Yj Jeep Frame For Sale: The Ultimate Guide to Reviving Your Wrangler

Yj Jeep Frame For Sale: The Ultimate Guide to Reviving Your Wrangler jeeps.truckstrend.com

The iconic Jeep Wrangler YJ, produced from 1987 to 1995, holds a special place in the hearts of off-road enthusiasts and classic vehicle lovers alike. Instantly recognizable by its distinctive square headlights and robust, utilitarian design, the YJ Wrangler embodies the spirit of adventure. However, time, the elements, and the rigors of off-road excursions can take their toll, often leaving the very foundation of these beloved machines—the frame—in a state of disrepair.

For many YJ owners, the question eventually arises: what to do when the frame is compromised by rust, accident damage, or simply years of wear and tear? The answer for a growing number of enthusiasts is to seek out a "YJ Jeep Frame For Sale." This isn’t merely a transaction; it’s an investment in the longevity and structural integrity of your vehicle, a crucial step in a full restoration, a custom build, or simply bringing a cherished classic back to life. A solid frame is the bedrock of your Jeep, ensuring safety, proper handling, and the ability to withstand the demands of the trail. Without it, even the most pristine body or powerful engine is fundamentally flawed. This comprehensive guide will delve into every aspect of purchasing and utilizing a YJ Jeep frame, offering insights, practical advice, and everything you need to know to embark on this significant project.

Yj Jeep Frame For Sale: The Ultimate Guide to Reviving Your Wrangler

Understanding the YJ Jeep Frame: Anatomy and Importance

At its core, the YJ Jeep, like most traditional SUVs and trucks, utilizes a robust ladder frame chassis. This design consists of two long, parallel main rails connected by several crossmembers. It’s an independent structure that supports the entire vehicle: the body, engine, transmission, transfer case, axles, and suspension components are all bolted to this foundational skeleton.

Key Components of a YJ Frame:

- Main Rails: The two primary steel beams running the length of the vehicle.

- Crossmembers: Horizontal beams that connect the main rails, providing rigidity and mounting points for various components (e.g., transmission, transfer case skid plate).

- Body Mounts: Specific points where the Jeep’s body tub is bolted to the frame.

- Suspension Mounts: Locations where leaf springs, shocks, and sway bars attach.

- Steering Box Mount: A critical area on the driver’s side front frame rail.

- Front and Rear Frame Horns: The ends of the frame where bumpers and recovery points attach.

The importance of a sound YJ frame cannot be overstated. It is the primary structural component, responsible for:

- Safety: A compromised frame can fail under stress, leading to catastrophic accidents. It’s crucial for absorbing impact forces in a collision.

- Structural Integrity: It maintains the vehicle’s shape, preventing twists, bends, or misalignment that can affect handling and component longevity.

- Component Support: Every major mechanical component, from the engine to the axles, relies on the frame for secure mounting.

- Off-Road Capability: A strong frame is essential for handling the stresses of off-roading, including impacts, articulation, and heavy loads.

Common Issues Leading to Frame Replacement:

- Rust: By far the most prevalent issue, especially in regions that use road salt. Critical rust spots include the rear section (shackle mounts, bumper mounts), the skid plate area (where moisture and debris collect), body mounts (leading to body sag), spring perches, and around the steering box. Rust can lead to thinning steel, holes, and even complete structural failure.

- Accident Damage: Severe impacts can bend, twist, or crack frame rails, compromising the vehicle’s alignment and safety. Frame straightening is often only a temporary solution or not feasible for severe damage.

- Fatigue/Cracks: Repeated stress from heavy off-roading, large tires, or extreme modifications can cause hairline cracks or fatigue, particularly around welded areas or stress points like the steering box mount.

- Previous Poor Repairs: Patchwork or improperly executed frame repairs can weaken the structure, making a full replacement a safer and more reliable option.

Why Buy a Replacement YJ Frame? Common Scenarios

Deciding to replace your YJ’s frame is a significant undertaking, but it’s often the most logical and cost-effective solution for several common scenarios:

- Comprehensive Rust Restoration: For Jeeps from salt-belt states, the frame can often be the "death sentence" even if the body and drivetrain are salvageable. Extensive rust repair, involving cutting out and welding in new sections, can be time-consuming, expensive, and difficult to do correctly, often requiring specialized welding skills. Purchasing a solid, rust-free, or new reproduction frame offers a superior and more durable solution.

- Major Accident Damage: If your YJ has been involved in a severe collision that bent or twisted the frame, a replacement is almost always necessary. Frame damage impacts steering, suspension geometry, and overall vehicle safety, and is often irreparable to factory specifications.

- Custom Builds and Restomods: For enthusiasts looking to build a highly modified YJ – perhaps with a V8 engine swap, a long-arm suspension, or a complete overhaul – starting with a brand-new or meticulously refurbished frame provides the perfect clean slate. It allows for custom modifications, reinforcement, and painting before components are installed, ensuring a top-tier build.

- Salvage Title or Parts Jeeps: Sometimes, a YJ with an excellent body, engine, or transmission can be acquired cheaply due to a heavily damaged or rusted frame. A frame swap can turn a parts vehicle into a fully functional and valuable Jeep.

