New Jeep Frames For Sale: Rebuilding the Legend, One Chassis at a Time

New Jeep Frames For Sale: Rebuilding the Legend, One Chassis at a Time jeeps.truckstrend.com

The Jeep – an icon of adventure, rugged utility, and unparalleled freedom. For generations of enthusiasts, owning a Jeep isn’t just about driving; it’s about a lifestyle, a connection to the open road, and the thrill of off-road exploration. But even the most robust vehicles eventually show their age, particularly where the rubber meets the road, or more accurately, where the body meets the frame. Rust, accident damage, or the desire for a stronger foundation for extreme modifications can lead many Jeep owners to a critical decision: should I part ways with my beloved rig, or embark on the ultimate restoration or custom build?

This is where the concept of "New Jeep Frames For Sale" becomes not just relevant, but absolutely vital. A vehicle’s frame is its very skeleton, the structural backbone upon which every other component rests. Replacing a compromised frame with a brand-new one offers a lifeline to countless Jeeps, transforming them from potential scrapyard candidates into renewed, safer, and often more capable machines. This comprehensive guide will delve into everything you need to know about purchasing a new Jeep frame, from understanding your options to navigating the complexities of the replacement process, empowering you to keep your legendary ride on the trails for years to come.

New Jeep Frames For Sale: Rebuilding the Legend, One Chassis at a Time

Why Choose a New Jeep Frame? The Foundation of Revival

Investing in a new Jeep frame is a significant undertaking, but the benefits often far outweigh the challenges, especially when compared to attempting extensive repairs on a severely damaged or rusted original.

- Uncompromised Structural Integrity: The most compelling reason. A new frame guarantees a solid, uncompromised foundation, free from hidden rust, accident kinks, or metal fatigue. This is crucial for safety, vehicle handling, and longevity.

- Enhanced Safety: A strong frame ensures that in the event of an impact, the vehicle’s crumple zones and occupant protection systems can function as designed. Rust and damage severely compromise this.

- Optimal Performance: A straight, true frame is essential for proper suspension geometry, steering alignment, and overall vehicle handling. A new frame eliminates the "crab walk" or unpredictable handling often associated with bent or twisted chassis.

- Precision Restoration: For classic Jeep models (CJ series, early YJs), a new frame allows for an authentic, body-off restoration, bringing the vehicle back to its original factory specifications or better.

- Custom Build Potential: For those planning extreme off-road builds, engine swaps, or heavily modified suspensions, an aftermarket new frame provides the ideal starting point, often featuring reinforced sections, optimized mounting points, and greater material thickness than OEM designs.

- Long-Term Value: While the initial investment might seem high, a new frame significantly extends the life of your Jeep, preserving its value and ensuring it remains a dependable vehicle for decades.

Compared to sourcing a used frame, which often comes with unknown history, hidden rust, or potential collision damage, a new frame offers peace of mind and a clean slate for your build.

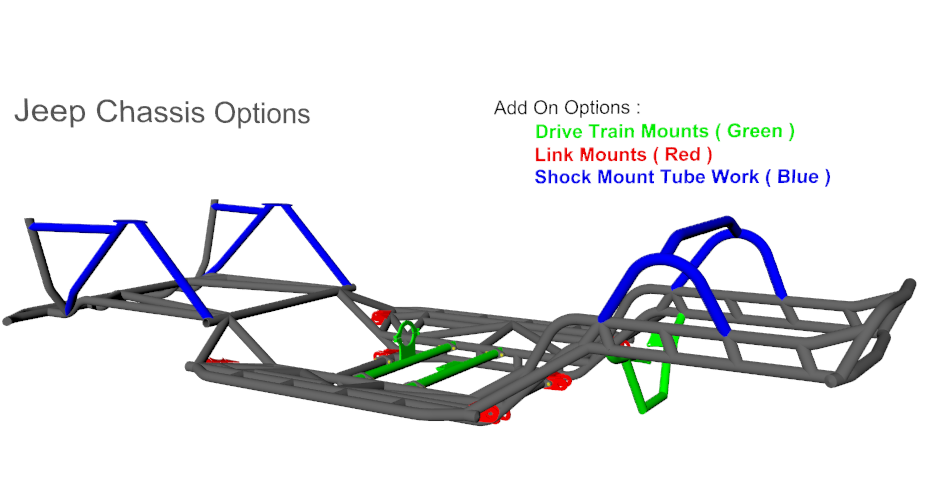

Types of New Jeep Frames Available

The market for new Jeep frames caters to a variety of needs, from direct factory replacements to heavy-duty performance upgrades. Understanding these categories is crucial for making the right choice.

