kits.

- Industrial Suppliers: McMaster-Carr, Fastenal, Grainger are excellent sources for high-quality, specialized nutserts, often available in bulk.

- Specialized Fastener Websites: Many online stores focus solely on fasteners, offering a broader range of less common sizes or materials.

- Jeep-Specific Parts Retailers: Websites like Quadratec, ExtremeTerrain, and Northridge4x4 sometimes offer nutsert kits tailored for specific Jeep applications, often bundled with necessary hardware.

- Local Automotive and Hardware Stores: While their selection might be limited, you can sometimes find basic nutsert kits or small packs for common sizes.

- Specialty Fastener Stores: If you have a local store that specializes in bolts, nuts, and other fasteners, they often have a deep inventory of nutserts and can provide expert advice.

- Off-Road and Fabrication Shops: Local shops that specialize in custom vehicle builds or off-road modifications often stock nutserts and may be able to advise on the best type for your project.

When buying, consider whether you need a small quantity for a single repair or a larger bulk pack for ongoing projects. Bulk purchases often offer significant cost savings per unit.

Maximizing Value: Tips for Buying Jeep Nutserts

- Read Reviews: Especially for kits or bulk packs, reviews can provide insights into the quality of the nutserts and the included installation tool.

- Verify Specifications: Double-check the material, thread size, head type, and most importantly, the grip range before purchasing.

- Consider a Kit: If you’re new to nutserts or need various sizes for different projects, a nutsert kit (often including an assortment of nutserts and a basic installation tool) can be a cost-effective starting point.

- Buy a Few Extra: It’s always a good idea to have a few spares, especially for common sizes. Installation errors or future repairs might require them.

- Don’t Skimp on Quality: While budget-friendly options exist, extremely cheap nutserts can be made of inferior materials or have poor manufacturing tolerances, leading to frustration during installation or premature failure.

Common Challenges and Solutions

Even with the right Jeep nutserts for sale, issues can arise. Here are some common problems and their solutions:

- Spin-out: The nutsert spins in the hole during installation or when trying to thread a bolt.

- Solution: Ensure the hole is the correct size – too large is a common cause. Use a nutsert with a knurled or hexagonal body for increased spin-out resistance. Ensure sufficient compression during installation.

- Stripped Internal Threads (Nutsert): The threads inside the nutsert strip when tightening a bolt.

- Solution: Avoid overtightening. Use a torque wrench if precision is needed. If it happens, you may need to drill out the old nutsert and install a larger one, or switch to a nutsert made of a stronger material.

- Corrosion: The nutsert rusts prematurely.

- Solution: Use stainless steel nutserts (304 or 316) in exposed or high-moisture areas. Apply anti-corrosion coatings or lubricants during installation.

- Improper Compression: The nutsert isn’t fully collapsed or is over-compressed.

- Solution: Ensure you’re using the correct nutsert tool for the specific nutsert size. Follow the tool’s instructions for proper compression. Practice on scrap material first.

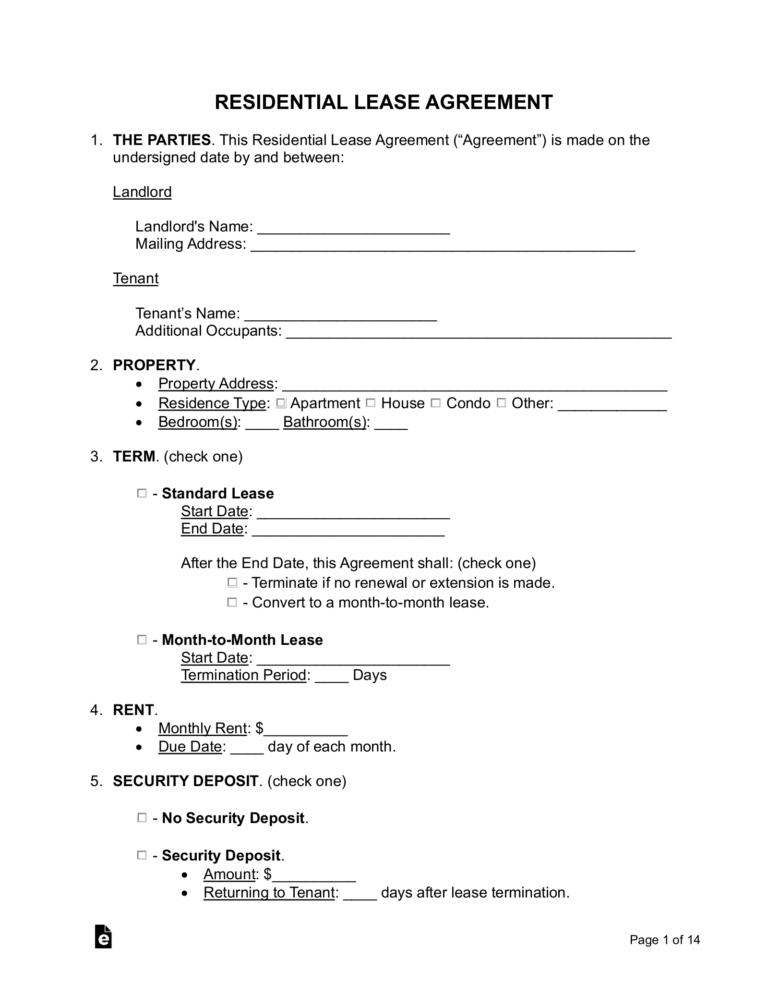

Price Table: Illustrative Costs for Jeep Nutserts For Sale

Please note that prices for nutserts can vary significantly based on material, thread size, head type, brand, vendor, and quantity purchased (e.g., single units vs. bulk packs of 100 or 1000). The table below provides estimated price ranges for common Jeep nutserts for sale and related tools. These are for illustrative purposes only and actual market prices may differ.

