Jeep TJ Frames For Sale: Your Ultimate Guide to Restoring, Rebuilding, or Customizing Your Iconic Off-Roader

Jeep TJ Frames For Sale: Your Ultimate Guide to Restoring, Rebuilding, or Customizing Your Iconic Off-Roader jeeps.truckstrend.com

The Jeep Wrangler TJ, produced from 1997 to 2006, holds a special place in the hearts of off-road enthusiasts and automotive purists alike. Known for its rugged reliability, iconic design, and legendary off-road prowess, the TJ remains a highly sought-after vehicle. However, like any vehicle of its age, the TJ is not immune to the ravages of time, particularly when it comes to its foundation: the frame. For many TJ owners, especially those in regions prone to heavy road salt or challenging terrains, frame rust and damage are significant concerns. This is where the market for Jeep TJ frames for sale becomes incredibly relevant, offering a lifeline to countless restoration projects, custom builds, and repairs.

This comprehensive guide will delve deep into everything you need to know about Jeep TJ frames for sale, from understanding why you might need one to navigating the purchasing process, considering different types, and even touching on the complexities of frame replacement. Whether you’re a seasoned mechanic, a dedicated DIY enthusiast, or someone just starting their Jeep journey, this article aims to equip you with the knowledge to make informed decisions about securing the perfect foundation for your beloved TJ.

Jeep TJ Frames For Sale: Your Ultimate Guide to Restoring, Rebuilding, or Customizing Your Iconic Off-Roader

Why the Quest for Jeep TJ Frames For Sale?

The primary driver behind the demand for Jeep TJ frames for sale is often structural integrity. Decades of exposure to harsh elements, particularly road salt, can lead to severe frame rot. This isn’t just a cosmetic issue; it compromises the vehicle’s safety, handling, and overall longevity. Beyond rust, other common reasons include:

- Accident Damage: Collisions, even minor ones, can bend, twist, or crack the frame, rendering it unsafe or impossible to align properly.

- Off-Road Abuse: While TJs are built tough, extreme off-roading can lead to bent frame rails, cracked welds, or damaged mounting points from hard impacts or heavy loads.

- Restoration Projects: Many enthusiasts seek to fully restore TJs, bringing them back to factory-new condition, which often necessitates a pristine frame.

- Custom Builds & Engine Swaps: For those looking to build a highly customized TJ, perhaps with a larger engine or unique suspension setup, a new or robust frame provides the ideal starting point.

- Salvage Titles: A vehicle with a salvage title due to frame damage might be revitalized with a frame swap, making it roadworthy again.

Understanding these motivations highlights the critical role that a sound frame plays in the life of a Jeep TJ.

Navigating the Landscape of Jeep TJ Frames For Sale

When you begin your search for Jeep TJ frames for sale, you’ll encounter several categories, each with its own set of pros, cons, and price points. Understanding these distinctions is crucial for making the right choice for your project and budget.

1. Used OEM Frames

These are frames salvaged from other Jeep TJs, typically from vehicles that were totaled due to body damage, engine issues, or other non-frame-related problems.

- Pros: Generally the most affordable option. Maintains original factory specifications and mounting points, ensuring direct fitment.

- Cons: Condition varies wildly. High risk of hidden rust, previous repairs, or minor bends that are hard to detect without thorough inspection. Shipping can be expensive.

- Consideration: Requires meticulous inspection for rust, cracks, and alignment issues.

2. Refurbished/Restored OEM Frames

Some specialized shops or individuals acquire used OEM frames, then strip, repair, sandblast, and coat them. They often reinforce common weak points.

- Pros: Significantly improved condition over raw used frames. Rust-free and often prepped for paint/coating. Can save considerable prep time.

- Cons: Higher cost than raw used frames. Still based on used steel, so underlying issues might exist if not thoroughly addressed.

- Consideration: Verify the reputation of the refurbisher and the extent of the restoration process.

3. Aftermarket/New Reproduction Frames

These are brand-new frames manufactured by third-party companies, often using thicker steel or improved designs to address original TJ frame weaknesses.

- Pros: Brand new, no rust or hidden damage. Often built with stronger materials and better welds. Can be designed for specific upgrades (e.g., engine mounts for V8 swaps).

- Cons: The most expensive option. Fitment issues can occasionally arise, though reputable manufacturers strive for OEM-level accuracy. May require some fabrication for specific components depending on the design.