-

OEM-Style Replacement Frames:

- Description: These frames are designed to be direct, bolt-on replacements for specific Jeep models and years, replicating the original equipment manufacturer (OEM) specifications. They typically match the original dimensions, material thickness, and mounting points.

- Manufacturers: Companies like Omix-ADA (through their Rugged Ridge and Crown Automotive brands), Quadratec, and other specialized aftermarket suppliers produce these. Some might be officially licensed, while others are high-quality reproductions.

- Ideal For: Restorations, collision repairs where the original frame is unsalvageable, or for those who want to maintain their Jeep as close to stock as possible.

- Compatibility: Available for a wide range of popular models, including CJ series (CJ-5, CJ-7, CJ-8 Scrambler), YJ Wranglers, and TJ Wranglers. Availability for JK and JL Wranglers as standalone new frames is less common from aftermarket suppliers, as these are newer and often repaired by dealerships or specialized body shops using factory parts.

-

Heavy-Duty Aftermarket Performance Frames:

- Description: These frames go beyond OEM specifications, offering enhanced strength, rigidity, and often improved designs for specific applications. They might feature thicker steel, fully boxed sections (instead of open C-channels), additional crossmembers, or integrated mounts for specific suspension or drivetrain upgrades.

- Manufacturers: Companies like Throttle Down Kustoms (TDK), GenRight Off Road, and various custom fabrication shops specialize in these.

- Ideal For: Serious off-roaders, rock crawlers, those planning V8 engine swaps, or anyone seeking a virtually indestructible foundation for extreme modifications.

- Compatibility: Primarily available for older, more customizable Jeep platforms like the CJ, YJ, and TJ, where extensive modification is common.

-

Custom Fabricated Frames:

- Description: While not typically "for sale" off-the-shelf, it’s worth noting that some high-end custom builds involve entirely bespoke frames built from scratch by specialized fabricators. These are tailored to unique specifications, often for competition vehicles.

When browsing, always verify the specific Jeep model (CJ, YJ, TJ, JK, JL), year, and sometimes even engine/transmission configuration to ensure perfect fitment.

Key Considerations When Buying a New Jeep Frame

Purchasing a new frame is a significant investment that requires careful thought and planning.

- Material Quality and Construction:

- Steel Gauge: Thicker steel (lower gauge number) generally means a stronger frame. OEM replicas aim for original thickness, while heavy-duty frames will be thicker.

- Welding Quality: Inspect welds for consistency, penetration, and lack of porosity. Good welding is paramount for structural integrity.

- Coating: Most new frames come with a protective coating, typically an e-coat (electrophoretic deposition) primer or a durable powder coat. This prevents rust during shipping and provides a good base for further finishing.

- Compatibility and Fitment:

- Model and Year Specificity: Double-check that the frame is designed for your exact Jeep model and year. Even slight variations can lead to major headaches.

- Mounting Points: Confirm that all body mounts, suspension mounting points (control arm mounts, shock mounts), engine mounts, transmission mounts, and steering box mounts align perfectly with your existing components.

- Drivetrain Compatibility: If you’re planning an engine or transmission swap, ensure the frame can accommodate it or is designed to be easily modified.

- Legal and VIN Transfer Implications:

- VIN Stamping: New frames typically come blank, without a Vehicle Identification Number (VIN). This is a critical legal aspect. You will need to legally transfer your original VIN from the old frame to the new one, or apply for a new VIN, depending on your state or country’s regulations. This process can be complex and may require inspection by law enforcement or DMV officials. Always research your local laws before proceeding.

- Shipping and Handling:

- Size and Weight: Frames are large, heavy, and awkward to ship. Expect significant freight costs.

- Delivery Logistics: Ensure you have a suitable location for delivery (e.g., a commercial address with a loading dock or forklift access, or arrange for residential liftgate service).

- Inspection Upon Arrival: Thoroughly inspect the frame for any shipping damage before accepting delivery.

- Manufacturer Reputation and Warranty:

- Research the frame manufacturer and seller. Look for reviews and testimonials.

- Understand the warranty offered on the frame, covering manufacturing defects.

- Budget Beyond the Frame: Remember the frame cost is just one part of the total. Factor in shipping, additional hardware (body mounts, suspension bolts), and significant labor costs if you’re not doing the work yourself.