Types of YJ Jeep Frames Available for Sale

When searching for a YJ Jeep frame, you’ll encounter a few distinct categories, each with its own advantages and considerations:

-

Used/Salvaged Frames:

- Description: These are original equipment manufacturer (OEM) frames pulled from other YJs, often from drier climates where rust is less of an issue, or from vehicles damaged in ways that left the frame intact.

- Pros: Generally the most affordable option. They are OEM, meaning all original components should bolt right up without modification.

- Cons: Condition can vary wildly. They may have hidden rust, minor bends, or stress cracks that are difficult to detect without thorough inspection. You’re buying someone else’s problem, potentially.

- Inspection Tip: Always inspect in person if possible. Bring a hammer to tap for weak spots (rust), a tape measure to check for squareness, and a flashlight to look inside frame rails.

-

Refurbished/Blasted & Painted Frames:

- Description: These are used OEM frames that have undergone a restoration process. They are typically media-blasted to remove all rust and old paint, then inspected for damage, repaired if necessary, and finally coated with a durable paint or powder coat.

- Pros: Visually appealing and protected from immediate rust. The blasting process exposes any hidden flaws. Often a good balance between cost and quality.

- Cons: Higher cost than a raw used frame. The quality of refurbishment depends entirely on the seller’s process and attention to detail. Ensure repairs are done professionally.

-

New Reproduction/Aftermarket Frames:

- Description: Brand-new frames manufactured by aftermarket companies (e.g., Throttle Down Kustoms – TDK, Morris 4×4). These are built from scratch, often using thicker steel or improved designs (e.g., fully boxed sections for increased rigidity).

- Pros: No rust, no hidden damage, often stronger than OEM. A perfect foundation for a high-end restoration or custom build.

- Cons: Most expensive option. Availability can be limited, and there might be a lead time for manufacturing. Shipping costs can be substantial due to size and weight. Some minor modifications might be required to fit all OEM components perfectly, though most are designed for direct bolt-on.

-

Bare Frame vs. Rolling Chassis:

- Bare Frame: Just the frame itself. This is suitable if you plan to transfer all your existing components (axles, suspension, steering) or install all-new parts.

- Rolling Chassis: Includes the frame, axles, suspension (springs, shocks), and sometimes steering components. This can save significant time and effort if the included components are in good condition. However, it also means you’re inheriting the condition of those components, which might need replacement anyway.

What to Look for When Inspecting a YJ Frame for Sale (A How-To Guide)

Thorough inspection is paramount when purchasing a used or refurbished frame. A few hours of diligent checking can save you thousands in future headaches.

-

Rust Assessment:

- Critical Areas: Focus on the rear frame section (especially around shackle mounts and bumper mounts), the center section under the skid plate, all body mounts, and the spring perches (where leaf springs sit).

- Technique: Use a small hammer or screwdriver to gently tap suspicious areas. A dull thud or a soft spot indicates rust. A clear ring means solid metal. Look for bubbling paint, which often hides rust underneath.

- Inside Rails: Use a borescope or flashlight to peer inside the frame rails, especially near drain holes, as rust often starts from the inside out.

-

Straightness and Alignment:

- Visual Inspection: Stand at one end of the frame and look down the rails. They should be perfectly straight and parallel. Any visible bends, kinks, or twists are red flags.

- Measurements: If possible, take diagonal measurements from opposing corners (e.g., front passenger frame horn to rear driver’s shackle mount) and compare them. They should be identical. Measure the width at various points to ensure consistency.

-

Cracks and Welds:

- Common Stress Points: Carefully inspect around the steering box mount, all suspension mounting points (shackle hangers, spring perches), and where crossmembers attach to the main rails.

- Signs: Look for hairline cracks, especially in areas subjected to high stress. Check for any signs of previous welding or repair. If repairs have been made, assess the quality of the welds. Poorly done welds are weaker than the original metal.

-

Body Mounts:

- Ensure all body mounts are intact and not rusted through. These are crucial for securing the body tub.

-

VIN Matching (If Applicable):

- While the primary VIN is typically on the firewall/dash, some YJ frames may have a partial VIN stamped on them. If you’re buying a complete vehicle with a swapped frame, ensure it aligns with legal requirements in your jurisdiction. For a bare frame, ensure it’s not from a stolen vehicle – though this is rare for bare frames, it’s good practice.

The Process of Swapping a YJ Jeep Frame: A General Overview

A frame swap is a major undertaking, requiring mechanical aptitude, patience, and the right tools. Here’s a simplified overview of the process:

-

Preparation:

- Workspace: A level, spacious, and well-lit garage or workshop is essential.

- Tools: A sturdy engine hoist or gantry, robust jack stands (rated for vehicle weight), a transmission jack, a full set of metric and standard wrenches/sockets, impact gun, cutting tools (grinder, reciprocating saw), pry bars, and rust penetrant.

- Documentation: Take countless photos and videos during disassembly. Label every wire, hose, and component you remove. This will be invaluable during reassembly.

-

Disassembly:

- Disconnect Everything: This involves disconnecting wiring harnesses, fuel lines, brake lines, steering components, exhaust, and cooling system.

