Jeep TJ Frame For Sale: Your Comprehensive Guide to Restoration, Repair, and Rebirth

Jeep TJ Frame For Sale: Your Comprehensive Guide to Restoration, Repair, and Rebirth jeeps.truckstrend.com

The iconic Jeep Wrangler TJ (1997-2006) holds a special place in the hearts of off-road enthusiasts and casual drivers alike. Known for its rugged capability, classic design, and robust aftermarket support, the TJ is a true testament to Jeep’s enduring legacy. However, like any vehicle, time and the elements can take their toll, and for many TJ owners, the Achilles’ heel often proves to be the frame. Rust, accident damage, or even the desire for a stronger foundation for extreme builds can lead owners down a specific path: the search for a "Jeep TJ Frame For Sale."

This comprehensive guide is designed to be your go-to resource, whether you’re a seasoned mechanic contemplating a full frame swap, a DIY enthusiast battling rust, or simply exploring the possibilities for your beloved TJ. We’ll delve into everything from why you might need a new frame to where to find one, what to look for, and the critical considerations involved in this significant undertaking.

Jeep TJ Frame For Sale: Your Comprehensive Guide to Restoration, Repair, and Rebirth

Why Consider a Replacement TJ Frame? The Call to Rebirth

For many Jeep TJ owners, discovering severe frame rust can feel like a death sentence for their cherished vehicle. The frame is the backbone of your Jeep, providing structural integrity, mounting points for the suspension, engine, transmission, and body. When it’s compromised, safety, performance, and legality all come into question. But rust isn’t the only reason to seek a replacement frame.

Here are the primary motivations for searching for a Jeep TJ frame for sale:

- Severe Rust and Corrosion: This is by far the most common reason. TJs, especially those from rust-belt regions or coastal areas, are highly susceptible to frame rot, particularly in common areas like the rear control arm mounts, skid plate mounts, and behind the steering box. Once rust progresses beyond minor surface issues, repair can become impractical or unsafe.

- Accident Damage: A significant collision can bend, twist, or crack the frame beyond repair. While minor damage might be repairable by a specialist, severe deformation necessitates a full frame replacement to restore the vehicle’s structural integrity and alignment.

- Custom Builds and Upgrades: For those planning extreme off-road builds, engine swaps, or significant suspension modifications, a new, stronger, or even custom-fabricated frame might be desired. Aftermarket frames often offer thicker steel, improved geometry, or integrated features for specific applications.

- Salvage Title Restoration: If you’ve acquired a TJ with a salvage title due to frame damage, replacing the frame can be a viable path to getting it back on the road safely and legally.

- Preventive Maintenance/Future-Proofing: Some meticulous owners might opt for a frame swap on a relatively good body to ensure the long-term health and value of their Jeep, especially if they plan to keep it for many years to come.

Understanding the TJ Frame: Anatomy and Vulnerabilities

Before embarking on the search, it’s crucial to understand the basic construction of the Jeep TJ frame. It’s a ladder-style frame, meaning two main parallel rails connected by several crossmembers. This design offers excellent rigidity and off-road articulation.

Key Components and Common Rust Zones:

- Main Frame Rails: The long, rectangular tubes running front to back.

- Crossmembers: Connect the main rails, providing rigidity and mounting points for components like the transmission skid plate, transfer case, and fuel tank.

- Body Mounts: Points where the body bolts to the frame. These often trap dirt and moisture, leading to rust.

- Control Arm Mounts: Critical for suspension geometry. The rear upper and lower control arm mounts are notorious rust spots.

- Shock Mounts: Also prone to rust, especially where they meet the frame.

- Skid Plate Mounts: The bolts and surrounding frame areas for the transfer case skid plate are common rust areas.

- Steering Box Area: The frame section behind the steering box is a common stress point and rust trap.

- Rear Bumper/Hitch Area: Often exposed to road grime and moisture.

![]()

Understanding these vulnerable points will help you critically assess any potential replacement frame.

Types of TJ Frames Available: New, Used, and Refurbished

The market for TJ frames offers a few distinct options, each with its own benefits and drawbacks:

-

Used OEM (Original Equipment Manufacturer) Frames:

- Description: These are frames pulled from other TJ Jeeps, often from salvage vehicles, donor Jeeps, or those being parted out.

- Pros: Generally the most affordable option. Maintains original Jeep specifications.

- Cons: Condition varies wildly. Requires thorough inspection for rust, bends, and previous repairs. May still require some rust remediation or minor repair. Comes with a VIN that must be addressed legally.

- Best For: Budget-conscious owners looking for a direct replacement for a moderately damaged or rusted frame, willing to put in inspection effort.

