Jeep Stroker Motors For Sale: Unleash the Power Within Your Off-Road Beast

Jeep Stroker Motors For Sale: Unleash the Power Within Your Off-Road Beast jeeps.truckstrend.com

For many Jeep enthusiasts, the rumble of a powerful engine is as much a part of the experience as the terrain itself. While the venerable inline-six (I6) 4.0L engine has long been a workhorse, its limitations can become apparent when tackling challenging trails, towing heavy loads, or simply desiring more spirited on-road performance. This is where the allure of a "Jeep Stroker Motor" comes into play. A stroker motor is, at its core, a modified version of an existing engine, typically the 4.0L or sometimes the 2.5L, that has been upgraded to increase its displacement, thereby generating significantly more horsepower and, crucially, torque.

The concept is simple: by installing a crankshaft with a longer "stroke" (the distance the piston travels up and down in the cylinder), along with matching connecting rods and pistons, the engine’s cubic inch displacement is increased. This boost in volume allows the engine to ingest and combust more air and fuel, resulting in a dramatic increase in power output. For those seeking to elevate their Jeep’s capabilities beyond stock, a stroker motor for sale represents a compelling and often transformative upgrade. This comprehensive guide will delve into everything you need to know about Jeep stroker motors, from their mechanics to where to find them and what to consider before making a purchase.

Jeep Stroker Motors For Sale: Unleash the Power Within Your Off-Road Beast

What Exactly is a Jeep Stroker Motor?

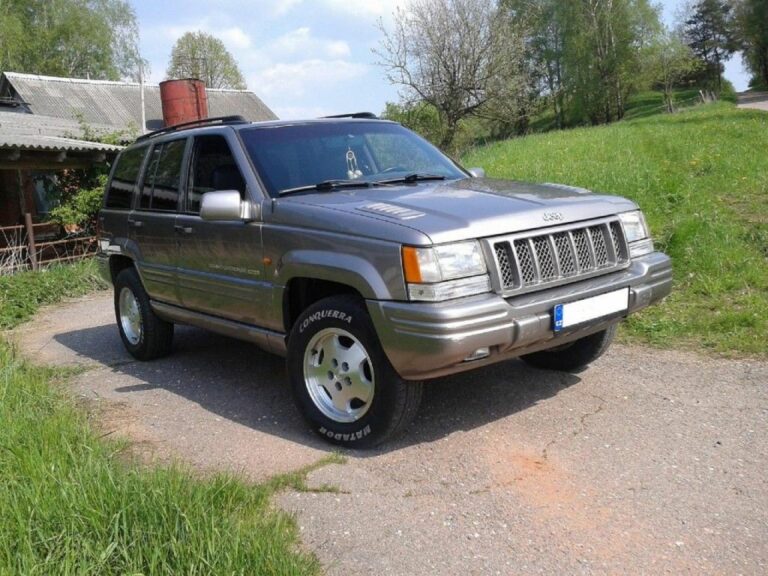

At its heart, a Jeep stroker motor is an engine that has undergone a specific internal modification to increase its displacement, and thus its power. The most common donor engine for this transformation is the legendary AMC 4.0L inline-six, found in popular Jeep models like the Cherokee (XJ), Wrangler (YJ/TJ/LJ), and Grand Cherokee (ZJ/WJ). Less frequently, the 2.5L I4 engine also receives the stroker treatment.

The modification primarily involves replacing the stock crankshaft with one that has a longer throw (or stroke). This longer stroke is often sourced from an earlier AMC 4.2L (258 cubic inch) engine, which shares the same main and rod journal sizes as the 4.0L. To accommodate the longer stroke, shorter connecting rods and/or different pistons are typically required to prevent them from hitting the cylinder head at the top of their travel. The result is an engine with a larger effective volume, allowing it to produce more power and, critically for Jeeps, more low-end torque. Common stroker displacements for the 4.0L range from 4.6L to 5.0L, with the 4.6L and 4.7L being the most popular due to their balance of power gain and reliability.

Why Choose a Stroker Motor for Your Jeep? (Benefits)

The decision to invest in a stroker motor is usually driven by a desire for enhanced performance. Here are the key benefits:

- Significant Power and Torque Gains: This is the primary draw. A well-built 4.6L or 4.7L stroker can easily add 50-100+ horsepower and even more torque over a stock 4.0L, with the most noticeable improvement being in low-end grunt. This is invaluable for off-roading, allowing your Jeep to crawl over obstacles with less throttle input.