The Frame Replacement Process: A Blueprint for Success

Replacing a Jeep frame is a major undertaking, often referred to as a "body-off restoration" or "frame-off build." It requires significant mechanical aptitude, specialized tools, and a dedicated workspace.

- Preparation and Disassembly:

- Documentation: Take countless photos and videos during disassembly. Label every wire, hose, and bolt. This is your most valuable asset during reassembly.

- Fluid Draining: Drain all fluids (fuel, oil, coolant, brake fluid, transmission fluid, differential fluid).

- Body Removal: Disconnect all wiring, fuel lines, brake lines, steering components, and exhaust from the body. Remove the body mounting bolts. Use a suitable lift or multiple strong individuals to carefully lift the body off the old frame and set it aside on sturdy stands.

- Component Removal from Old Frame: Disconnect and remove the axles, suspension components (springs, shocks, control arms), steering box, steering linkage, engine, transmission, transfer case, fuel tank, and any other components attached to the old frame.

- Frame Preparation and Component Transfer:

- Old Frame Disposal: Dispose of the old frame legally and responsibly.

- New Frame Inspection: Thoroughly inspect the new frame for any damage or manufacturing defects.

- Undercoating/Painting: Consider applying additional rust preventative coatings or painting the new frame before reassembly, as access will be ideal.

- Component Transfer: Meticulously transfer all components from the old frame to the new one. This includes engine and transmission mounts, suspension components, brake and fuel lines, wiring harnesses, and steering components.

- Reassembly and Alignment:

- Body Reinstallation: Carefully lower the body back onto the new frame, aligning all body mounts. Install new body mount bushings and hardware if necessary.

- Connect Systems: Reconnect all electrical, fuel, brake, and steering systems.

- Drivetrain Installation: Reinstall the engine, transmission, and transfer case.

- Suspension and Axles: Reinstall axles and suspension components.

- Alignment: Crucially, have a professional alignment performed once the vehicle is fully assembled and on its wheels. This ensures proper handling, tire wear, and safety.

- Legal Requirements:

- VIN Transfer: Follow your local Department of Motor Vehicles (DMV) or equivalent agency’s procedures for VIN transfer or new VIN assignment. This often involves inspections and paperwork.

Challenges and Tips:

- Seized Bolts: Expect to encounter rusted and seized bolts, especially on older Jeeps. Have penetrating oil, heat, and quality tools on hand.

- Unexpected Damage: You may discover additional worn or damaged components once everything is apart (e.g., worn axle bearings, cracked transmission mounts). Factor this into your budget and timeline.

- Organization: Labeling and bagging parts are critical. A clean, organized workspace saves immense time and frustration.

- Service Manual: Obtain a factory service manual for your specific Jeep model. It’s an invaluable resource for torque specifications, wiring diagrams, and disassembly/assembly procedures.

- Patience: This is not a weekend project. It will take weeks, possibly months, depending on your skill level and available time.

Where to Find New Jeep Frames For Sale

The market for new Jeep frames is specialized but accessible:

- Dedicated Jeep Parts Retailers: Large online retailers like Quadratec, Morris 4×4 Center, and ExtremeTerrain often carry new frames from reputable manufacturers.

- Specialized Aftermarket Manufacturers: Companies like Throttle Down Kustoms (TDK) and GenRight Off Road sell directly from their websites. These are often the go-to for heavy-duty or performance frames.

- Restoration Supply Companies: Businesses focused on classic vehicle restoration may also stock or source frames for older Jeep models.

- Local Off-Road Shops/Fabricators: Some local shops that specialize in Jeep builds may be able to order frames for you or even fabricate custom ones.

Always prioritize reputable sellers and manufacturers known for quality and customer support.

New Jeep Frames For Sale: Estimated Price Guide

Please note: Prices for new Jeep frames can vary significantly based on the specific Jeep model, the manufacturer, the type of frame (OEM-style vs. heavy-duty aftermarket), current material costs, and shipping. The table below provides estimated ranges to give you a general idea. Always obtain current quotes from suppliers.