-

Refurbished/Repaired OEM Frames:

- Description: Used OEM frames that have undergone professional rust removal, repair of damaged sections (often with new patch panels), and sometimes a protective coating.

- Pros: Better condition than raw used frames, often "ready to go" or requiring minimal prep. Repairs are typically done by experienced fabricators.

- Cons: More expensive than raw used frames. Quality of refurbishment can vary, so ensure the seller is reputable. Still carries the original VIN.

- Best For: Those who want the OEM fit but prefer a frame that’s already had significant rust/damage addressed.

-

New Aftermarket/Reproduction Frames:

- Description: Brand new frames manufactured by third-party companies (e.g., Throttle Down Kustoms, Chassis Unlimited). These are often built from thicker steel, may feature improved designs, or be prepped for specific engine/suspension setups.

- Pros: Brand new, no rust or damage. Often stronger than OEM. Can be customized during fabrication (e.g., stretched, custom mounts). No VIN issues from a donor vehicle.

- Cons: Significantly more expensive. May require more lead time for fabrication. Some minor fitment adjustments might be needed depending on the manufacturer.

- Best For: Serious builders, those seeking maximum durability, or owners who want a completely fresh start without any rust concerns.

Where to Find a Jeep TJ Frame For Sale

Finding the right frame requires diligence and knowing where to look:

- Online Marketplaces: Craigslist, Facebook Marketplace, eBay Motors. These are great for local finds but require careful vetting of sellers and in-person inspection.

- Jeep Forums & Enthusiast Groups: Dedicated TJ forums (e.g., WranglerForum.com, JeepForum.com) and Facebook groups often have "for sale" sections where members part out Jeeps. These communities can also offer valuable advice.

- Salvage Yards/Auto Recyclers: Large salvage yards often have complete vehicles or frames. Call ahead to inquire about TJ frames specifically and their inspection policies.

- Specialized Jeep Parts Dealers: Companies that specialize in used Jeep parts may have frames. They often inspect and store frames properly.

- Aftermarket Frame Manufacturers: If you’re opting for a new frame, contact companies like Throttle Down Kustoms (TDK), Chassis Unlimited, or similar fabricators directly.

What to Look For: Critical Inspection Points

This is arguably the most crucial step, especially when buying a used or refurbished frame. A thorough inspection can save you immense headaches and expense down the road.

- Rust, Rust, Rust: Don’t just look at the outside. Use a hammer to gently tap along the frame rails, especially in known rust areas. Listen for solid thuds; a dull thud or crunching sound indicates severe internal rust. Check inside the frame rails if possible. Pay close attention to:

- All control arm mounts (upper and lower, front and rear).

- Body mounts.

- Skid plate mounts.

- Shock mounts.

- Area around the steering box.

- The rear sections near the bumper and gas tank.

- Straightness and Alignment: Look down the length of the frame rails from both ends to ensure they are straight and not bent or twisted. Check for any signs of buckling, particularly around the front and rear sections where impacts might occur. Measure critical points (e.g., diagonal measurements from opposing corners) to verify it’s square.

- Cracks and Previous Repairs: Look for any visible cracks, especially near welds or stress points. Inspect any previous repair welds – are they professional and strong, or do they look like a backyard job?

- VIN Tag: The frame has a VIN tag. Ensure it’s present and legible. This is critical for legal transfer and registration.

- Overall Condition: Assess the overall cleanliness and care given to the frame. A frame that’s been stored outdoors on the ground will likely have more issues than one stored indoors on blocks.

Practical Advice: Always inspect in person if at all possible. Bring a flashlight, a small hammer, and a tape measure. If buying remotely, demand high-resolution photos and videos of specific areas, and consider hiring a local mechanic or inspector.

The Purchase Process and Logistics

Once you’ve found a suitable frame, consider these practicalities:

- Price Negotiation: Prices vary significantly based on type, condition, and location. Be prepared to negotiate, especially for used frames.

- Legalities and VIN Transfer: This is paramount. The frame has its own VIN. In many states, replacing the frame effectively means you’re building a new vehicle, or at least transferring the identity. You must understand your local Department of Motor Vehicles (DMV) or equivalent agency’s requirements for frame swaps and VIN transfers. This usually involves a VIN inspection and potentially a new title or a "reconstructed" title. Never buy a frame without a clear title or bill of sale that includes the VIN.

- Shipping/Transport: Frames are large and heavy. Factor in shipping costs if buying remotely. Local pickup with a flatbed trailer or large truck is often the most economical option. Discuss loading assistance with the seller.

Installation Considerations: A Major Undertaking

Swapping a Jeep TJ frame is not a trivial task. It’s a significant mechanical project that requires:

- Space: A large, level garage or shop.