- Improved Acceleration and Highway Performance: Beyond the trails, a stroker transforms your Jeep’s on-road manners. Merging onto highways becomes effortless, and maintaining speed on inclines is no longer a struggle.

- Better Towing Capability: The increased torque makes towing trailers, boats, or other vehicles significantly easier and safer, reducing strain on the drivetrain.

- Enhanced Reliability (When Built Correctly): Despite being a modified engine, a professionally built stroker can be as, if not more, reliable than a stock engine, especially if higher-quality components are used. Many builders focus on durability as much as performance.

- Retaining the Inline-Six Character: For many purists, the inline-six is integral to the Jeep experience. A stroker allows you to keep that distinctive character while vastly improving its capabilities, avoiding the complexities of an engine swap to a V8.

Types of Jeep Stroker Builds (Common Configurations)

![]()

Stroker builds vary in their specific component combinations and resulting displacement. Here are some of the most common and their characteristics:

- 4.6L Stroker: Often achieved by using the 4.0L block with the 4.2L crankshaft and stock 4.0L connecting rods, paired with custom pistons that compensate for the longer stroke. This is a popular and relatively cost-effective option, offering a good balance of power and reliability.

- 4.7L Stroker: Typically uses the 4.0L block, 4.2L crankshaft, and shorter aftermarket connecting rods (e.g., from a Chevy 5.7L) along with custom pistons. This combination usually yields slightly more displacement and power than the 4.6L and is highly regarded for its performance.

- 4.9L and 5.0L+ Strokers: These larger displacements often involve more extensive modifications, potentially including boring the cylinders to a larger diameter in addition to the stroke increase. They offer maximum power but might come with higher costs and potentially more specialized tuning requirements.

Stroker motors for sale are usually offered in two main forms:

- Short Block: This includes the engine block, crankshaft, connecting rods, and pistons assembled. It’s the "bottom end" of the engine. You would need to transfer your existing cylinder head, valvetrain, oil pan, timing cover, and accessories.

- Long Block: This is a more complete engine, including the assembled short block with a cylinder head (often re-manufactured or ported), valvetrain, and sometimes the oil pan and timing cover. This is a more "drop-in" solution, though you’ll still need to add accessories like the intake manifold, exhaust manifold, and alternator.

- Crate Engine: The most complete option, often including all necessary sensors, fuel injectors, and sometimes even a pre-tuned ECU, ready for installation. These are typically the most expensive but offer the greatest convenience.

Where to Find Jeep Stroker Motors For Sale

The market for Jeep stroker motors has grown significantly, offering various avenues for purchase:

- Specialized Engine Builders/Performance Shops: This is often the most recommended route. Companies like Golen Engine Service, ATK Engines, Titan Engines, and S&J Engines specialize in building high-performance Jeep strokers. They offer warranties, professional assembly, and often dyno-tested engines.

- Online Marketplaces (with caution): Websites like eBay, Facebook Marketplace, and dedicated Jeep forums (e.g., NAXJA, JeepForum) often have individuals or smaller shops selling stroker motors. While prices might be lower, vetting the seller’s reputation and understanding the engine’s history and components is crucial. Always ask for detailed photos, build sheets, and ideally, a video of it running if possible.

- Used Parts Dealers: Some larger salvage yards or used parts specialists might occasionally have stroker motors, but these are often unverified and carry significant risk.

- Custom Local Builders: Many experienced mechanics or engine shops can build a stroker to your specifications. This allows for a highly customized build but requires trust in their expertise and a clear understanding of the components and warranty.

When buying, prioritize reputable sellers who offer a warranty and can provide detailed information about the build, including the specific components used (e.g., brand of pistons, rods, camshaft).

Key Considerations When Buying a Jeep Stroker Motor

Purchasing a stroker motor is a significant investment. Here are vital factors to consider:

- Budget: Stroker motors vary widely in price based on displacement, components (forged vs. cast), builder reputation, and whether it’s a short block, long block, or complete crate engine. Be prepared for costs ranging from $2,500 for a basic short block to over $7,000 for a fully built, dyno-tested long block or crate engine.