- Remove Drivetrain: Engine, transmission, and transfer case are typically removed as a single unit or separately.

- Remove Suspension and Axles: Unbolt leaf springs, shocks, and steering linkages. Remove the front and rear axle assemblies.

- Separate Body from Frame: Unbolt all body mounts. With the drivetrain and suspension removed, the body tub can be carefully lifted off the old frame using the hoist or multiple strong individuals.

-

Inspection and Preparation of New Frame:

- Thoroughly clean the new frame. If it’s a used or refurbished frame, apply a high-quality rust preventative coating or paint/powder coat it for long-term protection.

- Install any new frame-specific components like body mount bushings, skid plate hardware, or suspension mounts.

-

Reassembly:

- Mount Drivetrain: Install the engine, transmission, and transfer case onto the new frame.

- Install Suspension and Axles: Mount the leaf springs, shocks, and axles. This is an ideal time to upgrade your suspension or lift kit.

- Lower Body: Carefully lower the body tub onto the new frame, aligning the body mounts. Secure all body mount bolts.

- Reconnect Everything: Reconnect all wiring, fuel lines, brake lines, steering components, and exhaust. This is where your labels and photos become critical.

-

Final Checks and Adjustments:

- Torque: Ensure all bolts are torqued to factory specifications.

- Fluids: Refill all fluids (engine oil, transmission fluid, transfer case fluid, differential fluid, coolant, brake fluid).

- Brakes: Bleed the brake system thoroughly.

- Alignment: Get a professional alignment after the swap to ensure proper steering and handling.

Potential Challenges:

- Seized Bolts: Expect many bolts, especially suspension and body mount bolts, to be severely rusted and seized. Be prepared to cut, grind, and use plenty of penetrating oil.

- Unexpected Damage: You may discover worn-out components (bushings, bearings, U-joints) once everything is apart. Budget for these.

- Time Commitment: This is not a weekend project. It can take weeks or even months for a DIY enthusiast, depending on experience and available time.

Legal and Logistical Considerations

- VIN Plate: In most jurisdictions, the Vehicle Identification Number (VIN) is primarily associated with the body/firewall of the vehicle, not the frame. Therefore, a frame swap typically does not require re-titling the vehicle. However, it is CRITICAL to verify this with your local Department of Motor Vehicles (DMV) or equivalent agency, as laws vary. Some states may require an inspection or an affidavit. Never attempt to transfer a VIN plate from one vehicle to another illegally.

- Shipping and Transportation: A bare frame is large and heavy. Freight shipping can be expensive, often requiring delivery to a commercial address with a loading dock or forklift. Consider local pickup if possible.

- Ancillary Part Costs: The cost of the frame itself is only part of the equation. You’ll likely need new body mount bushings, leaf spring bushings, shackle bolts, brake lines, fuel lines, and potentially new hardware throughout. These costs can quickly add up.

- Professional Help: While a DIY project, consider hiring professionals for critical tasks like welding (if repairs are needed on the new frame) or final alignment.

Practical Advice and Actionable Insights

- Do Your Homework: Research sellers thoroughly, especially for used frames. Ask for detailed photos and videos if an in-person inspection isn’t possible.

- Don’t Underestimate the Scope: A frame swap is a huge project. Be realistic about your skills, tools, and time commitment.

- Budget Generously: Always budget for more than just the frame. Unexpected issues and necessary new components will add to the total cost.

- Safety First: Always use appropriate lifting equipment and secure jack stands. Never work under a vehicle supported only by a jack.

- Document Everything: Photos, videos, and labels are your best friends during disassembly.

- Consider Upgrades: A frame swap is the perfect opportunity to install a new lift kit, upgrade axles, or perform other modifications that are easier to do with the frame bare.

- Seek Support: Join online Jeep forums or local clubs. The community is a vast resource for advice, tips, and troubleshooting.

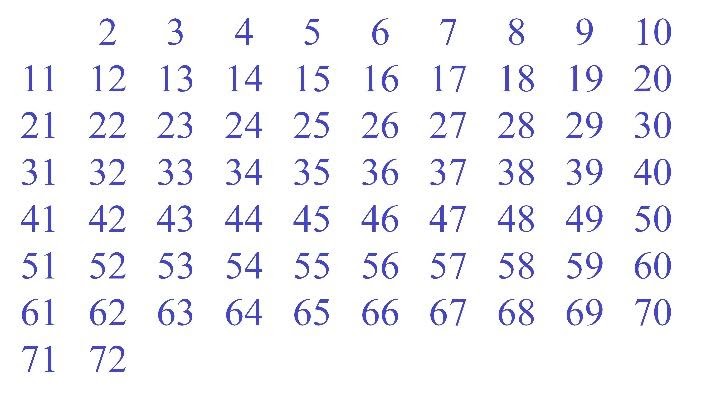

Table Price: YJ Jeep Frame For Sale – Estimated Costs

This table provides a general estimate of costs for various YJ Jeep frame options and associated expenses. Prices can vary significantly based on condition, seller, location, and market demand.

| Item | Description | Estimated Price Range (USD) | Notes