| Jeep Model (Typical Range) | Frame Type | Estimated Price Range (USD) | Key Features/Notes |

|---|---|---|---|

| Jeep CJ-5 / CJ-7 | OEM-Style Replacement | $2,500 – $4,500 | Direct bolt-on, typically e-coated steel. Ideal for restoration. |

| Jeep CJ-5 / CJ-7 | Heavy-Duty Aftermarket | $3,500 – $6,000+ | Thicker steel, fully boxed, often with reinforced mounts. For serious off-road/V8 swaps. |

| Jeep YJ Wrangler | OEM-Style Replacement | $2,800 – $4,800 | Direct bolt-on, e-coated steel. Fits 1987-1995 YJ models. |

| Jeep YJ Wrangler | Heavy-Duty Aftermarket | $3,800 – $6,500+ | Enhanced strength, often with improved suspension geometry options. |

| Jeep TJ Wrangler | OEM-Style Replacement | $3,000 – $5,500 | Direct bolt-on, e-coated steel. Fits 1997-2006 TJ/LJ models. Popular due to TJ rust issues. |

| Jeep TJ Wrangler | Heavy-Duty Aftermarket | $4,000 – $7,000+ | Significantly stronger, often with integrated skid plates, improved coil spring/control arm mounts. |

| Jeep JK / JL Wrangler | OEM Factory Replacement | $7,000 – $12,000+ | Less common in aftermarket. Typically ordered directly from Chrysler/Jeep dealership for collision repair. |

| Shipping Costs | Varies significantly | $500 – $1,500+ | Due to size and weight, freight shipping is expensive. Varies by distance and delivery type (residential/commercial). |

Note: These prices are for the bare frame only. They do not include body mounts, hardware, suspension components, labor, or any additional parts needed for the swap.

Frequently Asked Questions (FAQ) About New Jeep Frames For Sale

Q1: Do new Jeep frames come with a VIN (Vehicle Identification Number)?

A1: No, new frames typically come blank, without a VIN stamped on them. You are legally required to transfer the VIN from your original, old frame to the new one, or apply for a new VIN through your state’s DMV or equivalent agency. This process varies by jurisdiction and usually involves an inspection.

Q2: Is it legal to replace a vehicle’s frame?

A2: Yes, it is generally legal to replace a vehicle’s frame, especially for restoration or collision repair. However, the legal procedures for VIN transfer and vehicle registration after a frame swap vary significantly by state or country. Always check with your local motor vehicle department beforehand.

Q3: How long does a frame replacement project typically take?

A3: This is a major project. For an experienced mechanic or shop, it could take several weeks of dedicated work. For a DIY enthusiast working part-time, it could easily extend to several months, especially if unexpected issues arise or you’re also doing a full restoration.

Q4: What’s the main difference between an OEM-style replacement frame and a heavy-duty aftermarket frame?

A4: OEM-style frames aim to replicate the original factory specifications for a direct bolt-on replacement, ideal for stock restorations. Heavy-duty aftermarket frames are designed for enhanced strength and durability, often using thicker steel, fully boxed sections, and modified mounting points to accommodate aggressive off-roading, larger engines, or custom suspensions.

Q5: Do I need special tools to replace a Jeep frame?

A5: Yes. You’ll need standard mechanic’s tools, but also specialized equipment like an engine hoist or body lift, sturdy jack stands, a transmission jack, air tools, and potentially cutting/welding equipment for certain modifications or seized bolts. A well-equipped garage is highly recommended.

Q6: Can I perform a frame replacement myself, or should I hire a professional?

A6: While it’s possible for an experienced and well-equipped DIY mechanic, it’s a very complex and labor-intensive job. If you lack extensive mechanical experience, proper tools, or a suitable workspace, it’s highly advisable to seek professional help from a specialized Jeep shop or restoration expert. Mistakes can be costly and dangerous.

Q7: Do new frames include body mounts or other hardware?

A7: Generally, new frames are sold as bare chassis. Body mounts, control arm bushings, shock mounts, and other small hardware items are usually sold separately or as part of a complete frame swap kit. Always confirm what is included with your purchase.

Conclusion: A New Lease on Life for Your Jeep

The decision to purchase a new Jeep frame is a significant one, but for many enthusiasts, it represents the ultimate commitment to their beloved vehicle. Whether you’re battling the relentless march of rust, recovering from an unfortunate accident, or laying the groundwork for an extreme custom build, a new frame provides an unparalleled foundation of safety, performance, and longevity.

By understanding the types of frames available, meticulously considering compatibility and legal implications, and preparing for the intricate replacement process, you can transform a tired, compromised Jeep into a revitalized, trail-ready legend. It’s more than just replacing a part; it’s about preserving a legacy, creating new memories, and ensuring your Jeep continues its adventures for decades to come, built on a foundation as solid as your passion for the open road.