Rolling Jeep Chassis For Sale: Your Blueprint for the Ultimate Custom Build

Rolling Jeep Chassis For Sale: Your Blueprint for the Ultimate Custom Build /jeeps.truckstrend.com

The allure of a Jeep is undeniable. Its rugged capability, iconic design, and boundless potential for customization have cemented its status as a legend. While many aspire to own a fully built rig, the journey often begins with a more fundamental component: a rolling Jeep chassis. Far from being just a collection of metal, a rolling chassis represents a blank canvas, a foundational blueprint upon which dream builds, meticulous restorations, and formidable off-road machines are brought to life.

This comprehensive guide will delve into every aspect of "Rolling Jeep Chassis For Sale," exploring what they are, why they’re an invaluable asset for enthusiasts and builders, how to navigate the market, and what critical considerations will ensure your project starts on solid ground. Whether you’re a seasoned fabricator or a budding DIY enthusiast, understanding the nuances of a rolling chassis is the first step towards building your ultimate Jeep.

Rolling Jeep Chassis For Sale: Your Blueprint for the Ultimate Custom Build

What Exactly is a Rolling Jeep Chassis?

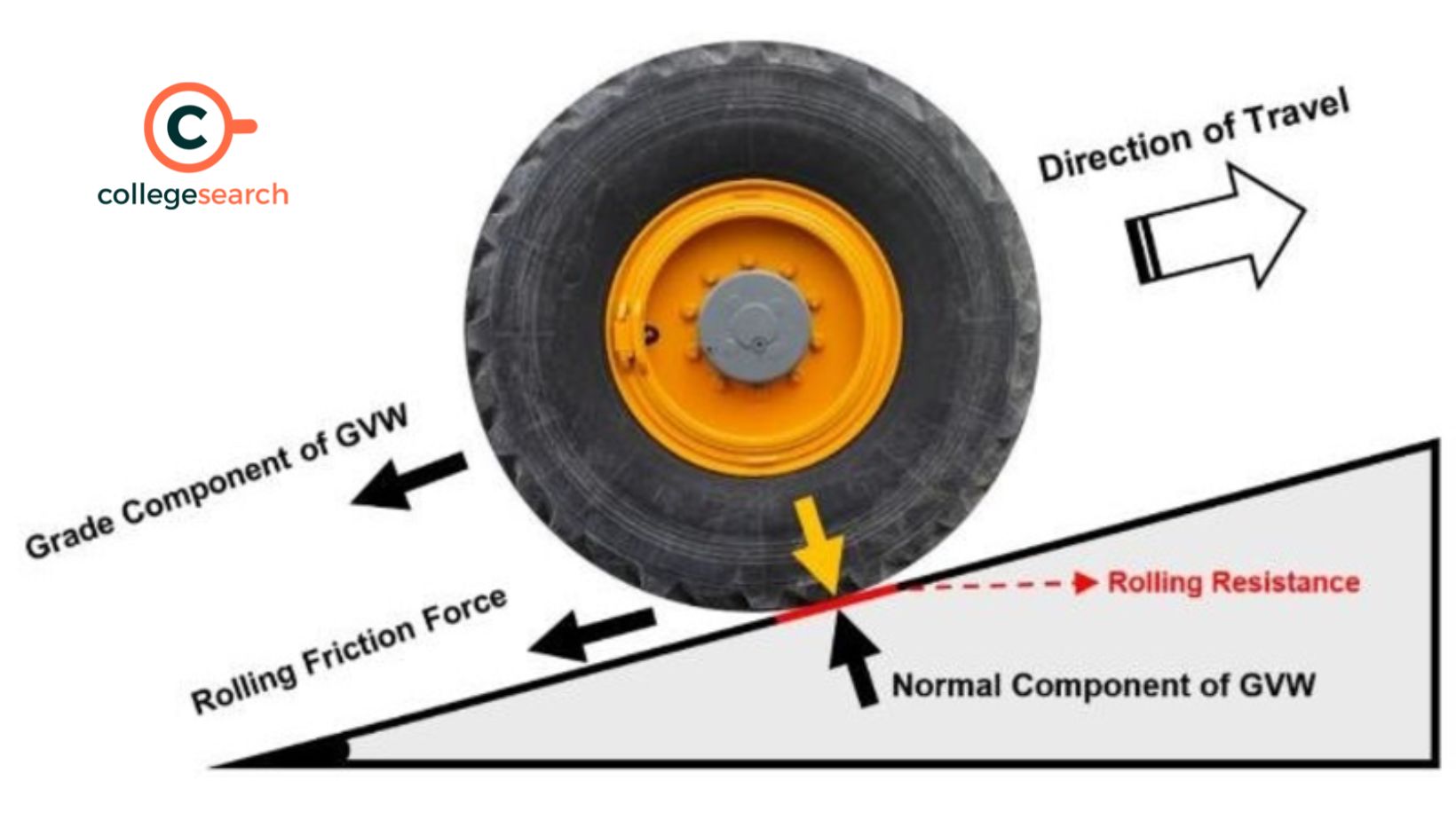

At its core, a rolling Jeep chassis is the skeletal structure of the vehicle, equipped with the essential components that allow it to "roll." It typically includes:

- The Frame: The backbone of the vehicle, providing structural integrity and mounting points for all other components.

- Axles: Both front and rear axles, complete with differential housings, axle shafts, and often gearing.

- Suspension System: Springs (leaf or coil), shocks, control arms (for coil-sprung), track bars, and sway bars (if present).

- Steering Components: Steering box, tie rod, drag link, and often the steering column.

- Braking System: Rotors, calipers, drums, and sometimes the master cylinder and brake lines.

- Wheels and Tires: While often included, their condition can vary widely, from barely usable rollers to decent trail-ready sets.

Crucially, a rolling chassis generally does NOT include the engine, transmission, transfer case, body, interior, or electrical system. It’s the robust undercarriage, ready to accept the drivetrain and body of your choice, offering unparalleled flexibility for customization.