| Nutsert Type (Material, Head) | Thread Size (Common) | Typical Quantity | Estimated Price Range (USD) | Notes |

|---|---|---|---|---|

| Steel, Flat Head, Zinc-Plated | 1/4-20 | 50-pack | $10 – $25 | Most common, general purpose |

| Steel, Flat Head, Zinc-Plated | 5/16-18 | 50-pack | $12 – $30 | Good for medium-duty applications |

| Steel, Flat Head, Zinc-Plated | M8 | 50-pack | $10 – $25 | Common metric size |

| Stainless Steel (304), Flat Head | 1/4-20 | 25-pack | $15 – $35 | Excellent corrosion resistance |

| Stainless Steel (304), Flat Head | M6 | 25-pack | $12 – $30 | For lighter duty, metric applications |

| Aluminum, Flat Head | M6 | 50-pack | $15 – $30 | Lightweight, good for aluminum panels |

| Steel, Large Flange Head, Knurled | 1/4-20 | 25-pack | $12 – $28 | Increased spin-out & pull-out resistance |

| Steel, Hex Body, Zinc-Plated | 5/16-18 | 25-pack | $18 – $38 | Highest spin-out resistance, requires hex hole |

| Manual Nutsert Tool | (Fits various sizes) | Each | $30 – $100 | Hand-operated, good for occasional use |

| Nutsert Tool Kit | (Assorted Nutserts + Tool) | Kit | $50 – $150 | Great for beginners, includes common sizes |

| Pneumatic/Electric Nutsert Tool | (Heavy Duty) | Each | $200 – $1000+ | For professional or high-volume use |

Disclaimer: All prices are estimates and subject to change based on vendor, brand, material quality, and market conditions.

Frequently Asked Questions (FAQ) about Jeep Nutserts For Sale

Q1: What’s the difference between a "nutsert" and a "rivet nut"?

A1: They are essentially the same thing. "Nutsert" is a brand name that has become a generic term, while "rivet nut" is the more general descriptor.

Q2: Do I need a special tool to install nutserts?

A2: Yes, absolutely. You need a dedicated nutsert installation tool (also called a rivet nut tool). This tool pulls the threaded mandrel, collapsing the nutsert to create the secure thread.

Q3: Can I use nutserts on my Jeep’s frame?

A3: Yes, nutserts can be used on frame components, especially for mounting accessories or repairing non-structural holes. However, for critical structural points or heavy-duty applications, ensure you select appropriately sized, high-strength steel or stainless steel nutserts with excellent spin-out resistance (e.g., hex body) and ensure proper installation. Always consult a professional if you’re unsure about structural modifications.

Q4: How do I know what size nutsert to buy?

A4: You need to consider two main factors:

- Thread Size: This must match the bolt you plan to use (e.g., 1/4-20, M8).

- Grip Range: This must match the thickness of the material you are installing the nutsert into. Always measure your material thickness carefully.

Q5: Are stainless steel nutserts always better than steel?

A5: Not always. Stainless steel offers superior corrosion resistance, which is excellent for exposed areas. However, stainless steel nutserts can be more expensive and generally have lower shear strength and are softer than zinc-plated steel nutserts. Choose based on the primary requirement: corrosion resistance or maximum strength.

Q6: What if a nutsert spins in the hole after I install it?

A6: A spinning nutsert indicates an improper installation. Common causes include:

- The drilled hole is too large.

- The nutsert was not adequately compressed.

- The nutsert type isn’t suitable for the application (e.g., using a plain round body in a high-torque situation).

- Solution: You may need to drill out the spinning nutsert, enlarge the hole, and install a larger nutsert, or use a nutsert with a knurled or hexagonal body for better spin-out resistance.

Conclusion

Jeep nutserts for sale represent an invaluable resource for every Jeep owner, from the casual enthusiast to the dedicated off-roader or restorer. These simple yet incredibly effective fasteners empower you to tackle a wide array of projects, from mounting crucial accessories to making robust repairs, all without the need for specialized welding equipment or extensive fabrication skills.

By understanding the different types of nutserts available, carefully choosing the right ones for your specific application, and mastering their proper installation, you unlock a new level of customization and repair capability for your Jeep. With the abundance of Jeep nutserts for sale online and in various retail outlets, acquiring these essential fasteners has never been easier. Invest wisely in quality nutserts and the appropriate tools, and you’ll find yourself confidently enhancing, repairing, and personalizing your Jeep for countless adventures to come.