- Tools: Engine hoist (for lifting the body), transmission jack, comprehensive socket and wrench sets, air tools, cutting tools (grinder, Sawzall), possibly welding equipment.

- Mechanical Aptitude: A solid understanding of automotive systems, disassembly, and reassembly.

- Time: This is not a weekend job. Plan for weeks, if not months, of dedicated effort.

- Assistance: It’s a two-person job at minimum for many stages, especially body removal and placement.

Challenges:

- Seized Bolts: Expect many bolts to be rusted solid, requiring heat, penetrating oil, or cutting.

- Wiring and Hoses: Disconnecting and reconnecting the entire wiring harness, fuel lines, brake lines, and steering components requires patience and careful labeling.

- Body Mounts: Old body mounts often need replacement.

- Unexpected Discoveries: Be prepared for additional repairs once you’ve separated the body from the frame.

Practical Advice: If you’re not confident in your abilities, consider professional installation. While expensive, it ensures the job is done correctly and safely. Document every step with photos for reassembly.

Frame Repair vs. Replacement: When to Choose Which

The decision between repairing your existing frame and replacing it entirely hinges on the extent of the damage:

- Repair is Viable When:

- Rust is localized to small, non-structural areas (e.g., small holes in the flat sections of the rails, minor rust on mounts).

- Damage is limited to a single, easily accessible crossmember or a minor bend that can be professionally straightened.

- The repair sections are readily available (e.g., Safe-T-Cap kits for common rust spots).

- The cost of repair, including labor, is significantly less than a replacement frame and swap.

- Replacement is Recommended When:

- Rust is widespread, affecting multiple structural components, or is deep within the frame rails.

- The frame is severely bent, twisted, or cracked in critical areas (e.g., main frame rails, steering box area).

- Multiple major repairs would be needed, making the overall integrity questionable.

- You desire a stronger, aftermarket frame for a custom build.

- The cost of extensive repairs approaches or exceeds the cost of a replacement frame plus the labor for a swap.

Practical Advice: Get multiple opinions from trusted fabricators or mechanics before making this critical decision.