Why Consider a Rolling Jeep Chassis? The Benefits of Building from the Ground Up

Opting for a rolling chassis over a complete vehicle might seem like a more arduous path, but it offers a multitude of compelling advantages for the discerning builder:

- Cost-Effectiveness: Often, purchasing a rolling chassis is significantly cheaper than buying a complete, running Jeep, especially one that needs extensive work. This frees up budget for higher-quality components in other areas of your build.

- Unparalleled Customization Freedom: A rolling chassis is the ultimate blank slate. You have complete control over engine swaps, transmission choices, axle upgrades, suspension geometry, and even body type. This allows for a truly unique vehicle tailored precisely to your specifications and intended use.

- Ideal for Restorations: For classic Jeep models like CJs, finding a solid, rust-free frame can be the biggest hurdle. A rolling chassis provides an excellent foundation to restore a vintage body, ensuring the underlying structure is sound and safe.

- Optimized for Off-Road Performance: Serious off-roaders often require heavy-duty axles, custom suspension linkages, and specific frame modifications. Starting with a rolling chassis allows for the installation of these high-performance components from the outset, without having to strip down an existing vehicle.

- Learning Opportunity: For DIY enthusiasts, building a Jeep from a rolling chassis provides an invaluable hands-on learning experience, fostering a deep understanding of vehicle mechanics and systems.

- Avoiding Hidden Issues: When buying a complete used Jeep, rust in hidden areas, bent frames, or undisclosed mechanical problems can be pervasive. With a rolling chassis, the critical structural components are exposed, allowing for thorough inspection and peace of mind.

Types of Rolling Jeep Chassis Available

The market for rolling Jeep chassis is diverse, reflecting the various models and build philosophies. Understanding these categories will help you narrow your search:

- By Jeep Model:

- CJ (CJ-5, CJ-7, CJ-8): These older models are popular for classic restorations and retro builds. Their frames are robust but can suffer from significant rust. Axle widths vary.