- Consideration: Research manufacturer reputation, material quality, and ensure compatibility with your specific TJ model year and desired build. Examples include Throttle Down Kustoms or Apex Chassis.

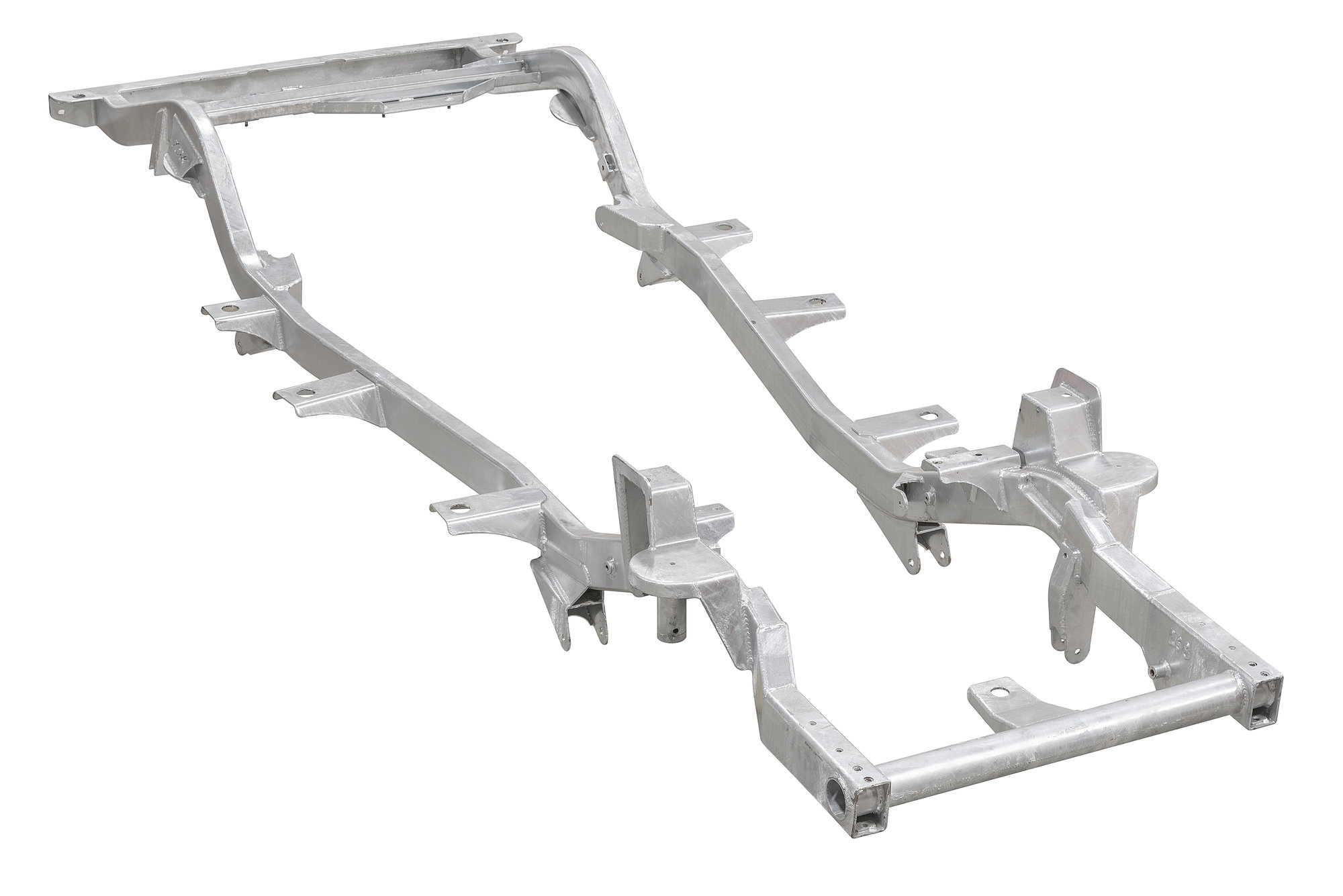

4. Galvanized Frames

A subset of new or refurbished frames, these are hot-dip galvanized after fabrication. This process coats the steel with a layer of zinc, providing superior corrosion resistance.

- Pros: Unparalleled rust protection, virtually eliminating future rust concerns. Ideal for vehicles in harsh environments.