- Intended Use: Will your Jeep be a daily driver, a dedicated rock crawler, or a high-speed desert runner? Your primary use will dictate the ideal power band, component strength, and tuning requirements. For serious off-roading, focus on low-end torque.

- Reputation of Seller/Builder: This cannot be stressed enough. A poor build can lead to costly failures. Look for reviews, forum discussions, and direct testimonials.

- Components Used: Inquire about the quality of internal components:

- Crankshaft: Is it a re-machined 4.2L crank or a new aftermarket one?

- Pistons & Rods: Are they forged or cast? Forged components are stronger and recommended for higher horsepower applications. Brands like Wiseco, Ross, Eagle, and Molnar are well-regarded.

- Camshaft: What grind is it? A custom grind can optimize power for your specific needs (e.g., more low-end torque for crawling).

- Cylinder Head: Is it a re-manufactured stock head, a ported stock head, or an aftermarket high-flow head?

- Tuning Requirements: A stroker motor will require a re-tune of your Jeep’s engine control module (ECM/PCM). The increased air and fuel flow necessitates recalibrating fuel maps and ignition timing. Many reputable builders offer a compatible ECU with their engines, or you’ll need a custom tune from a specialist.

- Ancillary System Upgrades:

- Fuel System: Larger fuel injectors are almost always necessary (typically 24-28 lb/hr for most strokers). A higher-flow fuel pump might also be beneficial.

- Cooling System: Increased power generates more heat. A heavy-duty radiator, upgraded water pump, and perhaps an auxiliary fan are highly recommended to prevent overheating.

- Exhaust System: A less restrictive exhaust manifold (header) and larger diameter exhaust system will allow the engine to breathe better and fully realize its power potential.

- Warranty: Understand what the warranty covers, its duration, and any conditions (e.g., professional installation required, specific break-in procedures).

- Shipping & Installation: Factor in the cost and logistics of shipping the engine and potential professional installation fees.

Installation and Post-Installation Tips

While some DIY enthusiasts tackle engine swaps, professional installation is highly recommended for a stroker motor due to its complexity and the precision required.

- Professional Installation: Ensures correct assembly, sensor connections, and initial startup procedures are followed.

- Break-in Procedures: Follow the engine builder’s specific break-in recommendations meticulously. This usually involves varying RPMs, avoiding sustained high RPMs, and changing oil after a specific mileage (e.g., 500 miles). This is crucial for piston ring seating and overall engine longevity.

- Proper Cooling System: Ensure your cooling system is in top shape or upgraded before running the new engine. An overheating stroker can quickly lead to damage.

- Fueling and Tuning: This is paramount. The engine must be properly tuned for its new displacement and airflow. Without correct fueling and timing, it will run poorly, inefficiently, or even suffer catastrophic damage.

- Drivetrain Considerations: The increased power and torque from a stroker will put more stress on your transmission, transfer case, driveshafts, and axles. While many stock drivetrains can handle a mild stroker initially, heavy off-road use or larger displacements may necessitate upgrades to stronger components down the line.

Potential Challenges and Solutions

- Cost: Stroker motors are not cheap. Solution: Save up, or explore financing options if available from reputable builders. Consider a short block first if budget is tight, then upgrade the top end later.

- Compatibility Issues: Ensuring the engine is compatible with your specific Jeep model and year’s wiring and accessory mounts. Solution: Buy from a builder who specializes in your Jeep model and explicitly states compatibility.

- Reliability Concerns: Fear of a shortened engine life. Solution: Purchase from highly reputable builders who use quality components and offer warranties. Adhere strictly to break-in and maintenance schedules.

- Emissions Compliance: Some regions have strict emissions laws. A modified engine might not pass visual inspections or tailpipe tests. Solution: Research your local laws thoroughly. Some builders offer emissions-compliant builds, but often, the benefits of a stroker might be curtailed.

- Drivetrain Strain: The new power can expose weaknesses in the rest of your drivetrain. Solution: Be prepared for potential future upgrades to your transmission, transfer case, and axles if you plan on aggressive driving or heavy loads. Start saving for these possibilities.