- YJ (Wrangler, 1987-1995): Distinguished by its square headlights, the YJ chassis is leaf-sprung front and rear, offering simplicity and durability.

- TJ (Wrangler, 1997-2006): The first coil-sprung Wrangler, the TJ chassis offers a more refined ride and better articulation. Highly sought after for off-road builds.

- JK/JL (Wrangler, 2007-Present): While less common as standalone rolling chassis due to their newer age and complexity, they do appear, often from salvage or highly customized projects. They offer modern conveniences and robust factory components.

- By Condition:

- Used/Salvaged: This is the most common type. Condition varies wildly from minor surface rust to heavily modified or even damaged. Thorough inspection is paramount.

- Refurbished/Restored: Some sellers offer chassis that have been stripped, sandblasted, repaired, and repainted. These command a higher price but offer a near-new foundation.

- Custom Fabricated/Aftermarket: Several companies produce brand-new, often heavier-duty frames designed for specific Jeep models or universal applications. These are ideal for extreme builds and provide superior strength and rust protection.

- By Included Components: Some sellers offer very basic chassis (frame and axles only), while others might include more complete braking systems, steering components, or even partial drivetrains. Always clarify exactly what is included.

Key Considerations Before Buying Your Rolling Chassis

Purchasing a rolling chassis is a significant investment in time and money. Careful consideration of these factors will save you headaches down the road:

- Intended Use: Will this be a daily driver, a dedicated rock crawler, a mud bogger, or a show vehicle? Your answer will dictate the required strength of the frame, the type of axles, and the suspension design.

- Budget (Beyond Purchase Price): Factor in the cost of shipping (which can be substantial), replacement parts (bushings, brakes, steering components are common wear items), and the subsequent costs of the engine, transmission, body, and all other components. Don’t forget potential labor costs if you’re not doing all the work yourself.

- Thorough Condition Assessment:

- Frame: Inspect for rust (especially around body mounts, spring perches, and welds), bends, cracks, and previous shoddy repairs. A bent or cracked frame can be extremely difficult and costly to repair correctly.

- Axles: Check for bent tubes, excessive rust on differential housings, and leaks. Inquire about gearing and whether lockers are present.

- Suspension: Examine springs for sag or breakage, shocks for leaks, and bushings for wear or cracking.

- Steering: Check for excessive play in the steering box, worn tie rod ends, and bent linkages.

- Brakes: Assume all brake components (pads, rotors, calipers, lines) will need replacement unless explicitly stated otherwise and verified.

- VIN Number: Crucial for legal registration. Ensure the VIN on the frame matches any accompanying paperwork and that the title is clear.

- Compatibility: Ensure the chassis you buy is compatible with the body you intend to use and the drivetrain you plan to install. For example, a TJ body will not directly bolt onto a YJ chassis without significant modification.

- Shipping and Transportation: A rolling chassis is large and heavy. Obtain shipping quotes early or plan for suitable transportation if picking it up yourself. This can be a major hidden cost.

The Buying Process: A Step-by-Step Guide

Navigating the market for a rolling Jeep chassis requires diligence. Follow these steps for a smoother acquisition:

- Research and Define Your Needs: Before you even look, know what Jeep model you want, your budget, and your project goals. This will prevent impulse buys.

- Locate Potential Sellers:

- Online Marketplaces: eBay, Craigslist, Facebook Marketplace are common sources, but require careful vetting.

- Specialized Forums & Groups: Jeep-specific forums (e.g., Pirate4x4, JeepForum) often have classified sections where enthusiasts sell parts.

- Salvage Yards/Auto Recyclers: Can be a goldmine, but selection is hit-or-miss.

- Custom Fabricators: For new or fully restored chassis, look to reputable aftermarket frame builders.

- Ask Detailed Questions: Don’t hesitate to bombard sellers with questions:

- "What exactly is included?"

- "What is the VIN, and do you have a clear title/bill of sale?"