- Cons: Significantly higher cost. The galvanized finish is distinctive and might not appeal to everyone aesthetically (though it can be painted). Limited availability in the US market, often imported.

- Consideration: The ultimate long-term solution for rust prevention, but a significant investment.

Key Considerations When Shopping for Jeep TJ Frames For Sale

Purchasing a frame is a major investment of time and money. Here are critical factors to scrutinize before making a commitment:

-

Rust, Rust, Rust: This is the TJ frame’s Achilles’ heel. Inspect every nook and cranny. Common rust-out spots include:

- The frame rails directly below the doors (body mounts 3 & 4).

- Behind the front tires, where mud and salt accumulate.

- The skid plate mounting points.

- Upper and lower control arm mounts.

- Spring perches.

- The rear crossmember.

- Inside the frame rails (use a borescope if possible).

- Look for flaking, bubbling, or soft spots. Tap with a hammer – a dull thud indicates rust.

-

Damage & Straightness: Look for bends, kinks, twists, or signs of collision repair. Check all mounting points (body, engine, transmission, suspension) for cracks, elongation, or deformation. A frame that isn’t straight will cause alignment issues, tire wear, and handling problems.

-

VIN & Paperwork: If buying a used frame, it will have a Vehicle Identification Number (VIN) stamped on it. Crucially, research your state’s regulations regarding frame swaps and VIN transfer. Some states require inspection, while others may issue a "reconstructed" title. Always get a bill of sale and ensure the VIN is clear and untampered with.

-

Included Components: Does the frame come bare, or does it include crossmembers, shock mounts, control arm mounts, or even the steering box? A bare frame will require more parts and labor.

-

Shipping & Logistics: Frames are large, heavy, and awkward. Freight shipping can be very expensive, sometimes costing as much as the frame itself. Factor this into your budget. Local pickup is ideal if possible.

-

Seller Reputation: Whether buying from an individual or a business, check reviews, ask for references, and ensure they are reputable. Request detailed photos and videos, and if possible, inspect the frame in person.

The Frame Swap Process: A Brief Overview

Replacing a TJ frame is a significant undertaking, not for the faint of heart or those without proper tools and space.

- Disassembly: This involves removing the body (often lifted off the frame), drivetrain (engine, transmission, transfer case), axles, suspension components, steering, and fuel tank.

- Preparation: The new frame needs to be prepped – cleaning, rustproofing, and painting are essential steps for longevity.

- Reassembly: The process is reversed, carefully transferring all components to the new frame. This requires precision, proper torque specifications, and often new hardware.

- Tools & Expertise: You’ll need a well-equipped garage, a lift or significant jack stands, an engine hoist, and a full range of mechanic’s tools. Experience with automotive systems is highly recommended.

- Professional Help: For many, having a professional shop handle the frame swap is the safest and most efficient route, though it will be costly due to the labor involved.

Tips for Finding the Best Deal on Jeep TJ Frames For Sale

- Online Marketplaces: eBay, Craigslist, and Facebook Marketplace are common places to find used frames. Use specific search terms like "Jeep TJ frame," "TJ rolling chassis," or "TJ frame swap."

- Jeep Forums & Groups: Dedicated Jeep Wrangler forums and Facebook groups often have "for sale" sections where members list parts, including frames. These communities can also offer valuable advice.

- Salvage Yards & Auto Recyclers: Call local and regional salvage yards. They often acquire wrecked Jeeps and may part them out.

- Aftermarket Retailers: For new reproduction frames, check with major aftermarket Jeep parts retailers or directly with manufacturers like Throttle Down Kustoms.

- Local Jeep Clubs: Networking with local Jeep enthusiasts can lead to leads on frames from fellow members or their contacts.

- Patience: Finding the right frame at the right price can take time, especially for used options. Don’t rush into a purchase.

Potential Challenges and Solutions

- High Shipping Costs: Solution: Prioritize local pickup, or be prepared to budget significantly for freight. Consider splitting costs with a friend if buying multiple large items.

- Hidden Damage: Solution: Thorough inspection (in-person if possible), request extensive photos/videos, ask for a detailed description of any repairs, and buy from reputable sellers with return policies.

- Legal Hurdles: Solution: Research your state’s DMV laws before purchasing. Consult with a title service if unsure.

- Fitment Issues (Aftermarket): Solution: Buy from well-known manufacturers with good reputations. Check reviews specifically for fitment. Be prepared for minor modifications.