Price Table: Representative Jeep Stroker Motors For Sale

Please note: Prices are highly variable and depend on the builder, specific components used (forged vs. cast), warranty, current market conditions, and whether it’s a short block, long block, or complete crate engine. These are estimated ranges for general guidance.

| Displacement | Type | Key Features (Example) | Estimated Price Range (USD) | Notes |

|---|---|---|---|---|

| 4.6L | Short Block | Re-manufactured crank, new pistons/rods, balanced | $2,500 – $3,500 | Requires your head, valvetrain, oil pan, etc. Good entry point. |

| 4.6L | Long Block | Re-manufactured crank, new pistons/rods, re-man head | $3,500 – $5,000 | More complete, less assembly required by installer. |

| 4.7L | Short Block | 4.2L crank, aftermarket rods, forged pistons, balanced | $3,000 – $4,500 | Stronger components, better for demanding use. |

| 4.7L | Long Block | 4.2L crank, aftermarket rods, forged pistons, ported head | $4,500 – $6,500 | High performance, often includes a performance camshaft. |

| 4.9L+ | Long Block | Forged internals, bored block, custom cam, ported head | $6,000 – $8,500+ | Max performance, often requires more ancillary upgrades & advanced tuning. |

| All | Crate Engine | Complete engine with sensors, injectors, sometimes ECU | $7,000 – $10,000+ | Most convenient, "drop-in" solution. Varies widely by inclusions. |

Disclaimer: These prices are estimates only and do not include shipping, installation, or required ancillary upgrades (e.g., fuel injectors, cooling system, exhaust, tuning). Always get a detailed quote from your chosen builder.

Frequently Asked Questions (FAQ)

Q: Is a stroker motor reliable?

A: Yes, if built by a reputable professional using quality components and properly maintained, a stroker motor can be as reliable as, or even more reliable than, a stock engine. Problems usually arise from poor build quality or incorrect tuning.

Q: Do I need to upgrade my transmission?

A: Not necessarily immediately, especially for mild strokers and moderate use. However, the increased power and torque will put more strain on your transmission (AW4, AX15, NV3550, 42RE, etc.). For heavy off-roading, towing, or larger strokers, transmission upgrades (e.g., heavier-duty clutches, torque converter, valve body mods) or even a full swap to a stronger unit might be beneficial for long-term durability.

Q: Will a stroker motor pass emissions?

A: This depends heavily on your local and state emissions laws. In some areas, any engine modification that changes displacement is technically illegal for street use, or it might struggle to pass tailpipe tests. In other areas, as long as it has a catalytic converter and the check engine light is off, it might pass. Always check your local regulations before purchasing.

Q: What’s the best displacement for a Jeep stroker?

A: The 4.6L and 4.7L are generally considered the "sweet spot" for balancing power gains, reliability, and cost-effectiveness for the 4.0L I6. They provide a significant power boost without excessive stress on the engine block or requiring extreme ancillary upgrades.

Q: Can I build one myself?

A: Building a stroker motor requires significant engine building knowledge, specialized tools (e.g., for precise measurements, balancing), and access to a machine shop. While some highly experienced DIYers do it, for most, it’s safer and often more cost-effective in the long run to purchase a professionally built unit with a warranty.

Q: What’s the difference between a 4.6L and a 4.7L stroker?

A: The difference usually lies in the length of the connecting rods and sometimes the piston compression height. Both typically use the 4.2L crankshaft. A 4.6L often uses stock 4.0L rods with custom pistons, while a 4.7L typically uses shorter aftermarket rods (like Chevy 5.7L rods) and custom pistons, resulting in slightly more displacement and often a slightly different power curve.

Concluding Summary

A Jeep stroker motor for sale offers an exciting pathway to dramatically increase the performance of your beloved off-road machine. By leveraging the inherent strengths of the original inline-six platform, strokers deliver a substantial boost in horsepower and, more importantly for Jeep applications, torque, transforming everything from trail crawling to highway cruising.

While the investment is significant, the benefits in capability and driving enjoyment are undeniable. The key to a successful stroker experience lies in meticulous research, choosing a reputable builder, understanding the required ancillary upgrades, and ensuring proper installation and tuning. Armed with the knowledge from this guide, you can confidently navigate the market for Jeep stroker motors, making an informed decision that truly unleashes the beast within your Jeep.