- "What is the history of the chassis?"

- "Are there any known issues (rust, bends, leaks, broken parts)?"

- "Can you provide detailed photos/videos of specific areas (frame rails, welds, suspension mounts)?"

- Inspect (or Have Inspected): This is the single most important step. If possible, inspect the chassis in person. Bring a flashlight, a magnet (to check for body filler over rust), and a knowledgeable friend. If an in-person inspection isn’t feasible, ask for a video walk-around, specific close-up photos, and consider hiring a local mechanic or fabricator to inspect it for you.

- Negotiate Price: Based on condition and completeness, be prepared to negotiate. Factor in the cost of potential repairs or missing components.

- Arrange Shipping or Pickup: Coordinate logistics carefully. Ensure the seller can assist with loading if needed.

- Complete Paperwork: Ensure you receive a clear title or a proper bill of sale with the VIN. This is critical for future registration.

Building Your Dream Jeep: What Comes Next?

Once you have your rolling chassis, the real fun (and work) begins. Here’s a glimpse of the subsequent steps:

- Drivetrain Installation: Mounting your chosen engine, transmission, and transfer case. This often involves fabricating custom mounts.

- Driveshafts: Custom driveshafts will likely be needed to match your engine, transmission, transfer case, and axle setup.

- Body Mounting: Attaching the Jeep body to the frame. This might involve body lifts or minor modifications to ensure proper alignment.

- Fuel System: Installing a fuel tank, pump, lines, and filters.

- Electrical System: A complete wiring harness will be needed for the engine, lights, gauges, and accessories. This is often the most daunting part of a custom build.

- Brakes and Steering: Completing the hydraulic brake system and ensuring all steering components are tight and safe.

- Cooling System: Radiator, hoses, fan, etc.

- Exhaust System: Custom fabrication is usually required.

- Interior and Exterior: Seats, dashboard, roll cage, bumpers, winches, etc.

- Legalities: Registering your newly built vehicle with the DMV, which may involve inspections to verify VIN and safety standards.

Potential Challenges and Solutions

While rewarding, building from a rolling chassis isn’t without its hurdles:

- Hidden Damage/Rust: Even after inspection, some issues might only become apparent during disassembly.

- Solution: Budget for unforeseen repairs and have access to welding/fabrication tools or services.

- Missing or Incompatible Parts: You might discover components are missing or don’t fit your chosen setup.

- Solution: Create a detailed parts list and cross-reference compatibility before purchasing. Source parts from reputable suppliers.

- Legal Hurdles with VIN/Registration: Especially with older or custom chassis, proving ownership and registering the vehicle can be complex.

- Solution: Consult your local DMV before buying to understand their requirements for custom or rebuilt vehicles. Ensure clear title/bill of sale from the seller.

- Project Overwhelm: The sheer number of tasks can be daunting.

- Solution: Break the project down into smaller, manageable sub-projects. Celebrate small victories and seek advice from experienced builders on forums or local clubs.

Practical Advice and Actionable Insights

- Buy the Best Condition You Can Afford: It’s almost always cheaper in the long run to pay more upfront for a solid, rust-free chassis than to save money on a cheap one that requires extensive frame repair.

- Do Your Homework: Research specific model years, common issues, and compatibility of components. Knowledge is power in the custom build world.

- Budget Generously: Add at least 20-30% to your initial budget for unexpected costs, tools, and miscellaneous parts.

- Join the Community: Jeep forums, Facebook groups, and local clubs are invaluable resources for advice, troubleshooting, and even finding parts.

- Safety First: Always prioritize safety. Ensure all steering, braking, and suspension components are installed correctly and are in top working order before driving your finished Jeep.