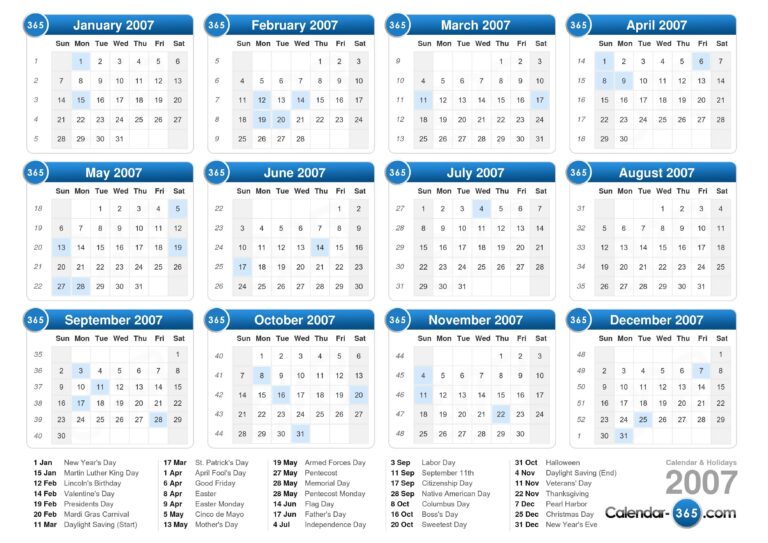

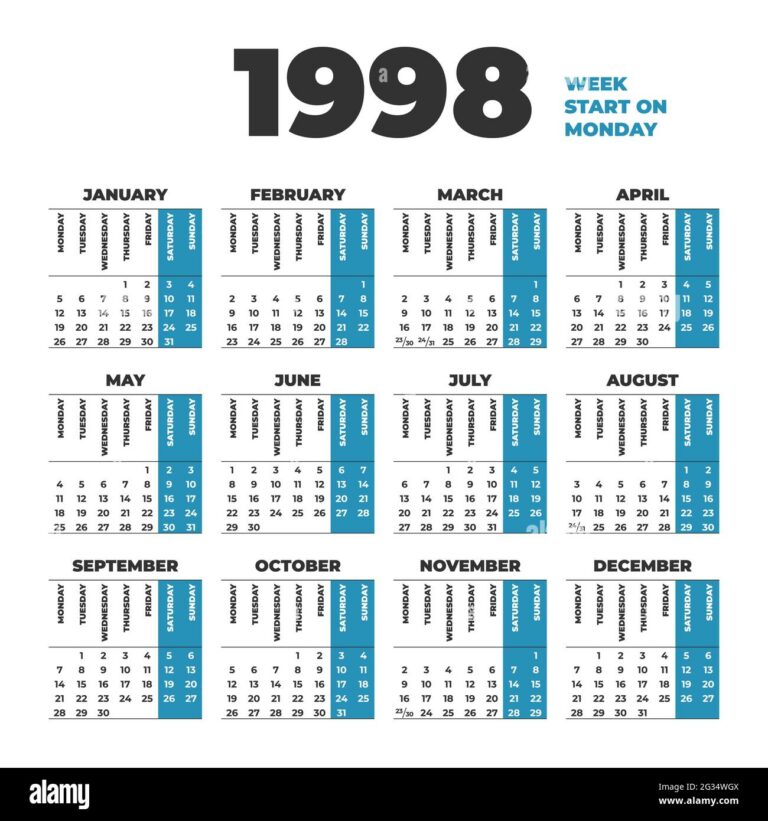

Pricing Guide: Jeep TJ Frames For Sale (Estimated)

Please note that these are estimated price ranges and can vary significantly based on location, seller, condition, demand, and economic factors. Always confirm current prices with sellers.

| Frame Type | Condition/Quality | Estimated Price Range (USD) | Key Considerations |

|---|---|---|---|

| Used OEM Frame | Poor/Heavy Rust: Requires significant repair | $300 – $700 | Primarily for parts, or for experienced fabricators willing to undertake major work. High risk. |

| Used OEM Frame | Fair/Moderate Rust: Needs patches, surface rust removal | $700 – $1,500 | Most common type found. Requires thorough inspection and likely some DIY rust remediation. |

| Used OEM Frame | Good/Minimal Rust: Solid, minor surface rust only | $1,500 – $2,500 | Hard to find. Often from dry climates or low-mileage vehicles. Best value for a direct swap. |

| Refurbished OEM Frame | Professionally Repaired: Cleaned, patched, coated | $2,500 – $4,500 | Less work for the buyer. Verify quality of repairs and reputation of the refurbisher. |

| New Aftermarket Frame | Standard Duty: Direct OEM replacement, thicker steel | $4,000 – $6,000+ | Brand new, no rust. Often stronger. May have slight design variations. |

| New Aftermarket Frame | Heavy Duty/Custom: Stretched, specific features | $6,000 – $10,000+ | For specialized builds. Price varies greatly with customization. Longer lead times. |

- Note: These prices typically do NOT include shipping costs, which can add hundreds to over a thousand dollars depending on distance and carrier.

Frequently Asked Questions (FAQ)

Q1: Does a Jeep TJ frame have a VIN?

A1: Yes, the Jeep TJ frame has a VIN (Vehicle Identification Number) stamped on it, typically near the front passenger side frame rail. This is crucial for legal purposes when swapping frames.

Q2: Is a new VIN required after a frame swap?

A2: This depends on your state or country’s laws. In many places, a frame swap is considered significant enough to require a VIN inspection and potentially a "reconstructed" or "assembled" title, or even the transfer of the original vehicle’s VIN to the new frame. Always check with your local DMV/equivalent agency before purchasing a frame.

Q3: How much does it cost to ship a TJ frame?

A3: Shipping costs vary widely but can range from $300 to $1,500 or more within the contiguous United States, depending on distance, carrier, and whether it’s shipped to a commercial or residential address.

Q4: Can I do a TJ frame swap myself?

A4: A TJ frame swap is a very involved project that requires significant mechanical skill, specialized tools (like an engine hoist), ample space, and a lot of time. While it’s certainly possible for a skilled DIY mechanic, it’s not recommended for beginners.

Q5: What years of TJ frames are interchangeable?

A5: Generally, all 1997-2006 TJ frames are dimensionally similar enough to be interchangeable, though there might be minor differences in bracketry for specific components (e.g., later models might have slight variations for ABS or other sensors). Always confirm with a knowledgeable source or by comparing part numbers if possible.

Q6: What’s the best way to protect a new or refurbished frame from rust?

A6: After thorough cleaning and preparation, apply a high-quality rust-inhibiting primer, followed by a durable topcoat (e.g., chassis paint, bed liner material). For even better protection, consider internal frame coating (e.g., Fluid Film, Eastwood Internal Frame Coating) and external rustproofing.

Conclusion

The search for a "Jeep TJ Frame For Sale" is often the first step in breathing new life into a beloved off-road companion. While it represents a significant investment of time, money, and effort, a successful frame swap can transform a rust-ridden relic into a structurally sound, capable, and reliable vehicle once again. By understanding the options available, diligently inspecting potential purchases, navigating the legal complexities, and preparing for the demands of the installation, you can ensure your Jeep TJ continues its adventures for many years to come. The journey of finding and installing a new frame is challenging, but the reward of a renewed TJ, ready for the trails, is truly priceless.