- Finding a Reputable Seller: Solution: Check seller reviews, ask for references, communicate extensively, and trust your gut. If a deal seems too good to be true, it probably is.

Price Table: Estimated Costs for Jeep TJ Frames For Sale

| Frame Type | Description | Estimated Price Range (USD) | Factors Influencing Price |

|---|---|---|---|

| Used OEM Frame | Salvaged from another TJ, condition varies greatly. | $500 – $2,000 | Condition (rust, damage), location, included components (e.g., axles), seller urgency. |

| Refurbished OEM Frame | Used frame that has been stripped, repaired, sandblasted, and coated. | $2,000 – $4,000+ | Extent of refurbishment, quality of coating, included components, reputation of the shop. |

| New Aftermarket Frame | Brand-new reproduction frame, often with improved materials/design. | $3,500 – $6,000+ | Manufacturer, material thickness, specific design features (e.g., V8 mounts), included components (bare vs. fully dressed). |

| Galvanized Frame | New or refurbished frame that has undergone hot-dip galvanization for rust protection. | $5,000 – $8,000+ | Origin (domestic vs. import), level of completion (bare vs. full mounts), manufacturer. |

| Shipping Costs | Freight shipping for a full frame. | $300 – $1,500+ | Distance, carrier, specific services (e.g., liftgate delivery), fuel surcharges. |

Note: Prices are estimates and can fluctuate based on market demand, economic conditions, and specific features.

Frequently Asked Questions (FAQ) about Jeep TJ Frames For Sale

Q1: Is it legal to replace my Jeep TJ frame?

A1: Yes, in most states, it is legal to replace a frame. However, laws vary regarding VIN transfer and titling. Some states may require an inspection and issue a "reconstructed" or "assembled" title. Always check with your local Department of Motor Vehicles (DMV) or equivalent agency before starting the project.

Q2: How much does a professional frame swap cost?

A2: A professional frame swap can be very expensive due to the significant labor involved. Expect costs to range from $5,000 to $10,000 or more, in addition to the cost of the frame itself. This estimate can vary widely based on shop rates, the complexity of your build, and any unforeseen issues.

Q3: Can I repair a rusted TJ frame instead of replacing it?

A3: Minor surface rust can be addressed, but extensive frame rot, especially in critical structural areas (like control arm mounts or body mounts), is dangerous and often not safely repairable with simple patches. While some shops offer frame repair services, a full replacement is often the safer and more durable long-term solution for severe rust.

Q4: What tools do I need for a DIY frame swap?

A4: At a minimum, you’ll need a well-equipped garage, a sturdy engine hoist or body lift, multiple heavy-duty jack stands, a comprehensive set of metric and standard wrenches/sockets, air tools (impact wrench, grinder), a torque wrench, and potentially a welder for minor modifications or component transfer. Experience and a helper are invaluable.

Q5: How long does a Jeep TJ frame swap take?

A5: For an experienced DIY mechanic working consistently, a frame swap can take several weeks to a few months. For a professional shop, it might take 2-4 weeks, depending on their schedule and the complexity of the job. It’s a time-consuming process.

Q6: Should I buy a bare frame or one with components?

A6: A bare frame is cheaper but requires you to transfer or buy all mounts, crossmembers, and other small components. A frame with components (e.g., body mounts, suspension mounts pre-welded) saves significant time and effort, but will be more expensive. Your budget, fabrication skills, and desired level of customization will dictate the best choice.

Conclusion: A Solid Foundation for Future Adventures

The pursuit of Jeep TJ frames for sale is a testament to the enduring legacy and robust design of the Wrangler TJ. For many owners, replacing a compromised frame isn’t just a repair; it’s an investment in the future of their beloved vehicle, opening doors to renewed adventures, enhanced safety, and custom modifications. While the process of acquiring and swapping a frame is undoubtedly challenging, the rewards – a solid, rust-free foundation for your iconic off-roader – are immeasurable.

By carefully considering the type of frame, meticulously inspecting its condition, understanding the associated costs, and planning the replacement process, you can navigate the market for Jeep TJ frames for sale with confidence. Whether you opt for a carefully sourced used frame, a meticulously restored OEM option, or a brand-new aftermarket masterpiece, securing a robust foundation ensures your TJ continues to conquer trails and turn heads for years to come. Your Jeep’s next chapter starts with a strong frame.