Rolling Jeep Chassis For Sale: Estimated Price Guide

Please note: Prices for rolling Jeep chassis vary dramatically based on the Jeep model, condition, included components, and geographic location. This table provides estimated ranges for common scenarios and should be used as a general guide, not a definitive price list. Always confirm details with the seller.

| Jeep Model | Condition Category | Included Components (Typical) | Estimated Price Range (USD) | Notes & Considerations |

|---|---|---|---|---|

| Jeep CJ | Used (Fair-Good) | Frame, Axles, Leaf Springs, Steering Box, Some Brakes | $1,000 – $3,500 | Prone to rust; inspect frame extensively. Ideal for classic resto-mods. |

| Jeep YJ | Used (Good) | Frame, Axles, Leaf Springs, Steering, Brakes | $1,500 – $4,000 | Simple, robust. Check spring mounts for rust. Good budget option. |

| Jeep TJ | Used (Good-Excellent) | Frame, Axles, Coil Springs, Shocks, Control Arms, Steering, Brakes | $2,500 – $7,000 | Most popular for modern builds due to coil suspension. Frame rust near skid plate common. |

| Jeep JK | Used (Salvage/Partial) | Frame, Axles, Coil Springs, Some Suspension | $4,000 – $9,000+ | Less common as "rolling chassis." Often from accident vehicles. More complex electronics. |

| Custom Fab | New (Aftermarket) | Brand New Heavy-Duty Frame, Optional Suspension Mounts | $3,000 – $8,000+ | Frame only. Does not include axles or suspension. Built to higher specs. |

| Refurbished | Restored (Excellent) | Frame (sandblasted, painted), Rebuilt Axles, New Bushings, Some New Components | $5,000 – $12,000+ | High-quality, ready-to-build foundation. Significant labor cost included. |

Frequently Asked Questions (FAQ)

Q1: Is it always cheaper to buy a rolling chassis than a complete running Jeep?

A1: Not always. While the initial purchase price of a rolling chassis is usually lower, the total cost of building a complete, running vehicle can quickly exceed the cost of buying a used, complete Jeep, especially if you factor in the cost of a good engine, transmission, and body. It depends on your build goals and how much work you can do yourself.

Q2: What’s the single most important thing to check on a used rolling chassis?

A2: The frame. Thoroughly inspect it for rust, bends, cracks, and shoddy repairs. A compromised frame is extremely difficult and expensive to fix correctly.

Q3: Can I put any Jeep body on any rolling chassis?

A3: Generally, no. While some modifications can make certain combinations work, Jeep bodies (e.g., CJ, YJ, TJ, JK) have different body mounts, frame widths, and wheelbase lengths. Sticking to a chassis designed for your chosen body model will save immense fabrication work.

Q4: Do rolling chassis come with a VIN, and how do I register it?

A4: Yes, most rolling chassis will have the VIN stamped on the frame. It’s crucial to obtain a clear title or a properly executed bill of sale that includes the VIN. Registration procedures vary by state/country for custom-built or reconstructed vehicles, so always check with your local DMV/transport authority beforehand.

Q5: How much does it typically cost to ship a rolling chassis?

A5: Shipping costs vary widely based on distance, carrier, and fuel prices. You can expect anywhere from $500 to $2,500 or more within the contiguous United States. Always get multiple quotes.

Q6: What essential tools will I need to start a project based on a rolling chassis?

A6: At a minimum, you’ll need a good set of hand tools (wrenches, sockets), a floor jack, jack stands, an engine hoist, and potentially a welder for fabrication. Access to a well-equipped garage or shop is highly beneficial.

Conclusion

The world of "Rolling Jeep Chassis For Sale" is a gateway to automotive creativity and unparalleled customization. It offers enthusiasts a unique opportunity to build a vehicle tailored precisely to their vision, whether that’s a faithful restoration of a classic, an extreme off-road monster, or a one-of-a-kind street machine. While the journey from a bare chassis to a completed Jeep demands dedication, research, and often a healthy dose of problem-solving, the reward of driving a vehicle you’ve built from the ground up is immeasurable. With careful planning, thorough inspection, and a passion for the process, your rolling chassis will transform from a collection of metal into the foundation of your dream Jeep, ready to conquer any adventure you throw its way.